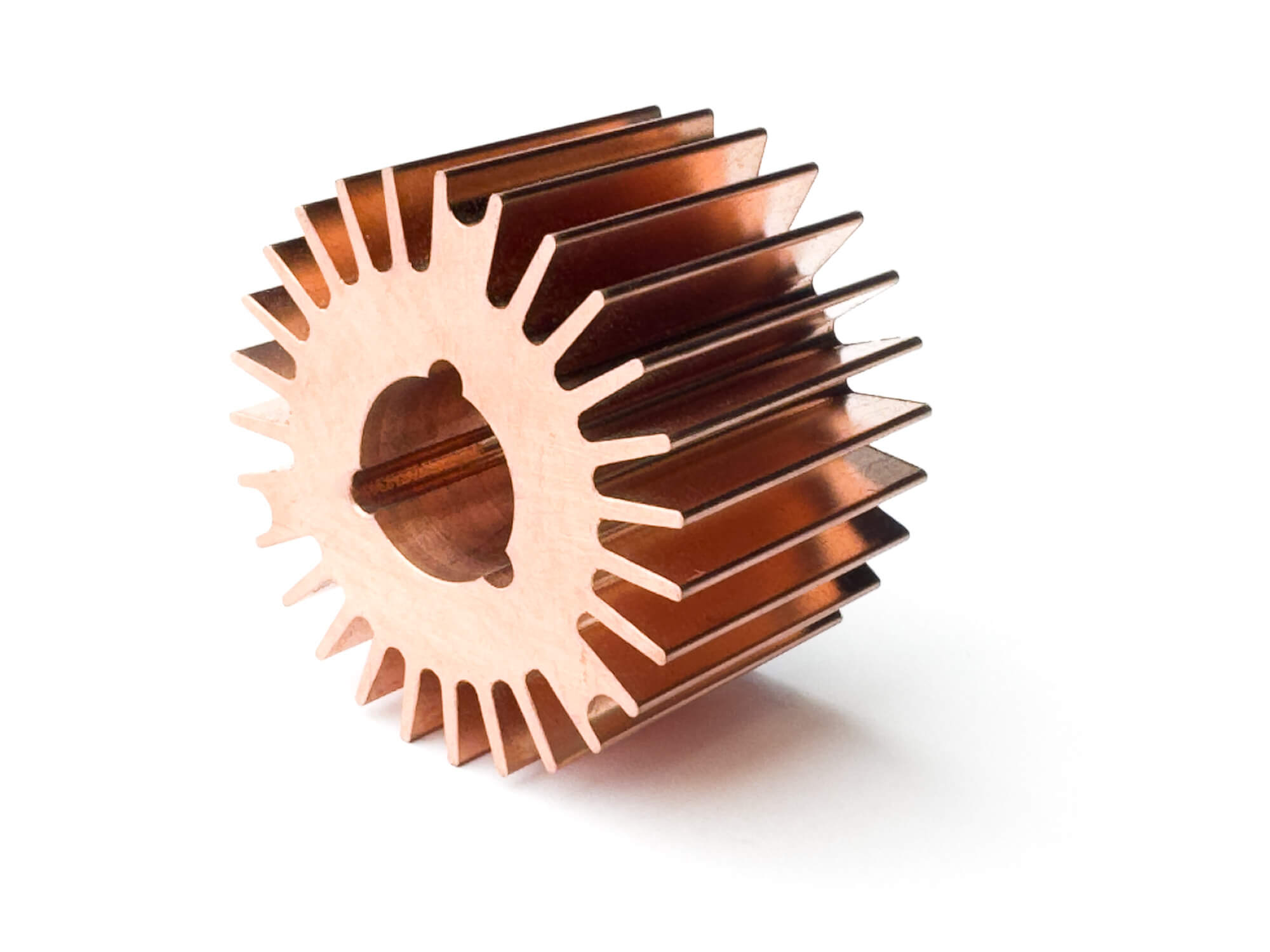

Copper C101

Excellent conductivity for electrical and thermal applications

C101 copper is an alloy with extremely high electrical and thermal conductivity, thanks to its high purity. It is the ideal choice for electronic components, electrical systems, heat exchangers, and high-performance cooling solutions. Easy to machine, it ensures efficiency and reliability in every technical application.

PROS

- Resistant to marine and industrial corrosion

- Very high conductivity (100% IACS)

- Good impact resistance

CONS

- Expensive

- Heavy

MAIN FEATURES

- Process: CNC Machining

- Tolerances: ISO 2768-1 fine (f) or medium (m) class. Info

- Max size: 300x300x45mm ; 12x12x1.8 in

- Lead time: <4 days

C101 COPPER CNC MACHINED VIDEO GALLERY

MARINE AND INDUSTRIAL CORROSION RESISTANCE

Copper C101 is known for its exceptional resistance to marine and industrial corrosion, making it an ideal choice for applications in aggressive environments such as coastal and industrial. Due to its high purity, this type of copper forms a protective patina that shields it from the corrosive effects of salt water and chemicals found in heavy industries.

HIGH ELECTRICAL CONDUCTIVITY

Another significant advantage of C101 copper is its high electrical conductivity, which reaches 100% IACS (International Annealed Copper Standard). This characteristic makes it essential in electrical and electronic applications, where efficiency in energy transmission is crucial. Its ability to carry electrical current without significant losses makes it indispensable in cables, conductors and electronic components.

IMPACT RESISTANCE

Copper also has good impact resistance, making it suitable for uses where mechanical strength is required. This impact resistance allows this material to maintain its structural integrity even when subjected to physical stress, making it a reliable choice for industrial and mechanical applications.

GALLERY

Realise your copper pieces now

Upload your 3D file to turn your project into reality

free instant quoteCOPPER C101 COMMENT

Copper is a material widely used in many industrial and consumer applications due to its exceptional electrical and thermal conductivity properties. One of its best-known variants is copper C101, a pure form of the metal known for its high ductility and impact resistance.

Pros

Corrosion resistance: C101 copper is characterised by its exceptional resistance to corrosion in both marine and industrial environments. Its ability to withstand the action of corrosive agents guarantees exceptional durability even in the most hostile conditions, lending reliability and longevity to its applications, both in the open sea and in aggressive industrial environments where exposure to corrosive substances is common. Thanks to this resistance, it establishes itself as a reliable and durable material, ideal for applications requiring long-lasting protection against corrosion and degradation.

High conductivity: The electrical conductivity of this copper alloy is unparalleled, reaching 100% of the International Annealed Copper Standard (IACS). This extraordinary conductivity makes it the ideal material for a wide range of electrical applications, where electrical conduction efficiency and accuracy are critical. From electrical infrastructure to consumer electronics, C101 copper offers superior performance, ensuring efficient and reliable energy transmission. Its excellent conductivity places it at the top of conducting materials, offering optimal performance in terms of energy transmission and distribution.

Good impact resistance: Despite its relative softness, it has surprising impact resistance, bringing durability and robustness to its applications. This characteristic is particularly important in environments subject to mechanical stress and accidental impacts, where protection and structural integrity are essential to ensure reliable performance over time. Thanks to its ability to withstand impact, it proves to be a versatile and reliable material, suitable for a wide range of industrial and consumer applications, where robustness and impact resistance are critical to project success.

Cons

Expensive: It is important to mention that this copper may cost more than other alternative materials. This is mainly due to its purity and the superior performance offered. However, it is crucial to consider that despite the higher initial cost, investments in copper often pay off over time due to its superior reliability, durability and performance. In many applications, the higher efficiency and reliability offered more than compensate for its initial cost, providing long-term value and reducing maintenance and replacement costs.

Heavy: The density of C101 copper makes it a relatively heavy material compared to other alternatives. This may limit its use in some applications where weight is a critical factor, such as applications that require lightweight components to ensure optimal energy efficiency or to facilitate transport and handling. However, it is important to consider that despite its relative heaviness, it offers a number of unique advantages that can compensate for this disadvantage in many situations. Its superior strength, durability and performance can make it preferable for use in contexts where weight is an important consideration, while ensuring uncompromising quality and reliability.

Applications

Electrical current distribution: It is widely used in electrical current distribution due to its excellent electrical conductivity. This characteristic makes it ideal for use in electrical wiring, printed circuit boards, electrical transformers and other electronic components where efficient and reliable transmission of electricity is required. Its low electrical resistivity allows for loss-free transmission of energy, ensuring optimal operation of electrical systems.

Heat exchangers: Due to its high thermal conductivity, copper alloy C101 is used in heat exchangers used in a wide range of industrial and domestic applications. These exchangers transfer heat from one fluid to another, enabling the cooling or heating of rooms, liquids or gases. Copper C101 offers excellent heat transfer efficiency, ensuring rapid heat dissipation and optimal operation of heating, air conditioning and refrigeration systems.

Cooling systems: In cooling systems, it is used in radiators, piping and other components essential for heat transfer and thermal dissipation. Its high thermal conductivity enables rapid dissipation of heat generated by engines, electronic circuits and other heat sources, keeping temperatures under control and preventing overheating. These cooling systems are essential in a wide range of industries, including automotive, electronics, manufacturing and aerospace, where maintaining optimal temperatures is crucial to the proper functioning of devices and equipment.

Conclusion

In conclusion, C101 copper emerges as a versatile and reliable material, widely used in many industrial and consumer applications. Its exceptional electrical properties, corrosion resistance and thermal conductivity make it an ideal choice for a wide range of applications, from electrical infrastructure to heat exchangers and cooling systems. Despite its higher initial cost compared to other materials and its relative heaviness, the advantages offered by this alloy in terms of reliability, durability and superior performance often justify the investment. With a demonstrated history of success and an ever-expanding range of applications, this material remains a reliable and durable choice for projects requiring uncompromising quality and performance.

MATERIAL PROPERTIES

| Tensile breaking load | 300 MPa |

| Modulus of elasticity | 115 GPa |

| Elongation at break | 35% |

| Density | 8,91 g/cm³ |

| Melting temperature | 1083 ºC |

| Izod impact resistance | 1,6 kJ/m² |

| Yield Strength | 250 MPa |

At Weerg, we pride ourselves on providing fast, reliable and amazing customer service. We believe that this is what distinguishes great companies from others.

Questions and answers

Copper is a reddish-orange metal known for its high electrical and thermal conductivity, second only to silver. It is a ductile and malleable material that can be shaped into various forms without losing its properties. Copper is also corrosion-resistant, thanks to its ability to form a protective patina, and has been used since ancient times in various fields, from electronics to construction.

Copper is not magnetic. It is a diamagnetic material, meaning it does not significantly react to external magnetic fields. This property distinguishes it from ferromagnetic materials like iron and steel. However, copper can be affected by magnetic fields through phenomena such as eddy currents, but it does not acquire intrinsic magnetic properties.

Copper is an extremely versatile material used in a wide range of applications due to its excellent conductive, mechanical, and corrosion-resistant properties. It is widely employed in the electrical and electronics sectors for cables, conductors, and electrical components. In the automotive industry, it is used in cooling systems, wiring, and mechanical components. Copper is also found in household appliances, plumbing systems, heat exchangers, and decorative items. Its thermal conductivity makes it ideal for heat sinks and pipelines.

Copper does not rust, as rusting is a process specific to iron and its derivatives. However, copper can oxidize, forming a protective layer on its surface, known as a patina, which is green or brown in color. This patina does not damage the material; instead, it further protects it from corrosion.

Copper has a relatively high density of about 8.96 g/cm³, making it heavier than common materials like aluminum or plastic but less heavy than metals such as lead. Its density makes it particularly suitable for applications requiring robust and stable materials.

Yes, copper is one of the best conductors of electricity. Due to its excellent electrical conductivity, it is widely used in the production of electrical cables, wires, and other electrical and electronic components. Its conductivity is second only to silver, but copper is more affordable and abundant, making it the preferred choice for electrical applications.

QUOTE IN 3 SECONDS WITHOUT COMMITMENT

Do you want to turn your 3D project into reality?

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quote