| High temp pro Resin | ABS Like pro Resin | Best Price Classic Resin | Tough PP-like Resin | Ceramic | Versatile w135 Resin | Flame Retardant Resin | |

|---|---|---|---|---|---|---|---|

| Properties | |||||||

| Tensile breaking load | 75 MPa | 53 MPa | 31 MPa | 35 MPa | 76 MPa | 69 MPa | 74 MPa |

| Modulus of elasticity | 3,2 GPa | 1,8 GPa | 0,8 GPa | 1,3 GPa | 10 GPa | 2,9 GPa | 3,9 GPa |

| Elongation at break | 3 % | 43 % | 6,7 % | 100 % | 1 % | 8 % | 3 % |

| Flexural modulus | 3168 | 1780 | 700 | 1300 | 8780 | ||

| HDT 0.45 MPa | 238 °C | 63 °C | 68 °C | 52.8 °C | 280 °C | °C | °C |

| Izod impact resistance | 14.6 kJ/m2 | 53 kJ/m2 | 27 kJ/m2 | 62 kJ/m2 | 2,4 kJ/m2 | kJ/m2 | kJ/m2 |

| Features | |||||||

| Price range | € € € € € | € € € € € | € € € € € | € € € € € | € € € € € | € € € € € | € € € € € |

| Lead time | <2 days | <2 days | <2 days | <2 days | <2 days | <2 days | <2 days |

| Quote | Quote | Quote | Quote | Quote | Quote | Quote | |

Resin 3D printing

Detail, smooth surfaces, mechanical properties: find the perfect balance with our selection of 6 different resins.

6 different resins 3D printed, each with its own unique characteristics and advantages

"Resin 3D printing has allowed us to be more creative and efficient in our designs, resulting in faster product development cycles and improved outcomes."

compare the properties

"The high degree of accuracy and detail achieved with resin 3D printing has enabled us to create products of unparalleled quality and performance."

QUOTE IN 1 SECOND WITHOUT COMMITMENT

turn your 3D resin projects into reality

Upload your 3D file to get one step closer to manufacturing your parts.

free instant quoteWhat is resin 3D printing

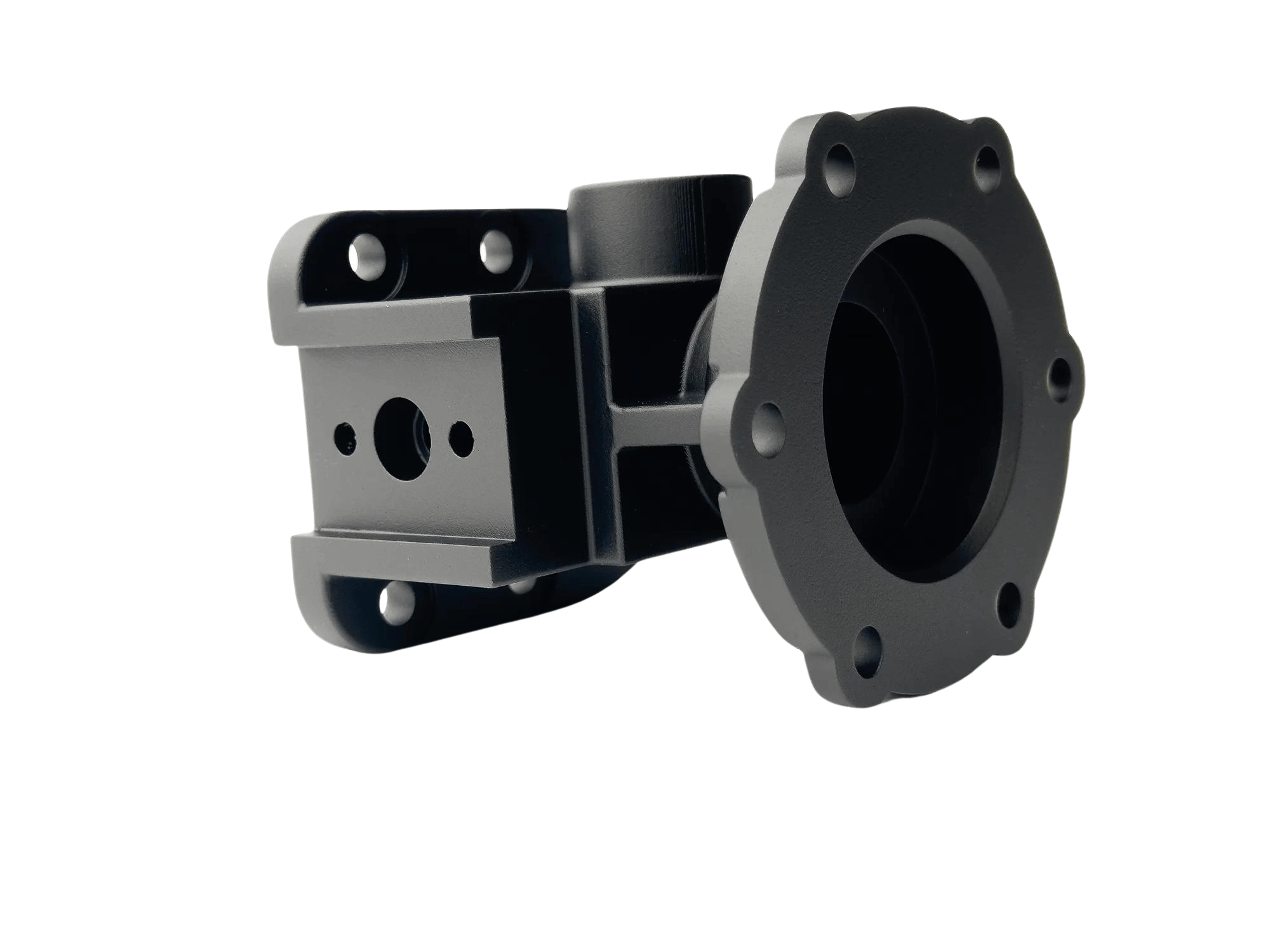

Resin 3D printing represents an advanced technology that has revolutionised the field of prototyping and three-dimensional object production. The resin used in this context is a liquid material that polymerizes under the influence of ultraviolet light, making it a key component in resin 3D printers. This process, known as photopolymerization, enables the creation of detailed and complex objects with extraordinary precision, showcasing the unique characteristics of resin for 3D printing.

Resin 3D printers operate through a layered process, where thin layers of liquid resin are solidified on top of each other to gradually build the desired object. This methodology offers significant advantages in terms of precision and detail compared to other 3D printing technologies, showcasing the versatility of 3D resins.

The available 3D resins for these printers cover a wide range of properties and applications, allowing the creation of objects with specific features such as transparency, flexibility, or thermal resistance. Resins for 3D printing contribute to the characteristics of resin 3D prints, offering a various range of material options.

Thanks to the flexibility offered by resin 3D printing, it becomes possible to produce objects with complex geometries and detailed supports that would be challenging, if not impossible, to achieve with other manufacturing methods. Resin 3D printing supports are particularly crucial in supporting structures during the printing process, ensuring the correct formation of every detail of the object.

The advantages of resin 3D printed parts are numerous and range from the quality of the print to the versatility of the material used. Firstly, it provides the best resolution, precision, and sharp details compared to other available 3D printing technologies on the market. Resin-printed parts have smoother surface finishes, providing a high-quality end result. However, it is important to note that the process may require post-production to remove the supports, ensuring a perfect finish of the object.

Professionals appreciate the ability of resin 3D printers to produce parts with fine details and smooth surfaces, ensuring the highest level of precision and accuracy. The stereolithographic technology used in resin 3D printing enables the production of isotropic, waterproof and mechanically versatile parts. Isotropy is a significant benefit as resin 3D printers create parts with similar properties on all axes. Additionally, the waterproof property of objects is valuable for sectors like engineering and manufacturing, where accurate control of air or fluid flow is essential. Resin 3D printing enables the creation of unique pieces, including those with solid parts or internal channels, facilitating control and prediction of fluid or air flow. Precision and tolerance are additional strengths of online resin 3D printing. The combination of controlled parameters, such as production temperature and resin quality, ensures precise results with higher tolerance compared to other 3D printing technologies. The repeatability of the process is guaranteed by a heated resin reservoir and an enclosed build environment, ensuring the production of identical parts. Finally, the versatility of the resins used in 3D printing allows parts with a wide range of properties to be created. Resins can be adapted to achieve specific characteristics, such as softness or hardness, and can be enriched with materials like glass or ceramics. This flexibility allows materials to be customised to the specific needs of each application, offering innovative solutions.

Types of Resins for Online Resin 3D Printing

The production of different resins through 3D printing technology has revolutionised the field of prototyping and the creation of three-dimensional objects. 3D printing resins offer a diverse range of materials, each with unique characteristics and distinct advantages. In this context, we will explore some of the most relevant resins, such as Tough PP-Like, High Temperature Pro 238°C, Ceramic resin, Best Price Classic, ABS Like Pro, and Versatile W135, analysing their peculiarities and specific applications where they excel.

Tough PP-Like Resin

By closely simulating the mechanical properties of polypropylene, Tough PP-Like resin offers durability, impact resistance, low water absorption and precision in resin 3D printers. It is particularly suitable for applications requiring a balance between rigidity and flexibility.

High Temperature Pro 238°C resin

High Temperature Pro 238°C resin is designed to withstand high temperatures, ensuring dimensional stability and a smooth surface. Suitable for molds and with excellent thermal characteristics, it represents an ideal option for many applications.

Ceramic Resin

The innovative Ceramic resin offers a ceramic-like appearance, thermal resistance, and a high elastic modulus. Despite its high density, it is the perfect choice for applications that require a unique aesthetic finish and thermal resistance.

Best Price Classic Resin

Best Price Classic resin offers a perfect balance between quality, resolution, and price, making it ideal for general use. With high resolution and a smooth surface, it is a reliable choice for a wide range of projects.

ABS Like Pro Resin

ABS Like Pro resin features a smooth surface, high detail level, and impact resistance. With isotropic properties, it is suitable for applications at both high and low temperatures, offering good mechanical performance.

Versatile W135 Resin

Versatile W135 resin offers excellent isotropy, long-term stability, and an optimal balance between mechanical and thermal properties. Its versatility makes it suitable for a wide range of sectors, ensuring reliability and durability over time.

Flame retardant resin

Flame Retardant (FR) resin emerges as a preferred choice in MSLA technology due to its flame resistance and self-extinguishing capability, offering unparalleled protection against fire. Its V-0 classification in flame resistance tests guarantees a maximum degree of safety, making it ideal for applications requiring reliability in emergency situations.

Weerg's Advantages for 3D Resin Printing

Weerg offers an excellent online 3D resin printing service, enabling customers to realise their designs with precision and versatility. Using MSLA (Mask Stereolithography Apparatus) technology with LSPC, Weerg guarantees high-quality results and efficient production times. The main benefit of this technology is the polymerisation of a complete layer using a matrix of ultraviolet (UV) LEDs and an LCD screen simultaneously, ensuring fast and detailed production. This process offers key advantages such as speed, high resolution and cost-efficiency, making it ideal for prototyping and production of detailed parts.

Weerg's MSLA technology has made 3D resin printing accessible online, allowing customers to benefit from high-quality finishes. For Basic finishing, Weerg removes the print media and applies light sanding, keeping the removal points visible. This option is recommended for functional components, parts not visible after assembly and prototypes. For a more advanced finish, the Professional, Weerg smoothes the surface making it perfectly even, eliminating the visibility of media removal points. This finish is recommended for model making, visible components and parts that will be handled.

Weerg, with its expertise in online 3D resin printing, offers a complete solution for projects requiring precision, detail and quality in resin prints, contributing to the development of innovative and customised projects.

Quote now your resin parts

Upload your 3D file to turn your projects into reality.

free instant quote