HIGH QUALITY 3D PRINTING & CNC MACHINING SERVICES

GUARANTEED PRECISION AND ACCURACY, 3-DAY LEAD TIME, ALL PARTS ARE PRODUCED IN-HOUSE IN THE EU

The worldwide largest 3D printer installation and the largest fully robotised 5-axis machining facility in Europe to create perfect customised parts for any project.

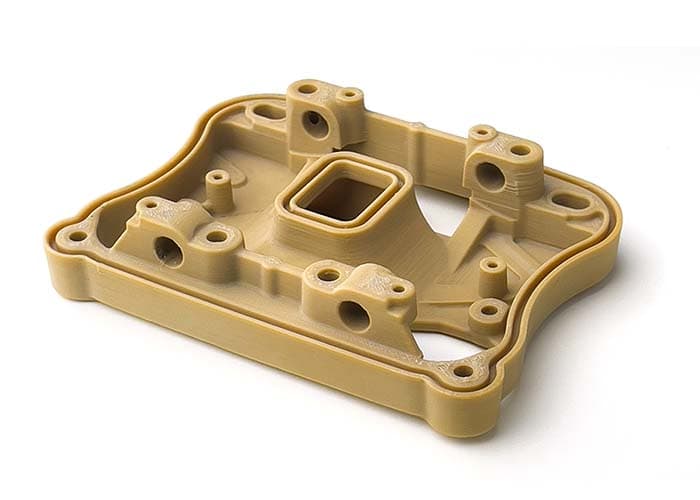

3D Printing Services

From 1 to 10.000 functional parts in 3 days.

- Quick turnaround times, in order you to get your project faster.

- High-quality materials, the highest standard for your product is always ensured.

- Great Customer Service and Support, for achieving the best result for your project.

- Cost effective, for optimal price/quality ratio. All produced in-house, in EU.

-

Available advanced MJF, FDM and MSLA 3D printing technologies.

Enjoy Instant quotes for 35+ materials

20+ post processes finishes

QUOTE IN 3 SECONDS WITHOUT COMMITMENT

DO YOU WANT TO TURN YOUR 3D PROJECT INTO REALITY?

Upload your 3D file to get one step closer to manufacturing your parts

An easy purchasing process

your Free instant quote

Upload your 3D file, choose material, finish and shipping date.

The price appears in real time and there will be no changes, you can count on it.

No surprises or hidden costs. Easy, isn't it?

In Weerg we pride ourselves on providing with fast, reliable, and amazing customer service. We believe that is what differentiates great companies from average ones.

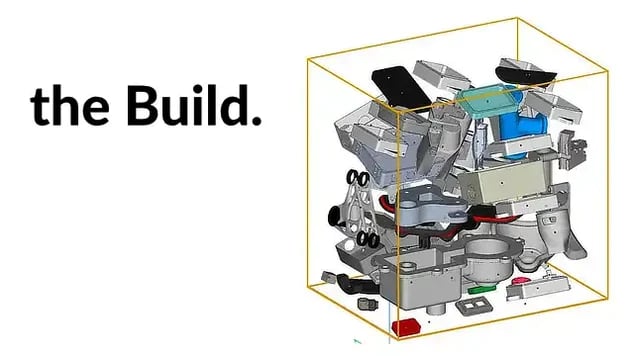

Tools for true professionals

If you are a professional who prints many parts in Nylon PA12/PA11 or Polypropylene PP by HP Multi Jet Fusion technology, the 3D build nesting can help you to obtain savings up to 60%.

How? Let's see it together:

What is 3D nesting and why the 3D build will save you up to 60%?

How to nest a 3D Build? Guide

The final cost of your pieces is clear: the price appears in real time and there will be no changes, you can count on it.

No surprises or hidden costs. Easy, isn't it?

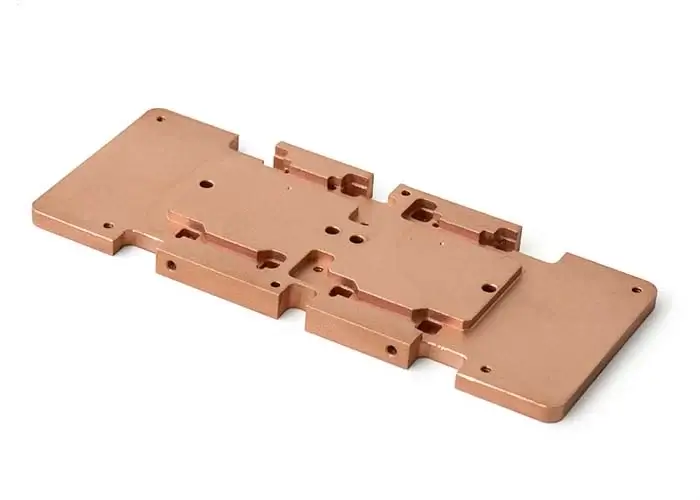

Weerg is a REAL factory

We are not resellers.

We are proud to produce and manufacture everything in house.

Your confidential files won't be shared with other suppliers.

In Weerg, you will be able to discuss directly with the technician who receives and checks your files, who produces your parts and checks or ships them: we produce your parts with passion and we all work together. Weerg establishment is in Venice, Italy.

YOUR PRICE IN 3 SECONDS

The easiest method for calculating the cost of your parts

Upload your 3D file to get one step closer to the additive manufacturing of your pieces.