4 min read

Uses of Metals: Types, Classifications and Applications

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

The need to get reliable data from repeatable tests that can be used by designers for the material choice is the main reason why a number of standardized tests have developed over time to define materials.

One kind of test concerns impact tests. They want to determine whether a material has fragile or ductile behaviour and to what extent. The brittle type will have a clean break and it will absorb a limited amount of energy during failure, whereas a ductile material will deform both elastically and plastically, dissipating part of the impact energy.

Impact resistance is a property which is not a unique value for every material as it can differ considerably depending on the HDT of the object. It is therefore interesting to investigate the different behaviour of the material at different temperatures in order to construct a graph and understand the possible temperature ranges of use.

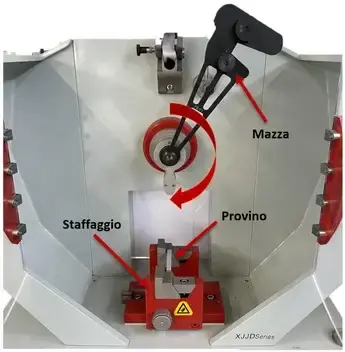

The tests are performed by a tool equipped with a calibrated mallet which impacts the specimen with a known amount of energy (proportional to the weight of the mallet and the starting height) when it rotates. The energy dissipated is measured by the angle at which the bat rises after impact; the greater the angle, the less energy is dissipated. In the picture below we can see the test machine in use in Weerg, ready to run the test on a PA12 specimen made in HP MJF 3D printing.

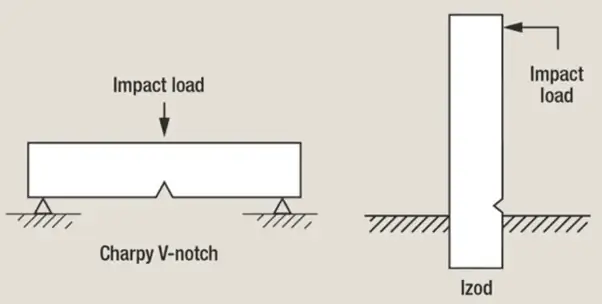

There are different approaches to performing these tests and the two most popular are:

Test Charpy - Standard ISO 179

Test Izod - Standard ISO 180

The following picture shows the two different configurations. In Weerg all tests are performed by the Charpy approach following the regulations, in order to have uniform and comparable data both between the different materials available in our portfolio and materials produced with other technologies. It also gives designers a clearer idea of the possible applications of the processed materials with additive technologies, which are increasingly replacing traditional production technologies.

If you still have doubts, questions or need additional information, our team of experts is available free of charge to support you in your choice: contact them to talk to them about your project and what doubts you have regarding the construction material.

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...