3 min read

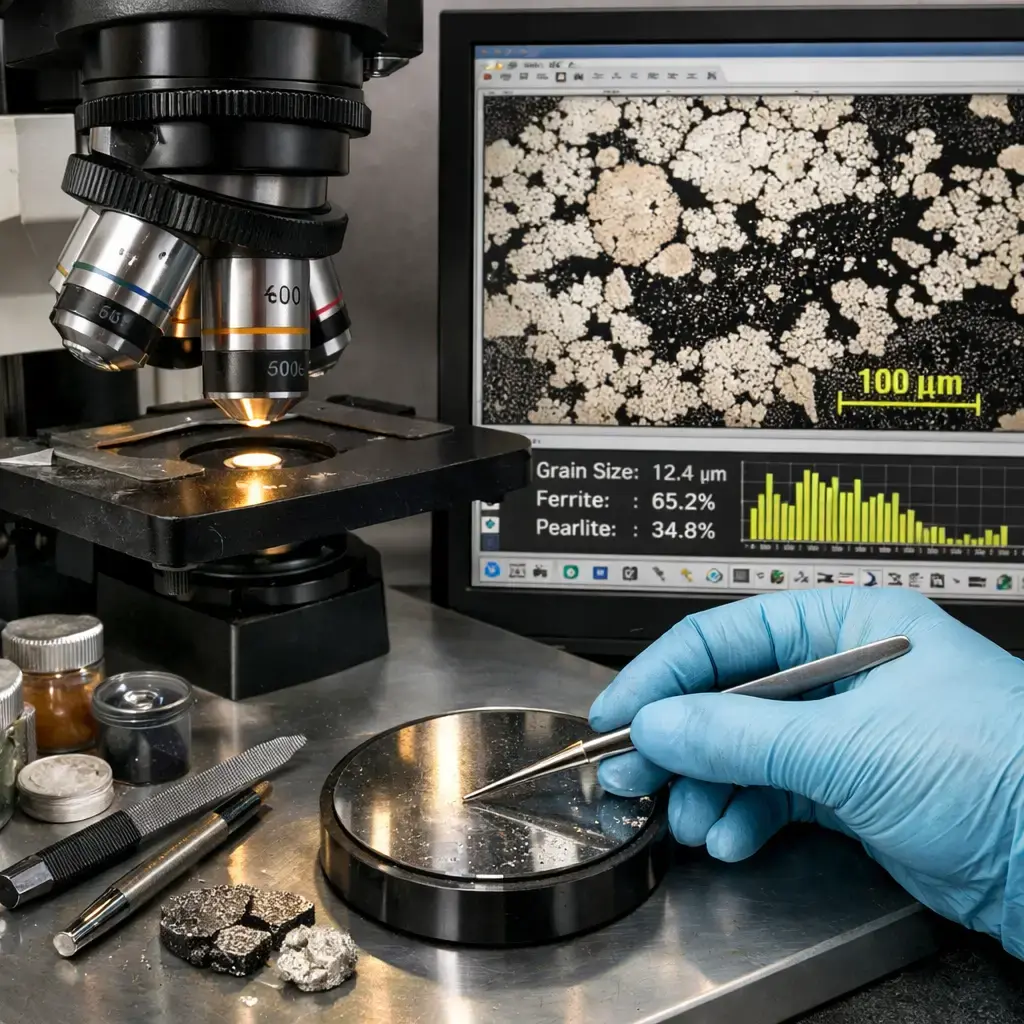

Metallographic Analysis: Microstructure and Quality Control

Metallographic analysis is a fundamental technique used to study the microstructure of metals and alloys. By observing a specially prepared sample...

4 min read

![]() Weerg staff

:

May 30, 2025

Weerg staff

:

May 30, 2025

3D printed glasses represent one of the most promising applications of additive manufacturing, combining customization, innovation and high performance. Among the technical materials used in 3D printing, Ultem emerges as one of the most attractive for advanced applications due to its unique characteristics of strength, light weight and dimensional stability.

Ultem 9085 is a high-performance thermoplastic polyetheretherimide (PEI) known for its exceptional thermal, chemical and mechanical resistance. It can withstand temperatures up to 186°C without losing its structural properties, making it suitable for extreme environments. It also shows great resistance to chemicals, including hydrocarbons, solvents, and industrial fluids.

This material also offers remarkable mechanical strength and stiffness, features that are ideal for applications where strength is a key requirement, such as in the case of eyewear used in industrial or sports settings.

3D printing with Ultem offers several technical advantages in eyewear production over traditional methods. First of all, it allows absolute geometric freedom, making it possible to produce highly customized frames ergonomically adapted to the specific needs of each user. This level of customization ensures superior comfort compared to glasses produced using traditional techniques, which are often less precise in terms of ergonomics.

Light weight is another strength of Ultem. Due to its low density, eyewear made from this material is particularly lightweight, significantly reducing fatigue during prolonged use. This benefit is especially appreciated in sports settings, where weight and comfort are essential.

Another distinctive technical aspect of Ultem molded glasses is their excellent dimensional stability. In fact, the material maintains its shape and mechanical properties over the long term, even under environmental stresses such as temperature variations, humidity and UV exposure. This ensures that the eyewear does not undergo premature deformation or deterioration, providing significantly longer life than conventional thermoplastic materials.

Ultem 1010 is certified for use in direct skin contact, meeting strict biocompatibility standards. This characteristic makes the material particularly suitable for eyeglasses, protective eyewear in the medical field, and personal devices used on a daily basis, minimising the risk of allergic reactions or skin irritation.

3D printed glasses with Ultem are widely used in various sectors. In industry, for example, frames made from this material offer robust and reliable protection against shocks and aggressive chemicals. In the sports sector, on the other hand, athletes can benefit from ultralight, impact-resistant frames suitable for high performance.

In the medical sector, Ultem enables the fabrication of highly customized frames for users with special needs, such as adaptations for specific anatomical conditions or therapeutic needs. The precision and customisation capabilities of 3D printing make the process ideal for creating customised eyewear, greatly enhancing the experience of users with special needs.

Sustainability is another important technical and environmental benefit of glasses produced by 3D printing in Ultem. Additive manufacturing significantly reduces waste compared to traditional processes, as material is used only where needed, limiting waste. In addition, the absence of the need for specific molds or equipment significantly lowers the environmental impact, contributing to a more responsible manufacturing process.

In eyewear production, material selection is a crucial choice, directly influencing not only the aesthetic appearance of the final product but also its mechanical strength, durability, comfort, and ability to adapt to the specific needs of users. In recent years, thanks to advances in 3D printing technology, innovative materials such as Ultem have gained prominence alongside traditional materials such as acetate, nylon and titanium.

Compared to cellulose acetate, a material historically popular in eyewear manufacturing due to its wide range of colors and aesthetic finishes, Ultem offers significantly superior mechanical and thermal resistance. Although acetate allows great aesthetic freedom, making it ideal for fashionable eyewear, it has some limitations in terms of impact resistance and thermal stability, as it tends to deform when exposed to heat sources for prolonged periods. In contrast, Ultem maintains dimensional and aesthetic stability even under unfavorable conditions, ensuring longevity and superior performance.

Compared to nylon, including its best-known variant TR-90, Ultem is generally stiffer, offering less flexibility but superior strength under thermal and chemical stress conditions. Nylon, due to its high elasticity and impact resistance, is widely used for sports and protective eyewear. However, in the long run it can show signs of deterioration from prolonged exposure to UV rays, losing some of its original mechanical properties. In contrast, Ultem retains its mechanical and chemical properties over time, making it an optimal choice for eyewear intended for applications where durability is a must.

When the comparison is extended to titanium, a lightweight and durable metal often associated with high-end eyewear, additional interesting considerations emerge. Titanium offers significant advantages in terms of light weight, corrosion resistance and hypoallergenicity, making it ideal for users sensitive to base metals. However, compared to 3D-printed Ultem, titanium has significantly higher processing costs and more significant design limitations, as the process of machining and finishing titanium is complex and requires specialised technologies. Ultem, on the other hand, thanks to 3D printing, allows significant simplification in the fabrication of complex and highly customised geometries, with lower costs and reduced production time compared to titanium.

Analysing the properties of these materials globally, it is clear that 3D printed Ultem is a highly competitive solution for those seeking a compromise between high technical performance, light weight, and customisation. The ability to precisely tailor frames to the ergonomic and functional specifications required by the end user, coupled with the material's outstanding thermal and chemical resistance, places Ultem in a prime position for advanced sport and industrial applications.

Ultimately, the choice of material depends strictly on the end application and the user's priorities. If the goal is a sophisticated and versatile frame design, acetate remains an excellent choice; for those who favor flexibility and impact resistance, nylon remains the ideal solution; those seeking absolute lightness and premium hypoallergenicity will inevitably turn to titanium. However, for applications where strength, durability and technical customisation are essential, 3D printed Ultem represents one of the most innovative and promising options in eyewear.

In conclusion, 3D printed glasses with Ultem represent an ideal meeting point between technological innovation, functionality and sustainability. Due to its outstanding technical characteristics, such as exceptional thermal and chemical resistance, light weight, dimensional stability and ergonomic customisation capabilities, this material offers unique advantages over traditional alternatives such as acetate, nylon and titanium. The use of additive manufacturing with Ultem also allows for reduced production waste and flexible adaptation to specific needs, thus contributing to a more sustainable and precision-oriented future. Ultimately, choosing 3D printed glasses made from Ultem means investing in an advanced, durable and highly customized product that is perfect for meeting the most demanding needs in the medical, industrial and sports sectors.

3 min read

Metallographic analysis is a fundamental technique used to study the microstructure of metals and alloys. By observing a specially prepared sample...

2 min read

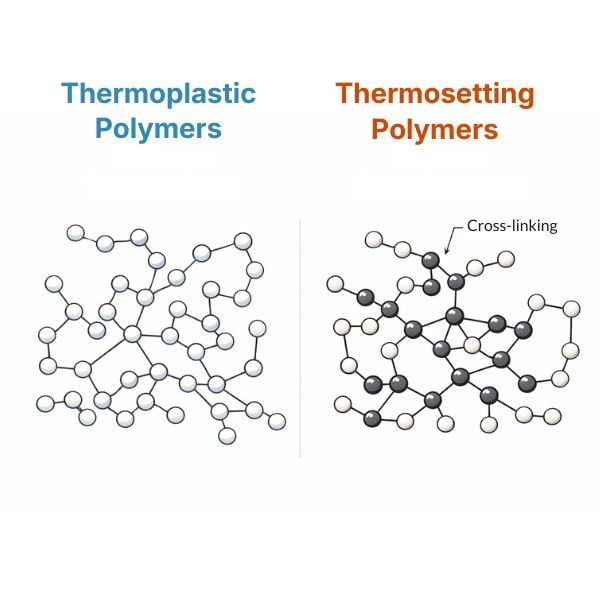

Polymers represent one of the most versatile families of materials in modern industry. Within this category, the fundamental distinction is between ...

3 min read

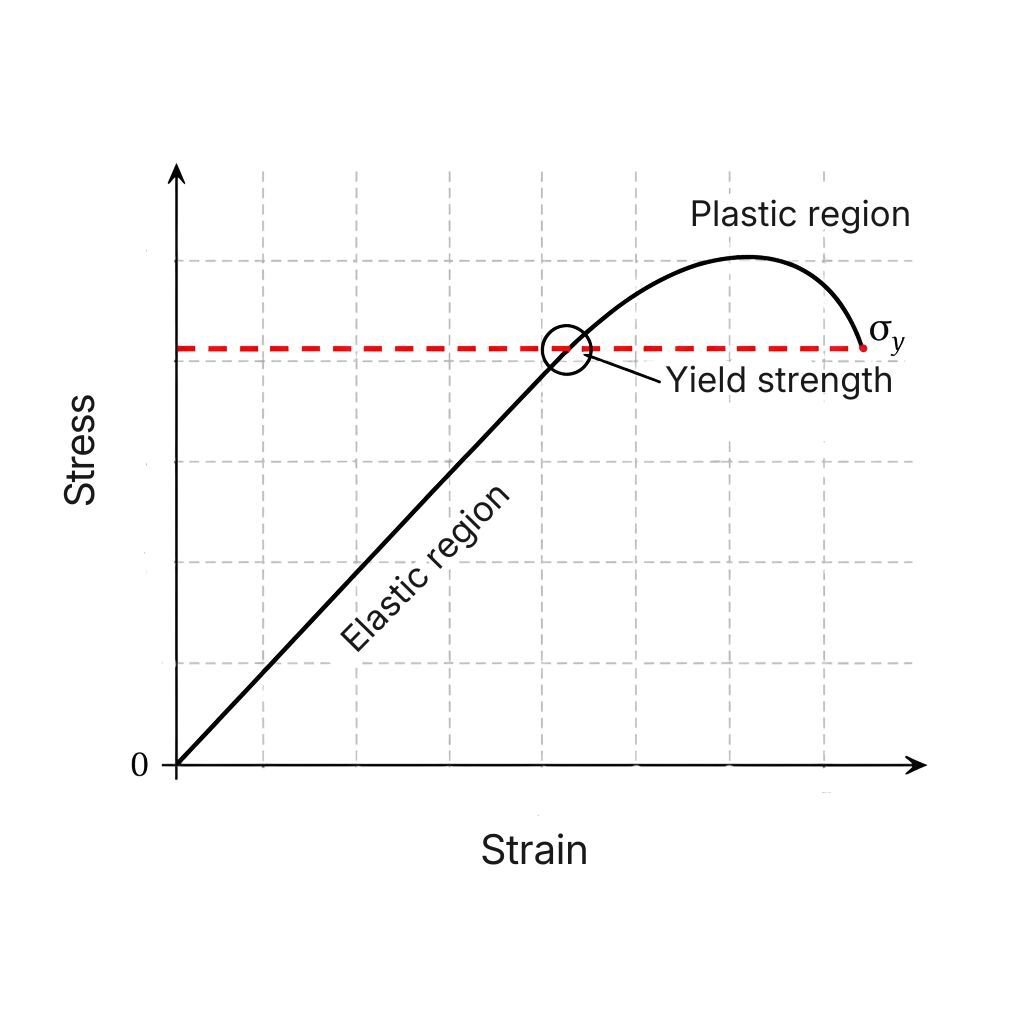

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...