| Nylon PA12 | Nylon PA12 W | Nylon PA11 | Nylon PA12 CF | Nylon PA6 CF | Nylon PA12 GB | |

|---|---|---|---|---|---|---|

| Properties | ||||||

| Tensile breaking load | 52 MPa | 44 MPa | 54 MPa | 56 MPa | 63 MPa | 31 MPa |

| Modulus of elasticity | 2 GPa | 1,6 GPa | 1,7 GPa | 8,3 GPa | 2,4 GPa | 2,9 GPa |

| Elongation at break | 15 % | 12 % | 39 % | 2,9 % | 8 % | 7 % |

| Flexural modulus | 1730 | 1800 | 1400 | 3532 | 5224 | 2400 |

| HDT 0.45 MPa | 175 °C | 175 °C | 185 °C | 128 °C | 179 °C | 171 °C |

| Izod impact resistance | 3,5 kJ/m2 | 3,5 kJ/m2 | 7 kJ/m2 | 12,1 kJ/m2 | 12 kJ/m2 | 3,6 kJ/m2 |

| Features | ||||||

| Price range | € € € € € | € € € € € | € € € € € | € € € € € | € € € € € | € € € € € |

| Lead time | <2 days | <10 days | < 5 days | <3 days | <3 days | < 5 days |

| Quote | Quote | Quote | Quote | Quote | Quote | |

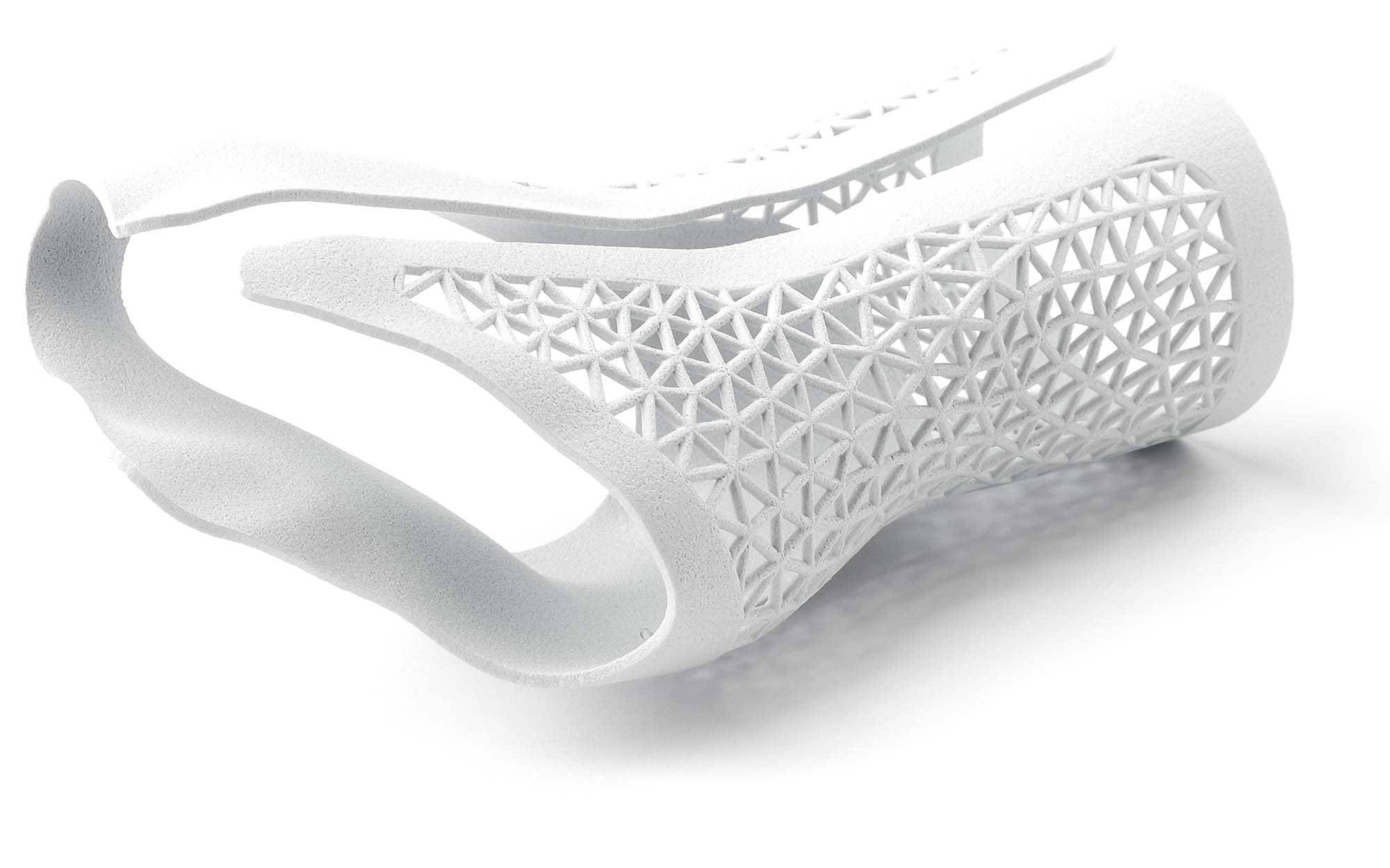

Nylon 3D printing

A material that offers superior strength and durability for applications where precision and reliable performance are essential

All uploads are encrypted end-to-end

6 different nylons 3D printed, each with its own unique characteristics and advantages

compare the properties

At Weerg we pride ourselves on providing fast, reliable, and amazing customer service. We believe its what separates great companies from average ones.