Nylon PA 12 White

Same performance as PA12, with more colour versatility

White PA 12 Nylon retains the excellent mechanical properties of classic PA12, with the added benefit of a lighter colour. This makes it easier to paint or dye, making it ideal for customised finishes and vibrant colours.

PROS

- You can dye it in numerous colours

- Mechanical properties similar to the classic PA12

- Parts are 100% full and printed without supports

- Good chemical resistance

CONS

- Parts with large flat surfaces may warp

MAIN FEATURES

- 3D printing process: MJF

- Tolerances: ±0,50mm < 100mm ; ±0,5% > 100mm

- Max size: 380 x 284 x 380 mm ; 15 x 11.2 x 15 in

- Lead time: <2 days

- Available finishes: dyeing, semi-matt and semi-gloss painting

PA 12 WHITE 3D PRINTING VIDEO GALLERY

READY FOR DYEING

White Nylon PA12 represents a new HP innovation in Multi Jet Fusion technology. This material not only retains the excellent properties of classic Nylon PA12, but also adds the ability to absorb dyes of different pigments thanks to its white colouration. This feature opens up new possibilities in the field of aesthetic customisation, allowing designers to explore a wider range of colour options without compromising the mechanical qualities of the material.

MECHANICAL PROPERTIES AND DESIGN FREEDOM

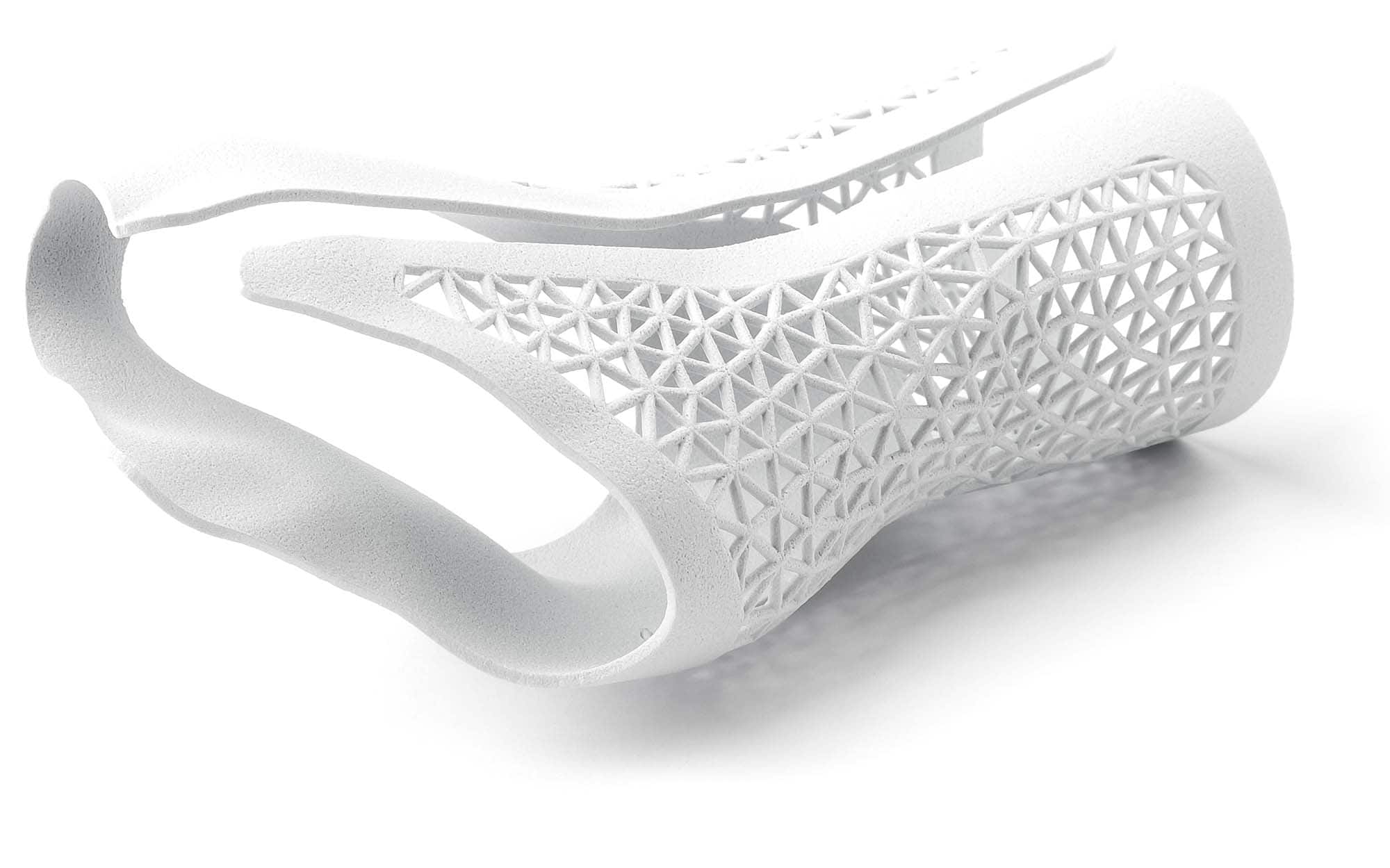

Nylon PA12 White, processed using HP Multi Jet Fusion technology, avoids the need for supports during printing, offering unprecedented design freedom. This is essential for designers wishing to explore complex shapes and geometries, while ensuring maximum part strength and durability. The combination of these mechanical properties with an advanced printing process makes it the ideal choice for the production of functional parts that require precision and reliability.

CHEMICAL RESISTANCE AND VERSATILITY

White Nylon PA12 not only offers superior chemical resistance, but it is resistant to moisture, grease and hydrocarbons too. This versatility makes it suitable for a wide range of industrial and creative applications. In addition, its low price makes it a solid alternative to injection moulding, especially when a functional material in the specific colour desired is required.

Quote now your white nylon parts

free instant quoteNYLON PA12 WHITE GALLERY

COMMENT

Nylon PA12 White, presented by Weerg, represents a significant innovation in the field of 3D printing thanks to HP Multi Jet Fusion technology. This material combines the excellent mechanical properties of Nylon PA12 with the versatility of a white colour, which can be further customised with different dyes. HP Multi Jet Fusion processing technique avoids the need for supports, giving designers unprecedented freedom in the design phase.

Pros

HP Multi Jet Fusion Technology: This advanced technology enables the printing of complex pieces without supports, offering unprecedented design freedom.

Dye-ready: The white colouring of the material is optimal for absorbing dyes of different pigments, allowing for extensive colour customisation.

Excellent Mechanical Properties: Retains the mechanical properties of classic Nylon PA12, making it ideal for functional parts requiring strength and durability.

Good Chemical Resistance: Its resistance to a variety of chemicals makes it ideal for use in industrial environments and applications requiring high durability.

Cons

Parts with large flat surfaces may deform: During 3D printing, material heating can lead to differences in cooling rates between the various areas of the item. This discrepancy may cause internal stresses, which in turn can cause parts to cool more quickly to bend or warp, a phenomenon that is particularly noticeable in parts with large flat surfaces. To prevent this distortion, known as "warpage", post-press corrective actions or modifications to the original design may be necessary to ensure dimensional stability.

Applications of PA12 White

Aerospace: Used for the manufacture of lightweight yet strong components, such as fairings and internal structural parts of aircraft, where the combination of light weight and strength is critical.

Oil and gas industry: Used to make flexible piping and equipment components resistant to oil, gas and other corrosive fluids, exploiting its excellent chemical resistance.

Automotive: Applied in the manufacture of interior and exterior vehicle parts, such as engine components, linings and gaskets, where strength and durability are required.

Sports and Leisure: Nylon PA12 White is used in the production of sports equipment, such as tennis rackets, gym equipment and bicycle parts, where the combination of strength and flexibility is essential.

Electronics: Used as an insulating and protective material for cables, connectors and housings of electronic devices, due to its resistance to temperature and chemicals.

Fashion: White nylon is used for the production of strong and lightweight accessories, such as belt buckles, glasses and shoe parts, where lightness and strength are valued qualities.

Comparison with other materials

Resin: Although resin offers very fine detail and a smooth finish, Nylon PA12 White outperforms resin in terms of strength and flexibility, making it more suitable for parts that must withstand high loads or wear.

ABS: ABS is a popular 3D printing material due to its strength and durability. However, Nylon PA12 White has greater abrasion and chemical resistance, as well as better dimensional stability, making it a better choice in many applications.

Nylon PA12: When comparing White Nylon PA12 and the classic Nylon PA12, some key differences emerge that influence the choice of material according to specific requirements. The classic Nylon PA12 is widely recognised for its excellent mechanical properties and chemical resistance, making it a reliable material for a wide range of applications. On the other hand, Nylon PA12 White brings with it the added advantage of white colouring, which not only retains all the qualities of classic Nylon PA12 but also offers the possibility of being dyed in different colours. This feature makes it particularly suitable for projects requiring not only high technical specifications, but also customised aesthetics. Both materials share similar mechanical properties, ensuring strength and durability in the applications for which they are used. However, Nylon PA12 White, due to its readiness for dyeing, proves to be a preferable choice in situations where aesthetics and colour customisation are crucial. In contrast, classic Nylon PA12 continues to be a solid option for more general applications where colouring is not a determining factor.

In conclusion, Nylon PA12 White, with HP advanced Multi Jet Fusion technology, offers a unique combination of versatility, mechanical properties, chemical resistance and colour customisation possibilities. These features make it an excellent choice for a wide range of 3D printing applications, especially when a functional material in a specific colour is required.

MATERIAL PROPERTIES

| Tensile breaking load | 44 MPa |

| Modulus of elasticity | 1600 MPa |

| Elongation at break | 12% |

| Flexural modulus | 1800 MPa |

| HDT 0.45 MPa | 175 ºC |

| Izod impact resistance | 3,5 kJ/m² |

At Weerg, we pride ourselves on providing fast, reliable and amazing customer service. We believe that this is what distinguishes great companies from others.

Questions and answers on nylon PA12 white

White Nylon PA12 retains all the excellent mechanical, thermal, and chemical properties of standard PA12, making it a versatile and high-performing material. The primary difference lies in its aesthetic qualities and customisation options provided by the white version. Thanks to its neutral colour, White Nylon PA12 can be easily dyed or painted in a wide range of shades, ensuring vivid and uniform colours. This makes it ideal for applications where product aesthetics and design are crucial. Conversely, standard PA12 is available only in raw grey or black, limiting visual customisation options and making it better suited for contexts where aesthetics are not a priority. The ability to customise White Nylon PA12 with dyeing or painting techniques makes it a preferred choice for industries such as industrial design, product design, and architecture, where the final appearance of the product plays a critical role in project success.

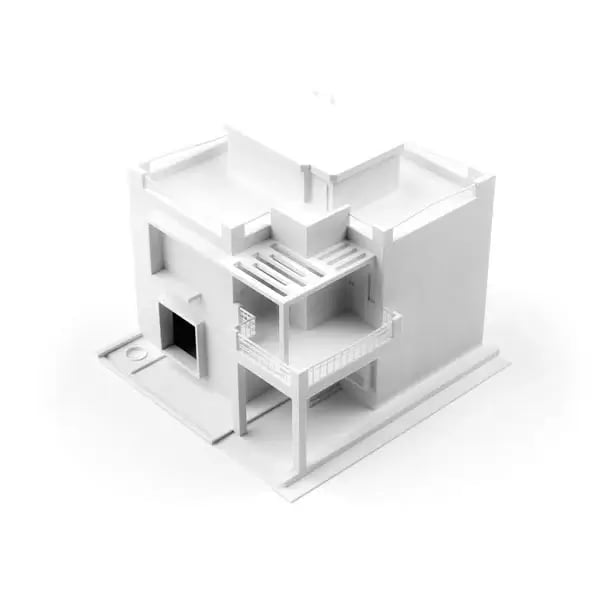

White Nylon PA12 is highly valued across various industrial sectors due to its combination of excellent technical properties and aesthetic customisation potential. One of its primary applications is in architecture, where it is used to create detailed models and prototypes representing complex architectural projects. Its ability to be coloured makes it ideal for producing models that accurately reflect the aesthetics of the final project, highlighting details and textures.

In industrial design and product design, White Nylon PA12 is selected for prototypes that must meet strict technical requirements while also presenting an appealing aesthetic. Its ability to produce smooth, uniform surfaces with customised colours allows designers to present prototypes that faithfully reflect the appearance of the final product. In the automotive sector, it is used to create aesthetic and functional components where visual appeal plays a significant role in consumer perception. Additionally, in consumer goods production, such as technological products and high-end accessories, White Nylon PA12 enables the combination of high technical performance with refined aesthetics, ensuring a significant visual impact in the market.

Parts printed in White Nylon PA12 can reach maximum dimensions of 380 x 284 x 380 mm (15 x 11.2 x 15 in), a range that allows the production of medium to large components suitable for various industrial and design applications. This capacity to create sizable parts is particularly beneficial in sectors like architecture, where complex and detailed models on a significant scale are required, or in industrial design for prototypes that need to be produced at realistic dimensions.

Regarding precision, White Nylon PA12 ensures highly reliable tolerances: for components smaller than 100 mm, the tolerance is ±0.50 mm, guaranteeing a very high level of precision for small parts. For components larger than 100 mm, the tolerance is ±0.5%, ensuring excellent accuracy even for larger projects. These parameters are essential to ensure that printed parts meet specified requirements and can be used without the need for further post-processing. This combination of maximum dimensions and precise tolerances makes White Nylon PA12 an ideal choice for applications requiring accurate details and dimensional reliability, both technically and aesthetically.

QUOTE IN 3 SECONDS WITHOUT COMMITMENT

Do you want to turn your 3D project into reality?

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quote