ABS Medical

ABS Medical created for use in the medical field and made using innovative FDM technologies in the room at a controlled temperature, satisfies the need for a material with the highest health certifications, which can be used in medical contexts.

PROS

- Certified as a medical device USP 88 class VI

- Possibility of sterilisation

- Good temperature resistance

- Good mechanical strength and ductility

CONS

- Only available in 'natural' colour to maintain certification

- Over time, if exposed to UV it can yellow and can be damaged

MAIN FEATURES

- 3D printing process: FDM

- Tolerance: 0,6mm<100mm; 0,75%>100mm

- Max size: 250 x 250 x 250 mm; 9,8 x 9,8 x 9,8 in

- Lead time: <3 days

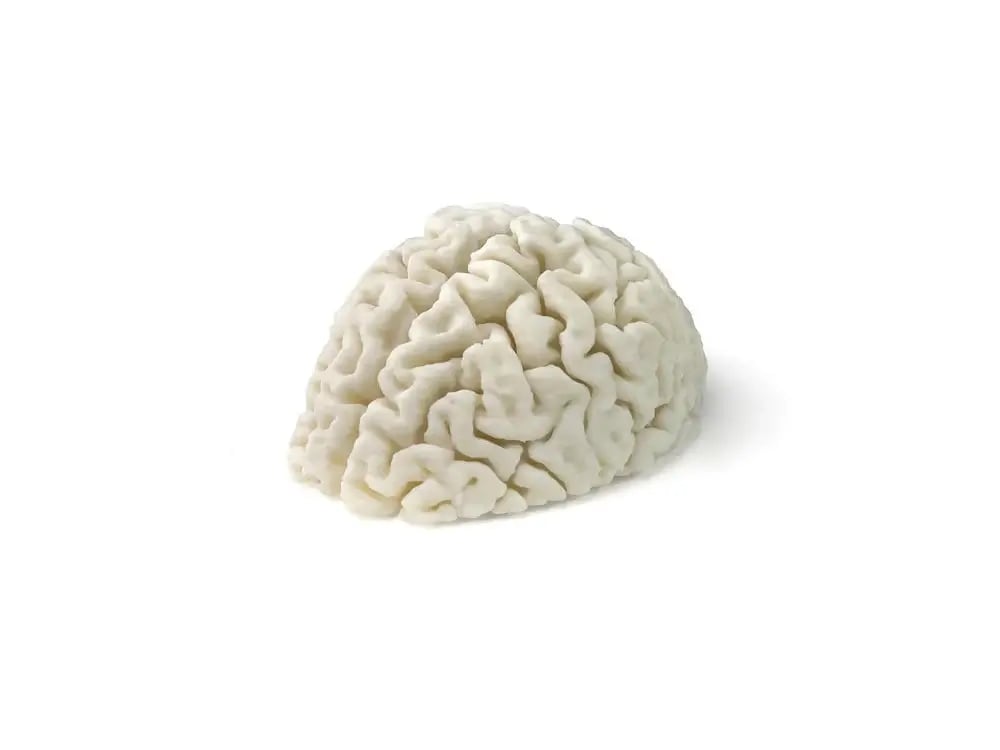

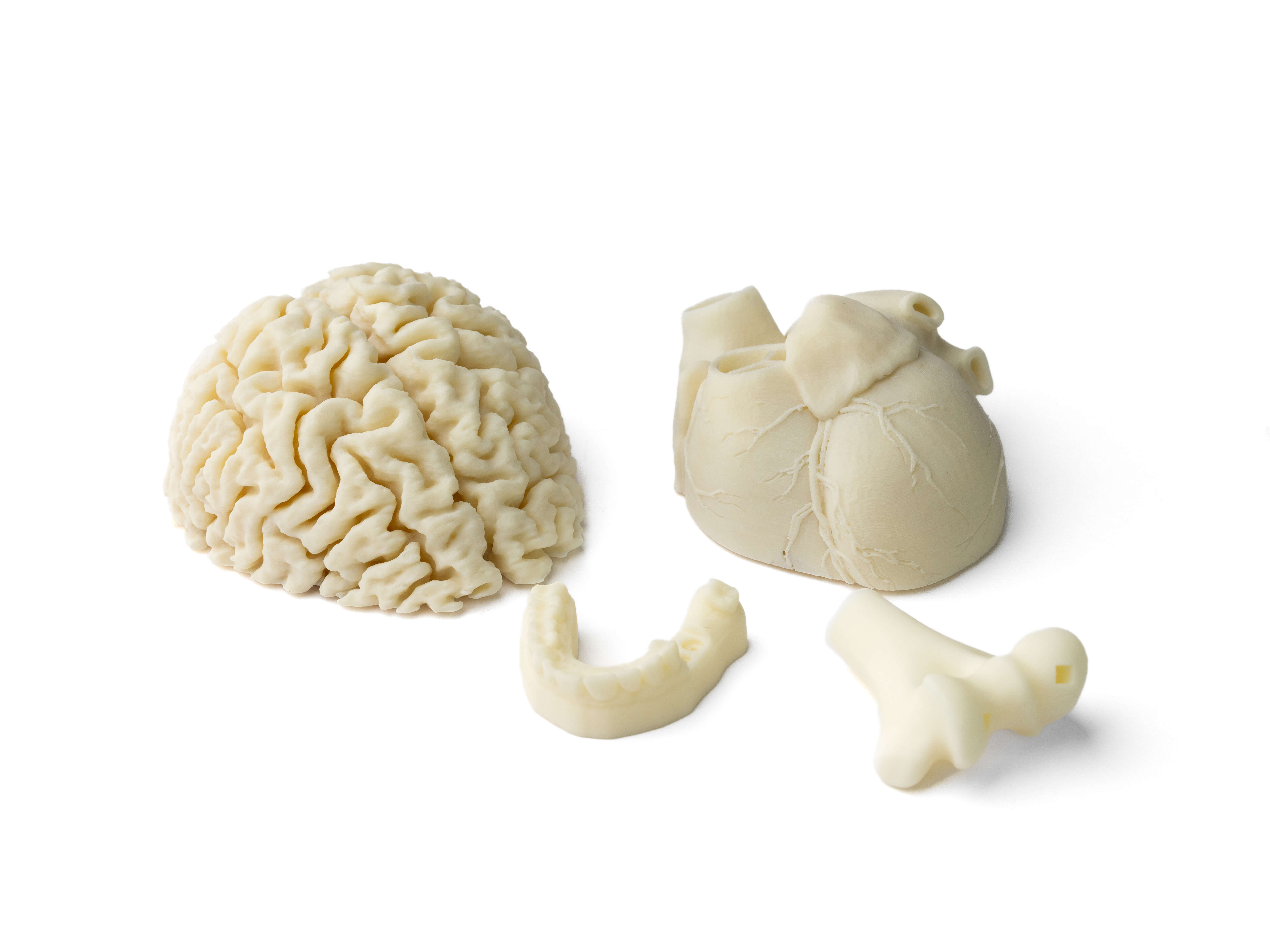

ABS MEDICAL 3D PRINTED GALLERY

QUOTE IN 3 SECONDS WITHOUT COMMITMENT

Do you want to turn your 3D project into reality?

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quoteABS MEDICAL COMMENT

Medical ABS, the result of innovation in 3D printing applied to the medical field, stands out as a certified and reliable solution. This advanced material, part of the ABS (acrylonitrile-butadiene-styrene) family, is specifically designed to fulfil the needs of the healthcare sector, finding wide use in the creation of prostheses, medical instruments and customised equipment for the well-being of patients.

Features and Production

Medical ABS is designed with a focus on maximum compatibility in the medical and healthcare environment. Manufactured through innovative FDM printing technologies in a temperature-controlled environment, it responds to the growing demand for materials that can offer the highest health certifications. This advanced manufacturing process is designed to ensure that Medical Grade ABS meets the strictest standards required in medical environments.

Pros

Certified as a medical device USP 88 class VI: ABS Medicale's main strength lies in its official certification as a medical device according to USP 88 class VI. This recognition underlines the commitment to the highest safety and quality in its use in medical applications, guaranteeing compatibility with the highest industry standards.

Sterilisation options: Medical ABS offers the flexibility of being subjected to sterilisation processes, ensuring safe use in critical medical environments. This makes it suitable for medical instruments and devices that require regular sterilisation procedures to maintain high hygiene standards.

Good Temperature Resistance: Equipped with good temperature resistance, Medical ABS maintains its mechanical stability even in contexts where temperature variations are frequent. This characteristic is crucial to ensure consistent performance in demanding medical applications.

Good Mechanical Strength and Ductility: Medical ABS offers a balanced mix of mechanical strength and ductility. This combination of mechanical properties is essential for the creation of prostheses and medical devices that must withstand varying stresses while maintaining flexibility.

Cons

Only Available in 'Natural' Colour to Maintain Certification: An important consideration in adopting ABS Medical is the limited availability of colours, limited to only 'natural', which is necessary to preserve health certifications. While this choice ensures regulatory compliance, it may be an aesthetic limitation for those seeking more varied options.

Yellowing and Damage: One aspect to consider is the potential yellowing and damage of medical grade ABS over time, especially when exposed to UV light. Although this is a common phenomenon in many plastics, it is important to carefully evaluate the impact of this aspect in medical applications, where aesthetic stability may be crucial. Evaluation becomes critical in situations where yellowing resistance and aesthetic stability are priorities, such as in long-term prostheses or devices exposed to sunlight.

Medical ABS applications

Medical ABS plays a key role in a wide range of medical contexts, demonstrating its versatility and reliability in creating customised solutions to improve the quality of care.

Customised prostheses: One of the most significant uses of this ABS is in the production of customised prostheses. Thanks to its advanced mechanical properties, this material enables the production of prostheses that are precisely tailored to the individual needs of patients. Certification as a USP 88 Class VI medical device underlines its suitability for applications requiring the highest compliance with health standards, offering a safe and reliable solution in the field of medical prosthetics.

Medical Instruments and Devices: Medical ABS is widely used in the production of instruments and devices specifically for the healthcare sector. Its resistance to temperature, combined with the possibility of sterilisation, makes it suitable for the creation of medical equipment that must withstand various environmental conditions and ensure maximum hygiene. The material's certification and physical properties help satisfy the rigorous requirements of the medical environment.

Versatility in Creating Customised Solutions: The versatility of Medical ABS is fully manifested in the creation of customised solutions for the healthcare sector. 3D printing with Medical ABS enables the production of customised devices, tailored to the specific needs of patients and healthcare professionals. This customisation can extend from the production of specialised surgical tools to customised support devices, emphasising the material's adaptability to the unique needs of the medical field.

Conclusion

In conclusion, the Medical ABS emerges as an advanced and certified solution that integrates 3D printing innovation in the medical context. Its careful design, realised using modern FDM technology in a temperature-controlled environment, reflects a commitment to the highest health certifications. This material, a member of the ABS family, is used extensively in the production of prostheses, medical instruments and customised equipment, contributing to the well-being of patients.

ABS Medical's strengths, such as certification as a USP 88 Class VI medical device and the possibility of sterilisation, place it at the top of choices for medical applications requiring safety and compliance with the most stringent standards. Its good temperature resistance, mechanical strength and ductility make it versatile, ensuring reliable performance in a variety of demanding medical contexts.

However, it is essential to carefully consider the issues that need to be controlled, such as the limited availability of colours and the effect of UV exposure over time. Despite these points, Medical Grade ABS is positioned as a key resource for those seeking advanced and certified solutions in the field of medical 3D printing. Its versatility and conformity to medical requirements make it a durable and reliable choice to satisfy the specific challenges of the healthcare sector.

MATERIAL PROPERTIES

| Tensile breaking load | 43 MPa |

| Modulus of elasticity | 1400 MPa |

| Elongation at break | 6% |

| Flexural modulus | 76 MPa |

| HDT 0.45 MPa | 81 ºC |

| Izod impact resistance | 16,1 kJ/m² |

At Weerg, we pride ourselves on providing fast, reliable and amazing customer service. We believe that this is what distinguishes great companies from others.

Questions and Answers

ABS is used in a wide range of industries thanks to its balance of mechanical properties and versatility. In the medical sector, certified ABS is employed for tools and devices that require skin compatibility and moderate chemical resistance. In the automotive industry, it is used for internal and external parts, such as dashboards, covers, and housings, due to its impact resistance and dimensional stability. In consumer goods, ABS is widely used to create cases, toys, appliances, and accessories, leveraging its workability and aesthetic finishing options. It is also popular for rapid prototyping, injection moulding, and 3D printing for the production of functional or decorative models.

No, standard ABS plastic is not naturally UV-resistant. When exposed to direct sunlight for prolonged periods, ABS tends to degrade, losing colour, becoming brittle, and developing micro-cracks. However, there are ABS variants modified with specific additives to improve UV resistance, such as those used in outdoor applications. In the case of medical ABS, UV resistance is not a priority, as the material is primarily designed for indoor and medical applications.

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic material known for its balance of mechanical properties and versatility. It offers good impact resistance, high ductility, and excellent dimensional stability. It has a glass transition temperature of approximately 105°C, which allows it to maintain its properties up to this thermal limit. It is easily machinable, suitable for 3D printing processes and other fabrication techniques. In the case of medical ABS, it has been further developed to ensure skin compatibility and suitability as a medical device, making it safe for sensitive applications. Additionally, ABS offers good chemical resistance to oils, greases, and other moderately aggressive agents.

Despite its many positive properties, ABS has some disadvantages. It is not UV-resistant, making it unsuitable for prolonged outdoor applications without specific modifications. It has limited chemical resistance to highly aggressive agents, such as certain acids or strong solvents. Additionally, ABS can deform or lose rigidity at temperatures above 105°C, making it unsuitable for extremely hot environments. Finally, the production of ABS relies on petrochemical resources, making it less sustainable compared to other biodegradable or low-impact materials.

Get your 3D printed parts in ABS medical

Upload your 3D file to get your free instant quote

free instant quote