2 min read

Thermoplastic and Thermosetting Polymers: Differences and Uses

Polymers represent one of the most versatile families of materials in modern industry. Within this category, the fundamental distinction is between ...

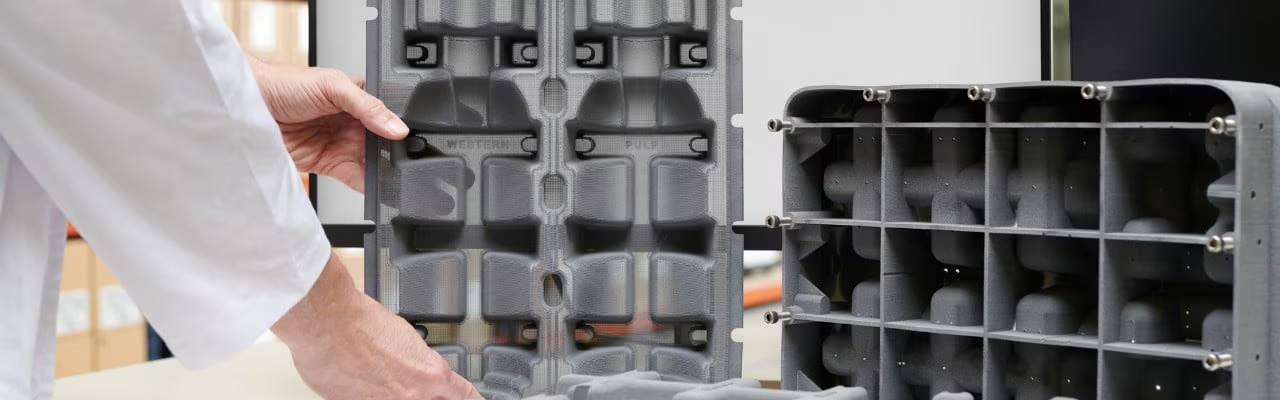

3D printing is a revolutionary technology that is rapidly transforming many industries, including the packaging industry. This sector has always been strategic, representing the direct interface between the product and the end consumer. Today, thanks to the integration of 3D printing, packaging is experiencing a new era characterized by high customization, greater sustainability, and incredibly fast development and prototyping.

One of the most obvious advantages of 3D printing applied to packaging is undoubtedly the ability to create complex, customized shapes with an ease and speed unthinkable with traditional methods. With 3D printing, it is possible to produce unique packaging that is perfectly adapted to the shape of the product, thus ensuring optimal protection while simultaneously providing distinctive and attractive aesthetics.

Companies operating in niche industries, such as luxury, gourmet food or cosmetics, are taking advantage of 3D printing to produce packaging that fully reflects brand values and responds to specific consumer needs. This level of customization not only strengthens the brand image, but also increases the perceived value of the product by the end customer.

3D printing has greatly simplified the prototyping process in packaging. Traditionally, developing new packaging required long design times, expensive molds, and numerous tests. Today, with additive technology, functional prototypes can be created in a matter of hours, making immediate changes and quickly verifying their effectiveness on the final product.

This not only drastically reduces the time required for new product development, but also saves money. Companies can thus experiment with multiple solutions simultaneously, choosing the optimal one with greater ease and lower initial investment.

3D printing offers a wide range of innovative materials that provide high performance and specific characteristics suitable for different applications in packaging. One of the most widely used materials is nylon PA12, printed with advanced technologies such as Multi Jet Fusion (MJF). This material is prized for its mechanical strength, light weight and flexibility, characteristics that are ideal for packaging requiring impact protection and extended durability. Due to its dimensional stability and resistance to chemicals, nylon PA12 is particularly effective for packaging intended for sensitive sectors such as the pharmaceutical, food and cosmetics industries. In addition, this material allows for high-quality surface finishes, a crucial element for those packaging where aesthetics and functionality must be perfectly integrated.

Another widely used material in 3D printing applied to packaging is ABS (Acrylonitrile Butadiene Styrene), known for its strength and versatility. ABS offers excellent resistance to impact and high temperatures, making it ideal for protective packaging that is resistant to adverse environmental conditions. Its ease of processing and the good surface finish that can be achieved make this material an excellent choice for companies that want durable and functional packaging.

Ecotech, on the other hand, represents an innovative solution geared toward environmental sustainability. This material is composed in part of recycled polymers, a feature that significantly reduces its ecological impact. In addition to being an eco-friendly choice, Ecotech maintains good mechanical properties and a good aesthetic finish, enabling companies to effectively and practically meet the growing demand for sustainable products from modern consumers.

The combined use of these advanced materials thus enables companies to create highly customized, high-performance packaging, meeting specific requirements for protection, aesthetics, and sustainability, which are essential to remain competitive and meet the increasingly sophisticated needs of the market.

Sustainability is now a key priority for consumers and companies, and packaging is no exception. 3D printing offers the ability to create packaging using biodegradable and recyclable materials, significantly reducing environmental impact compared to traditional materials such as single-use plastics and complex packaging that are difficult to dispose of.

The use of environmentally friendly materials allows not only a reduction in waste, but also greater consistency with circular economy principles, where waste can be reused or reintegrated into the production cycle.

3D printing is increasingly finding concrete applications in packaging, with significant examples in several industries. In the cosmetics industry, prestigious brands are already leveraging additive technology to create highly customized packaging that perfectly reflects the identity and exclusivity of their products. Companies such as L'Oréal and Chanel are using 3D printing to produce innovative and distinctive packaging that further enhances brand perception.

In Food & Beverage, 3D printing enables the creation of customized packaging for niche products, such as gourmet foods and artisanal beverages. This type of packaging is essential for communicating product quality, originality and craftsmanship, adding perceived value and enhancing the consumer shopping experience.

Image by HP

The pharmaceutical and healthcare industries are also benefiting from the precision and customization offered by 3D printing, making specialized containers for delicate medicines or medical devices that need advanced and specific protection. These 3D printed containers ensure maximum security and integrity of the contents, significantly improving the functionality of the packaging.

Despite its many advantages, 3D printing applied to packaging faces some major challenges that still limit its large-scale adoption. One of the main challenges is production scalability: currently, 3D technology is mainly ideal for limited production, prototypes or small custom runs. For mass production, in fact, it may be less economical and competitive than traditional methods, which benefit from more significant economies of scale.

Another critical issue concerns cost and material availability. Although there are innovative and sustainable materials suitable for 3D printing, these often have higher costs than traditional options, making the choice economically challenging for companies, especially in highly competitive or cost-sensitive settings.

Finally, an additional challenge is surface quality and the need for additional finishes to meet very high aesthetic standards, especially in demanding industries such as luxury and cosmetics. In these cases, 3D printing must often be combined with additional post-production processing to achieve the desired aesthetic result, thus increasing the complexity and overall cost of the production process.

The future of 3D printed packaging looks promising and full of opportunities. As technology continues to develop, production costs are expected to decrease even further, making this technology even more accessible and affordable even for large production runs. The evolution of sustainable and high-performance materials will allow current limitations to be overcome, further increasing the adoption of 3D printing in multiple industries.

In conclusion, the integration of 3D printing in packaging represents a disruptive innovation capable of revolutionizing the entire industry, bringing benefits in terms of customisation, speed of development and environmental sustainability.

2 min read

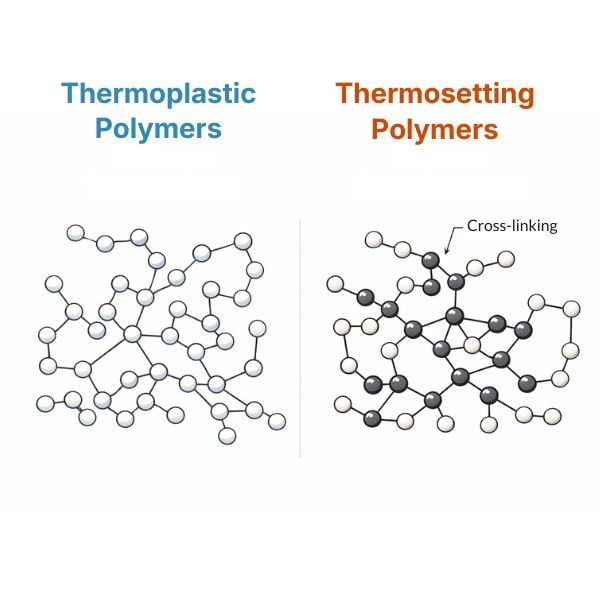

Polymers represent one of the most versatile families of materials in modern industry. Within this category, the fundamental distinction is between ...

3 min read

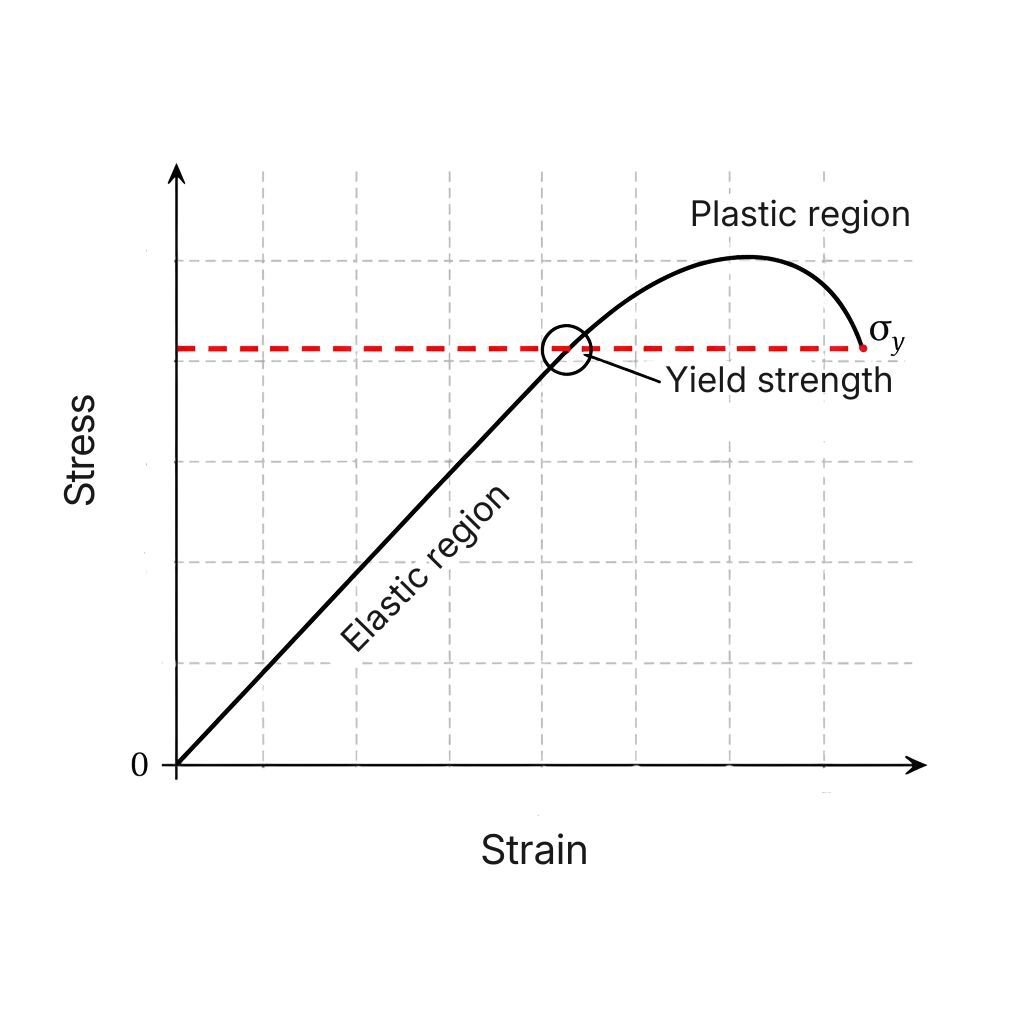

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...