Laser Cutting

Precision and speed: Weerg turns your project into reality with the most innovative laser cutting service, guaranteeing fast and accurate results.

Our laser cutting service

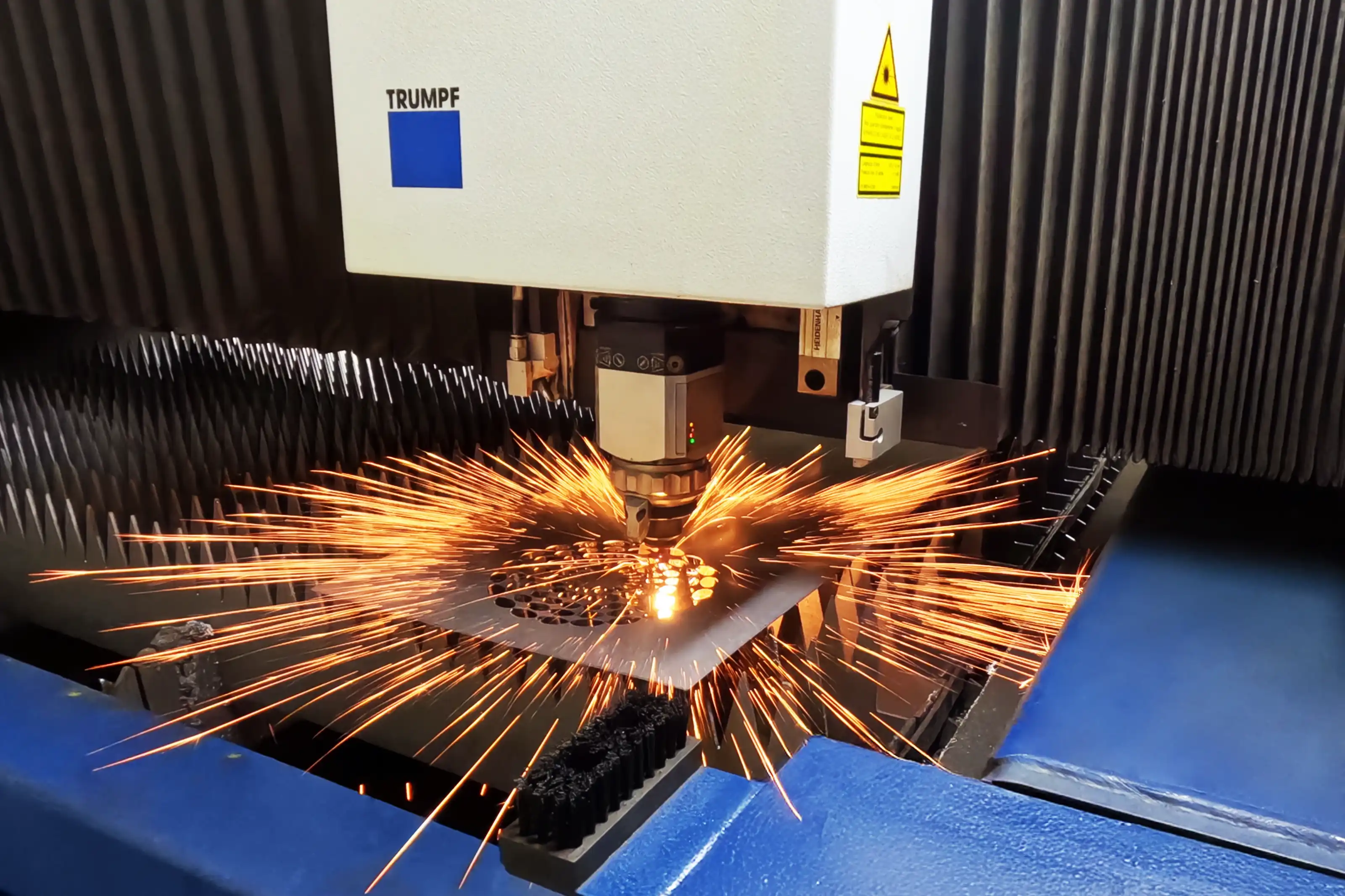

Laser cutting represents the peak of materials processing technology, combining extreme precision, efficiency and versatility in one advanced process. We use the latest and most advanced laser cutting machines, designed to handle a wide range of materials with the utmost precision. This allows us to offer laser cutting services on metal and other materials, guaranteeing superior quality results that satisfy and exceed our customers' expectations.

Available materials

An easy purchasing process

We offer an online laser cutting service that allows you to get quick and accurate quotes for your project. Using state-of-the-art fibre laser cutting machinery, we can handle projects of any size, from the production of small components to large structures.

Advantages of laser cutting

-

Precision: Laser cutting is characterised by its incredible precision, capable of generating extremely sharp edges and fine details, even in the most complex and intricate designs. This advanced technology uses a high-intensity focused laser beam that vaporises the material, allowing extremely precise cuts and minimising thermal damage to edges. This is critical for applications where precision is critical, such as in the production of mechanical components, decorative art, and the manufacture of electronic devices, where every millimetre counts. The ability to maintain flawless consistency on a large scale makes laser cutting the preferred choice for projects requiring the utmost attention to detail.

-

Versatility: The versatility of laser cutting is unparalleled, adapting to a wide range of materials with ease. From laser cutting on aluminium, known for its lightness and strength, to iron, with its robustness and durability, laser cutting offers tailor-made solutions for every need. The ability to switch from one material to another without the need to change physical tools reduces downtime and increases production efficiency.

-

Speed: One of the main advantages of laser cutting is its speed. Fast cutting processes mean that projects can be completed in considerably less time than with traditional machining methods. This efficiency is particularly beneficial in a high volume production environment where time is money. The ability to perform complex cuts in a single pass further reduces production time, allowing companies to respond quickly to market demands and reduce lead times for customers. The speed of laser cutting also improves production flexibility, allowing for last-minute changes without significantly impacting delivery times.

-

Customisation: Customisation is another strength of laser cutting. Thanks to the precision and versatility of the laser cutting machine, customised projects can be realised with ease, regardless of the complexity of the design or the small scale of production. This opens the door to endless creative possibilities, allowing designers and manufacturers to turn the most innovative ideas into tangible realities. Whether it is one-off pieces for decorative art, customised components for the automotive industry, or prototypes for new product launches, laser cutting allows for unprecedented customisation, meeting each customer's specific needs with precision and efficiency.

WEERG OBJECTIVE: quality and punctuality, always

Weerg takes care of your needs by ensuring that every part shipped is first checked and examined by a technician.

Your Free instant quote

Upload your 3D file, choose material, finish and shipping date, that's all.

The price is calculated in real time and there will be no changes, you can count on it.

No surprises or hidden costs. Easy, isn't it?

WEERG IS A REAL FACTORY

We are not resellers of other companies' parts.

That's because we enjoy making a living by producing, not by earning commissions on other people's work. We are a true CNC milling and lathing service.

Your confidential files won't be shared with third parties.

In Weerg we make your parts ourselves: you can talk to the technician who receive and check your files, who make your parts, check them or ship them: this team works with passion in the same Weerg factory, Venice, Italy.

LASER CUTTING PRICE IN 3 SECONDS

THE EASIEST METHOD TO CALCULATE YOUR LASER CUTTING PARTS COST

Upload your 3D file to take a step towards the production of your parts.