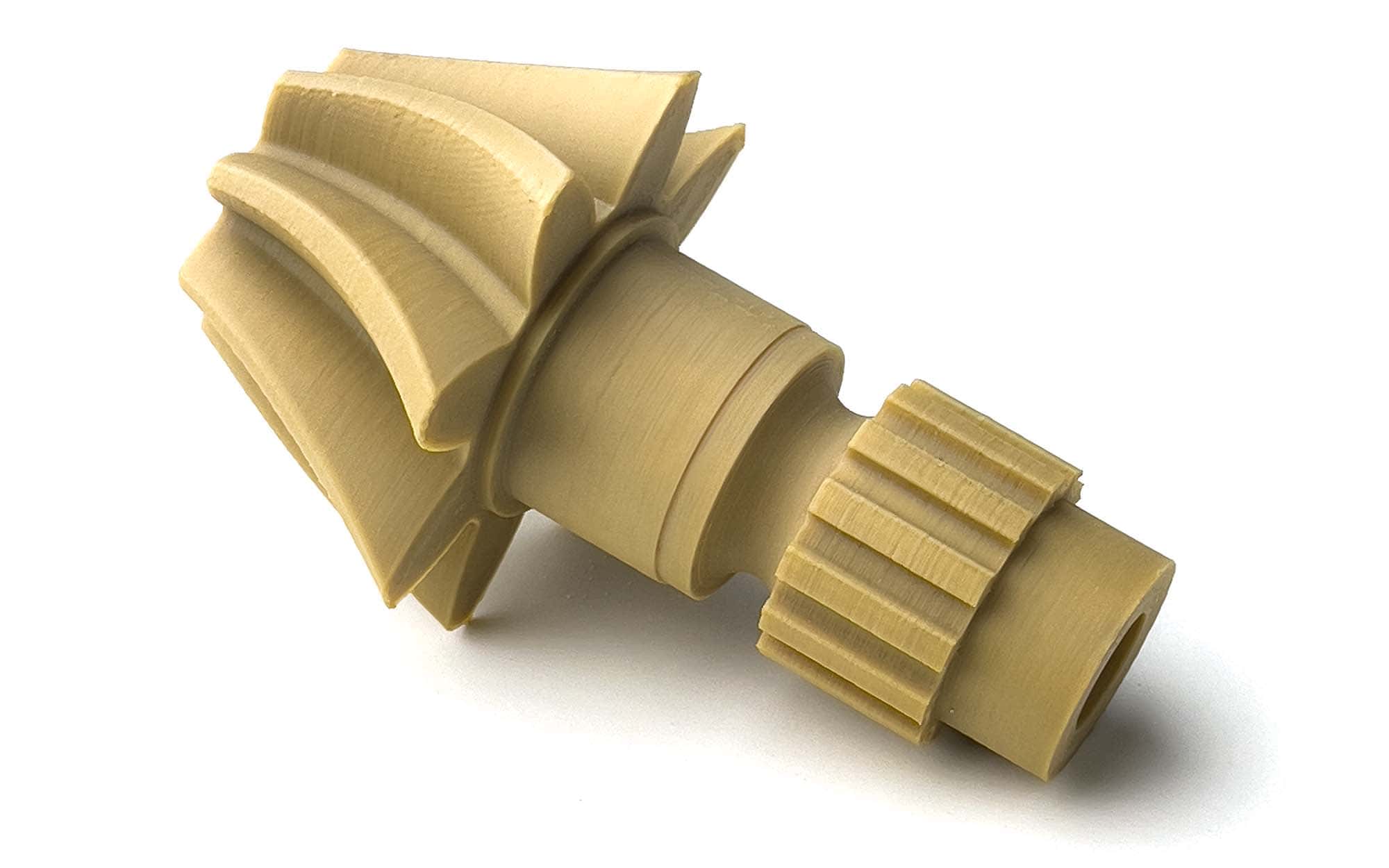

| PEEK | PEEK CF | PEEK GF | PEEK CNC | |

|---|---|---|---|---|

| Properties | ||||

| Tensile breaking load | 100 MPa | 87,4 MPa | 86,6 MPa | 101 MPa |

| Modulus of elasticity | 3,7 GPa | 8,6 GPa | 8,2 GPa | 4,4 GPa |

| Elongation at break | 3 % | 2,5 % | 2,3 % | 20 % |

| Flexural modulus | 3612 | 6338 | 5713 | 3612 |

| HDT 0.45 MPa | 180 °C | 315 °C | 299 °C | 180 °C |

| Izod impact resistance | 7,1 kJ/m2 | 9,7 kJ/m2 | 9,2 kJ/m2 | 7,1 kJ/m2 |

| Features | ||||

| Price range | € € € € € | € € € € € | € € € € € | € € € € € |

| Lead time | < 3 days | <4 days | <4 days | <3 days |

| Quote | Quote | Quote | Quote | |

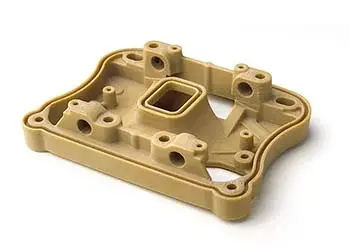

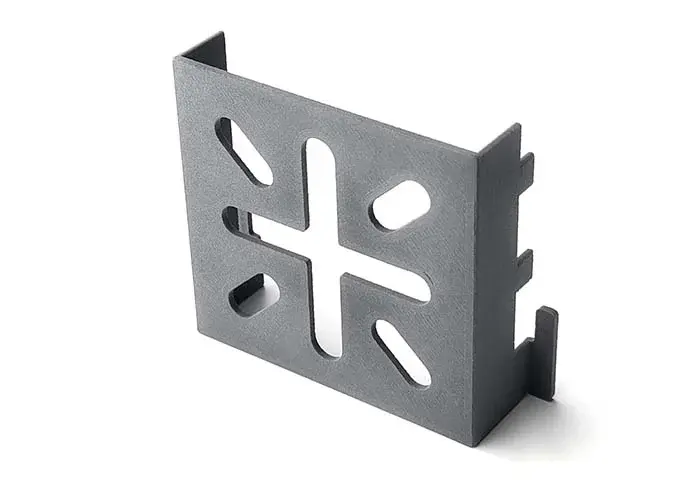

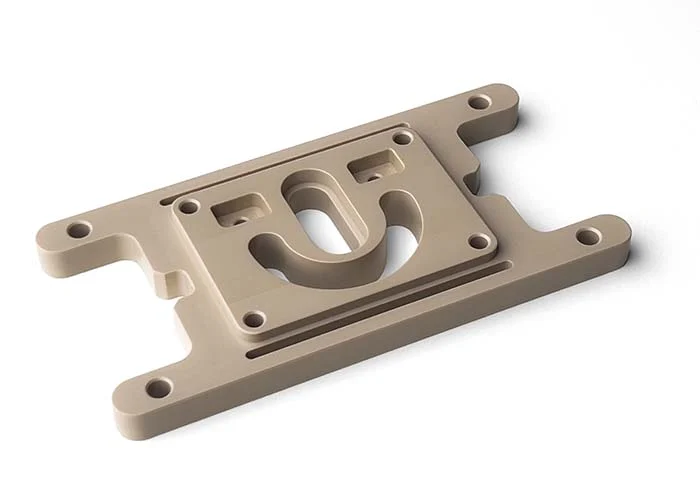

PEEK 3D PRINTING

High-performance, high-temperature super polymer family with special properties for demanding applications

All uploads are encrypted end-to-end

PEEK can have different microstructures for 3D printing and CNC

Weerg is a PEEK 3D printing and CNC machining service that helps you choose between the various PEEK materials and technologies according to the use you will have to make of your parts

Weerg offers PEEK 3D printing and CNC machining online with the best technologies; not because the seller tells us but because we do all the material tests in house.

Weerg's: online 3D printing and CNC machining with the best technologies

Weerg makes your parts in house and with the best 3D printing and CNC technologies as MJF, SLA, industrial FDM, 5 axes Lathing, Milling and Drilling.