Aluminium 6082

Anticorodal: versatile, strong and easy to machine

Aluminium 6082, known as Anticorodal, is an extremely versatile alloy that combines good mechanical properties with excellent corrosion resistance. Easy to machine and weld, it is perfect for structural, mechanical and industrial applications where reliability and durability are essential.

PROS

- High corrosion resistance

- Good mechanical features

- Very good weldability

CONS

- Hard to process thin walls

- Low intrinsic fatigue resistance

MAIN FEATURES

- Machining process: CNC

- Tolerance: ISO 2768-1 fine (f) or medium (m) class. Info

- Max size: 500 x 500 x 300 mm; 19.7 x 19.7 x 11.8 in

- Lead time: <4 days

ALUMINIUM 6082 CNC MACHINED VIDEO GALLERY

High corrosion resistance

It has high corrosion resistance due to its protective oxide coat of magnesium and silicon on the surface. It is ideal for tough environments such as marine and aerospace.

excellent mechanical properties

It is ideal for structural applications due to its high strength and good weldability. It is also easily machined and commonly used in the aerospace industry for its high strength-to-weight ratio and fatigue strength for aircraft parts.

good weldability

Aluminium 6082, due to the magnesium and silicon content, has high heat resistance and good weldability. Used in construction to build a variety of structures, it forms a stable oxide coat that guarantees high quality welding and the possibility to combine it with other materials such as steel or other aluminium alloys.

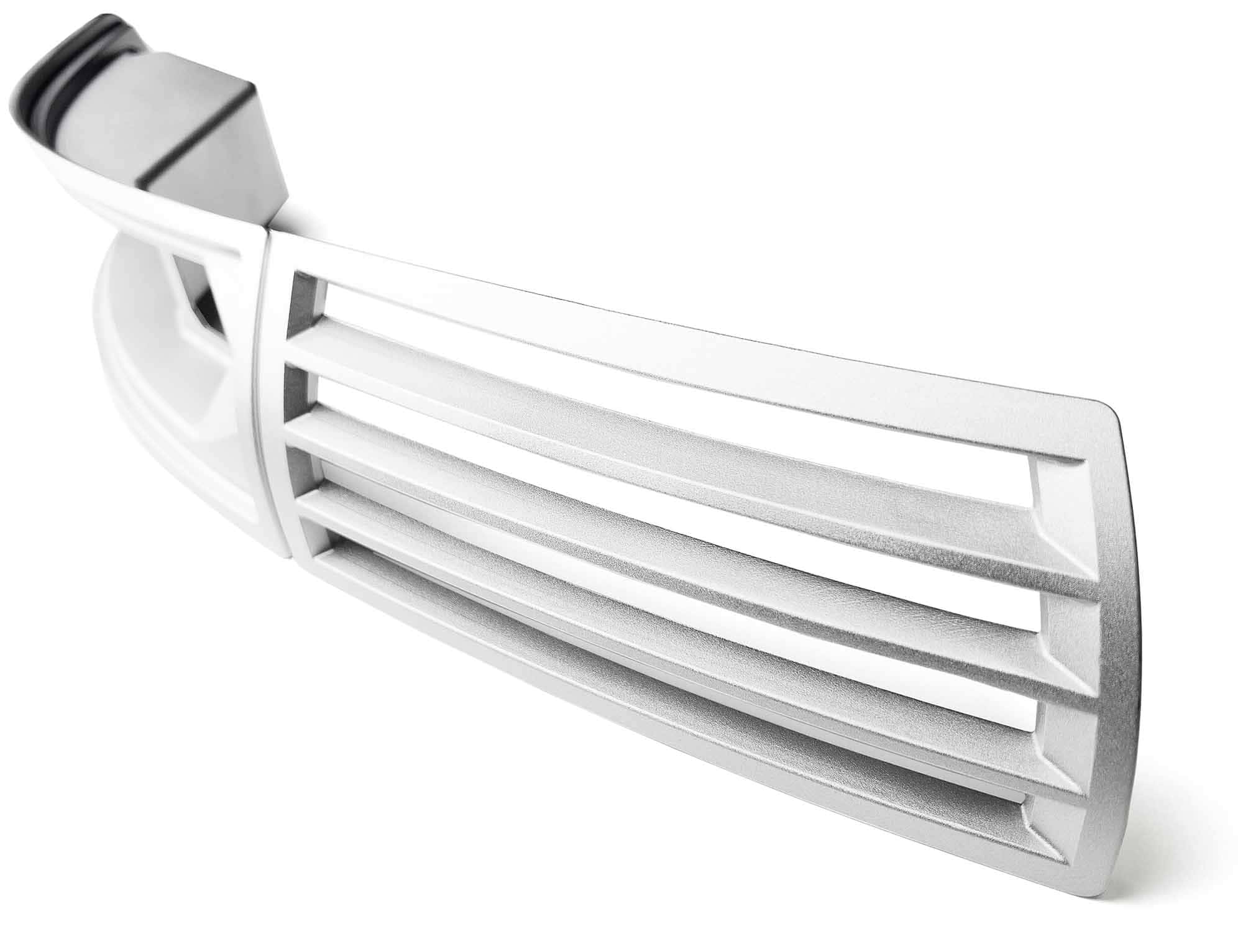

ANTICORODAL IMAGE GALLERY

QUOTE NOW YOUR ALUMINIUM 6082 PARTS

free instant quoteCOMMENT

Aluminium 6082 is an aluminium alloy with silicon as its primary alloying element. Due to its excellent machinability and weldability, this alloy has increased in popularity in a wide range of industrial applications. Its remarkable mechanical and physical properties make it an optimal choice for components that require strength, durability and precision.

Pros

High corrosion resistance: Alloy 6082 is characterised by its excellent corrosion resistance. This characteristic makes it suitable for applications in aggressive environments such as marine or industrial applications, where corrosion protection is essential for the durability of components.

Good mechanical properties: With a tensile strength of at least 295 MPa and a yield strength of at least 240 MPa, aluminium 6082 offers excellent mechanical properties. This makes it suitable for applications requiring strong and robust components, ensuring reliable and long-lasting performance.

Excellent weldability: Aluminium alloy 6082 exhibits excellent weldability, enabling the creation of high-quality welded joints. This feature is critical for many industrial applications, where welding is a common process for joining components safely and efficiently.

Cons

Difficult to process thin walls: 6082 aluminium alloy may encounter difficulties when machining thin walls. This can be an obstacle in applications where thin wall thicknesses need to be machined, as the handling of thin materials may require specialised skills and specific machining techniques to ensure accurate and consistent results.

Low natural fatigue strength: Another limitation of this aluminium is its low natural fatigue strength. This means that the material may be more susceptible to damage caused by cyclic stresses over time. This is a factor to be considered in applications subject to repeated loading or vibration, where low fatigue strength could affect the durability and life of components.

Aluminium 6082 applications

Aluminium 6082 is widely used in various sectors due to its exceptional properties and versatility.

In the transport industry, this material finds application in crucial components such as railway carriages, truck bodies and trailers. Its light weight, combined with superior corrosion resistance, makes it an ideal choice for applications requiring reliable and long-lasting performance, even in harsh environments.

In the construction industry, aluminium 6082 is used for roofing and cladding. Here, its strength and workability are exploited to create strong and durable structures that can withstand weathering and mechanical stress.

In the sporting goods and electrical industries, this alloy is used in a wide range of applications. It is used for bicycle frames and sports equipment, exploiting its high strength-to-weight ratio to ensure optimum performance and lightness. In the electrical industry, it is used for bus bars and electrical connectors, where its electrical conductivity and corrosion resistance are crucial to ensure reliable operation of electrical systems.

In conclusion, this aluminium proves to be a versatile and reliable choice in a wide range of industries due to its superior performance and ability to meet a variety of application requirements.

Conclusion

Aluminium 6082 emerges as a highly advantageous and versatile alloy for a wide range of industrial applications. Its outstanding mechanical and physical properties, combined with its excellent machinability and weldability, make it a preferred choice for components requiring strength, durability and precision.

Among its strengths, this aluminium alloy stands out for its high corrosion resistance, which makes it suitable for applications in aggressive marine or industrial environments. Furthermore, its mechanical characteristics, with considerable tensile and yield strength, make it ideal for components that must withstand high stresses over time. Its excellent weldability allows for high-quality welded joints, ensuring greater structural strength.

However, it is important to consider certain limitations, such as the difficulty in machining thin walls and low natural fatigue strength, which could pose challenges in specific applications.

Despite these limitations, aluminium 6082 finds a wide range of applications in different sectors. In the transport industry, it is used for components such as railway carriages and truck bodies, while in the construction industry it is used for roofing and cladding. In the sporting goods and electrical industries, it is used for bicycle frames, sports equipment, bus bars and electrical connectors.

In conclusion, aluminium 6082 proves to be a reliable and versatile choice, capable of satisfying a wide range of application needs thanks to its outstanding performance and flexibility of use in various industrial sectors.

"I recently had my parts made by Aluminium 6082 by Weerg and I was extremely pleased with the results. The quality of the parts was top-notch, and the price was very reasonable, considering the precision and attention to detail put into the manufacturing process."

ALUMINIUM 6082 PROPERTIES

| Tensile breaking load | 285 MPa |

| Modulus of elasticity | 69 GPa |

| Elongation at break | 6% |

| Density | 2,70 g/cm³ |

| Melting temperature | 635°C |

| Hardness | 95 Brinell |

| Yield Strength | 235 MPa |

"Not only was the quality of the parts excellent, but also the Customer Service provided in Weerg was first class. Their team was reactive and helpful throughout the process, answering all my questions and ensuring that all my needs were met."

Questions and answers

6082 aluminium is a 6000 series alloy primarily composed of aluminium with added magnesium and silicon. It is known for its excellent combination of mechanical properties, corrosion resistance, and machinability. This alloy stands out for its rigidity, making it an ideal choice for structural applications. It is often used to create components requiring good stability and moderate mechanical strength. One of the key characteristics of 6082 aluminium is its ease of machining with CNC machines, allowing the production of components with precise details and tight tolerances. The alloy offers good corrosion resistance in non-aggressive environments, such as those with moderate humidity or salinity. Additionally, the material has good fatigue resistance, making it suitable for applications subjected to repeated load cycles. Despite its advantageous properties, 6082 aluminium is not the best choice for applications requiring extremely high static mechanical values or critical dimensional stability under intense stress. In such cases, alloys like 5083 may be preferable.

6082 aluminium offers an interesting balance between strength and lightness, which are essential for many technical applications. It has a typical tensile strength of about 310 MPa and a yield strength of 260 MPa. This makes it suitable for components that need to bear moderate loads without deforming. The alloy has a Brinell hardness of about 95 HB, contributing to its wear resistance and ability to maintain performance even in challenging environments. Additionally, 6082 aluminium has good ductility, allowing the creation of complex or geometrically detailed parts without compromising mechanical properties. Regarding corrosion resistance, 6082 performs well in moderately aggressive environments, such as those exposed to humidity or mild salinity. However, for highly severe marine environments, other alloys like 5083 may be better suited.

6082 aluminium offers an excellent compromise between mechanical strength and machinability, making it ideal for applications requiring lightness, precision, and good corrosion resistance in moderately aggressive environments. Compared to 5000 series alloys like 5083, 6082 is easier to machine with CNC machines and allows for high-quality finishes. However, for applications requiring superior dimensional stability in critical conditions, such as marine or particularly harsh industrial environments, 5083 is a better choice due to its fatigue and deformation resistance. In summary, 6082 is preferable for projects that prioritise machinability and versatility, while 5083 is ideal for situations demanding long-term stability and resistance.

6082 aluminium is widely used across various industries due to its versatility and balanced properties. In the automotive sector, it is used to produce lightweight yet strong structural components, such as frames, supports, and panels. Its combination of lightness and strength makes it ideal for improving energy efficiency and reducing the overall weight of vehicles. In the aerospace sector, it is used for parts that must withstand moderate stress while maintaining the lightness required for flight. In the nautical industry, 6082 aluminium is employed for structures exposed to challenging weather conditions, thanks to its good corrosion resistance. Additionally, 6082 aluminium is highly valued in civil engineering and architecture, where it is used to produce lightweight yet robust structures and supports. It is also a frequent choice for manufacturing industrial equipment and machinery due to its machinability and ability to withstand moderate mechanical stresses.

QUOTE IN 1 SECOND WITHOUT COMMITMENT

DON'T WAIT: UPLOAD YOUR 3D FILE AND GET A QUOTE FOR YOUR PARTS NOW!

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quote