3 min read

CBAM Regulation: What It Is, How It Works and Weerg Compliance

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

The advent of FDM 3D printing technology (an acronym for Fused Deposition Modeling) has rapidly attracted an ever-increasing curiosity, both from the industry and the community of makers and hobbyists.

To attract attention to this technology, it was the possibility of creating a model or a prototype directly from a CAD file and, in relation to the chosen material, with greater or lesser simplicity of implementation.

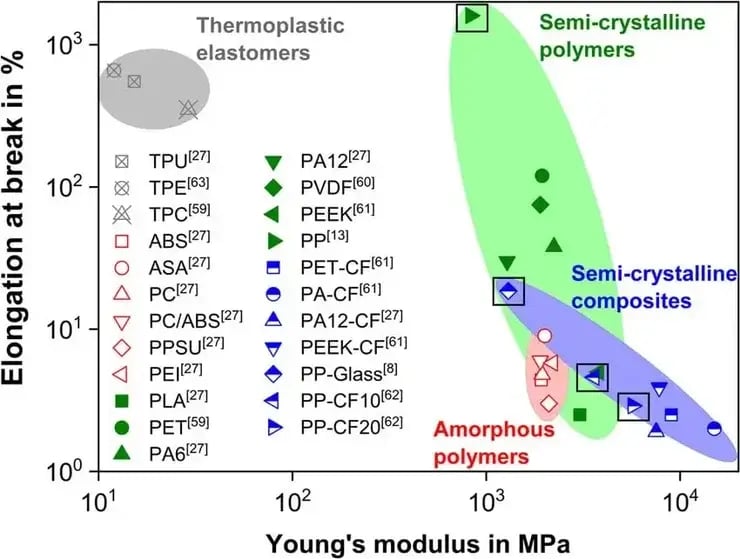

The material itself represents an important design component, given that different materials lead the same design to considerable differences in performance.

This guide is intended to help you identify the best FDM 3D Printing material for your project.

To date, the selection of materials from which you can choose to create your FDM 3D Printing project is very vast. Often they are divided by purpose of use, also in relation to the very different €/kg cost between the various families.

So let's start by dividing 3 important macro areas of use:

The filaments that can be processed by all the low cost 3D printers that are now on the market fall into the consumer category. They are easy to print and being the most popular, they have a huge variety of colors, finishes and variants "loaded" with different fillers. On the other hand, they have medium-low mechanical properties that limit their possible applications and resistance to low temperatures (below 60 ° C) that restrict their field of use.

PLA is by far the most popular polymer for FDM 3D printing due to its extreme ease of processing due to the low extrusion temperatures and the lack of the need to use a heated print bed, as well as the cost per kg very low. However, it is severely limited by the maximum use temperature of about 40°C - 50°C. Beyond this value there is an evident softening of the component which therefore loses its geometric characteristics. A classic example for realizing the temperature range we are talking about is the interior of a car parked in the sun.

The filaments based on PLA are part of this nomenclature, to which additives and fillers are added to improve some aspects of aesthetic performance or mechanical and thermal resistance. Unfortunately, having as a base a polymer with low properties, they are better in some aspects but do not differ much from the base polymer.

The use of PVB in FDM 3D printing arises from the need and desire to overcome the technological limitations of this process that produces components with a relatively rough finish. In fact, PVB allows it to be post-treated by immersing the component in a bath of solvent vapors which, attacking the surface of the piece, redistributes the material, smoothing it. It is possible to obtain objects with glossy finishes and similar to the components produced by injection. On the other hand, the mechanical and thermal properties of this material are scarce and limit its possible uses.

In recent years, PETG is establishing itself as an optimal choice to have an ease of printing similar to PLA, although with some more problems regarding the management of shrinkages and dictated by the need for a heated printing bed, while offering better thermal and mechanical properties

When consumer materials are unable to meet the needs of the project designer, it is necessary to turn to more performing materials, but which result in more stringent printability requirements. It may therefore be necessary to use a printer with a closed chamber or with the ability to reach higher temperatures. In addition, the heated print bed becomes an essential necessity.

ABS was the standard material used by all printers during the development period of the RepRap project and then discarded due to printing difficulties.

It has good mechanical properties, showing ductile behaviour and resistance to temperatures up to 90 ° C. It allows it to be smoothed by chemical polishing thanks to the action of acetone which dissolves and redistributes the material on the surface.

PC is excellent heat resistance and good mechanical properties make it a material used for the creation of tools, fixtures and final parts in various sectors including the automotive sector. It is a rigid polymer and can also be found free of dyes in a transparent version thanks to its excellent optical properties.

PC-ABS is a mix of two different polymers, it has a combination of the good properties of both, with excellent ductility, good resistance to temperatures and at the same time facilitates printing by decreasing the deformations that may arise during the construction of the components.

Flexible materials have a very high elongation at break as well as a low elastic modulus. They are characterized by excellent adhesion between the layers and excellent resistance to abrasion and wear. However, they require ad-hoc extrusion systems to properly manage the flexible wire which, during printing, tends to compress and stretch in the section that precedes the nozzle.

Polypropylene is often used for food or skin contact applications, it has good chemical resistance and stability, as well as low density. Processed using FDM technology, it has a behaviour very close to isotropy (mechanical strength equal in all directions) thanks to excellent adhesion between the layers. However, complex structures are very difficult to create, as the supports of the same material are very difficult to manage and remove, furthermore, the chemical stability of the material makes it not very similar to soluble supports.

Finally, we come to high-performance industrial materials. They possess incredible properties that challenge and in some cases surpass those of some metals such as aluminium. However, they require very high process temperatures such as nozzle above 400 ° C, flat at 130 ° C and printing chamber closed and heated up to 90 ° C. Therefore, industrial machinery capable of reaching those temperatures and guaranteeing the repeatability of the process conditions are required to obtain satisfactory results.

Nylon PA12 of the polyamide family, has an exceptional mix of good mechanical properties, with good tensile strength and excellent toughness combined with good elasticity and ductility. It also has good resistance to temperatures up to over 120°C. Finally, it has excellent resistance to wear and rubbing. However, it is difficult to process correctly both for its hygroscopicity (absorption of moisture from the air) and for shrinkage during printing which can lead to deformation and detachment from the construction platform.

Starting from the excellent base of PA12, adding short carbon fiber as a filler further improves the mechanical and thermal resistance to the detriment only of the impact resistance which decreases slightly. The elastic modulus increases considerably and is more than five times that of the PA12. This results in very strong and rigid components. The excellent chemical resistance to solvents and hydrocarbons also remains. The addition of carbon fiber also helps during the printing process as it stabilizes deformations and reduces them.

PEEK is a semi-crystalline polymer from the polyaryletherketone family and is one of the best performing polymers available in filament form for additive manufacturing. It has specific properties equal to or better than some non-ferrous metal alloys such as aluminium, such as a tensile strength of about 100 MPa. The downside is that it is a difficult material to manage as it is highly hygroscopic and requires very high process temperatures. In addition, the components detached from the build platform are amber in color and are amorphous, therefore their internal molecules are arranged irregularly. It is possible to proceed with a complex heat treatment to obtain the component in a semi-crystalline state, easily recognizable by the skin color it assumes. Although the mechanical and chemical properties of the material improve, the thermal treatment decreases the ductility and impact resistance. It therefore depends on the final application whether one or the other state is better.

As for the variant with the addition of PA12, even PEEK, if added with short carbon fiber, improves its mechanical properties and resistance to temperatures at the expense of impact resistance. The deflection temperature rises to over 310°C and the elastic modulus doubles. All these factors lead to higher processability both during the printing process and during subsequent heat treatments

In its two variants Ultem1010 and Ultem9085 it is used in the aerospace, medical, automotive, railways and military applications thanks to FST (Fire Smoke Toxicity) certifications. It has great resistance to high temperatures and is a great flame retardant. Unfortunately, it is even more complex to print than PEEK due to the even higher processing temperature requirements.

The support materials make it possible to create components with geometric characteristics that are impossible to produce without the use of support structures, while allowing easy removal, often by dissolution of the same.

PVA and BVOH are totally soluble in water and are compatible with a wide variety of materials.

HIPS is a "break-away" support, which facilitates its removal in components made of ABS, ASA, PC etc. It can be dissolved but only using a solvent called limonene.

PLA for its ease of printing, wide range of finishes available and low cost, remains the material of choice for many conceptual prototypes by the community maker. It allows you to have the first copies in a short time to realize the dimensions and geometries of the components and to test the dimensions / assemblies. However, it suffers from very low mechanical and thermal properties.

Nylon PA12 with the addition of carbon fiber is established as an excellent solution both for functional prototypes and for final components given the excellent thermal and mechanical properties and the possibility of having an interesting finish through post-processing. While limited on occasion by the higher cost and printing requirements, it is an excellent choice for a large number of applications.

At Weerg we process this material with the best online prices: upload your file, for an instant and free quote.

If printing requirements and cost are not a problem and the application requires its properties, PEEK is an almost obligatory choice to have the design freedom offered by additive manufacturing in combination with a polymer that has even higher properties of some non-ferrous alloys. It is certainly the choice for high-performance functional prototypes with heavy use in demanding environments from both a thermal and chemical point of view.

At Weerg we process this material with the best online prices: upload your file here, for an instant and free quote.

The choice of the correct material is a real phase of the project design; in fact, based on the design needs, the work environment and the stressful situations of the piece, it will be necessary to consider the right compromise offered by the current selection of materials that can be made with FDM technology.

Below, you can find the main factors to consider when choosing the material:

Mechanical strength - is the easiest property to understand and which first narrows the choice of material for our prototype. It is a good idea to have a safety factor and not merely use the maximum value of the load that our component will have to withstand, it is also true that choosing a high-performance material for making a static object for no reason would only raise costs;

Temperature of use (HDT - CUT) - The HDT or Heat Deflection Temperature, indicate the temperature at which a specimen subjected to a load of flexes and deforms in a plastic way, while the CUT or Continuous Use Temperature, indicates the temperature at which the material it can work continuously for an indefinite time. Both these data are crucial for the choice of the material as often the mechanical resistance is a function of the temperature of use;

Printability - inevitably the printing requirements of both temperature and size limit the choice to materials that can be processed correctly with the chosen 3D printer. They are not to be underestimated because maybe you can print "something" but for certain and repeatable results, more stringent requirements are necessary;

Finishing - in case there is a need for a good aesthetic result (company presentations or at the fair) it will be necessary to evaluate whether the chosen material can be treated with surface finishes and of what type: some materials, perhaps very performing in FDM 3D printing, do not have a pleasant aesthetic output;

Cost - Last, but not least, the cost also plays a role in this decision-making process as in all things, limiting the possibilities of choice for the realization of components.

To conclude, we have seen that there is no absolute best material, but every project requires the correct choice of the right support.

Let's keep these rules in mind to choose the best material for our FDM 3D Printing project:

If you have now found the best material for your project, you can make a cost estimate on your file.

If you still have doubts, don't worry: as you have seen, the choice of material is one of the most delicate design phases. Our team of experts is available free of charge to support you in your choice: contact them here to tell them about your project and what doubts you have regarding the construction material.

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

3 min read

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

3 min read

How Environmental Management System certification strengthens the quality of our production processes and the value we deliver to our partners