4 min read

Uses of Metals: Types, Classifications and Applications

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

![]() Weerg staff

:

Jul 13, 2021

Weerg staff

:

Jul 13, 2021

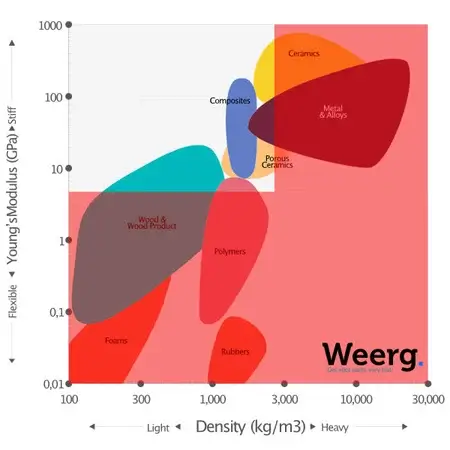

With their simplicity, Ashby's maps are an excellent support for a reasoned choice of the material with which to make your parts.

Let’s consider a design problem in which you are asked for a light and rigid component at the same time (for example the frame of a normal citybike).

Let’s start with the map “Young’s modulus” / “Density” and draw 2 lines that allow us to highlight only the materials that correspond to our needs:

1. Young’s modulus values for polymers are low (have low rigidity), therefore most polymers seem to be unusable.

2. Some metals, ceramics and woods can be taken into consideration, so composites apparently seem the best solution.

But let’s say right away that it is unlikely that the analysis of only 2 properties is sufficient for the choice of a material, therefore: what other properties is it important to compare before choosing?

So let’s consider a second map that relates “toughness” and “cost”.

1. The toughness of the ceramic is sufficient only for the compression load – but it is insufficient both in tension and in flexion.

2. Wood is not tough enough while composites may be too expensive.

3. We can safely conclude that the metals seem to give the general performance

Once we have identified a promising class of materials (in this case metals), we have to decide which members of this class are the best.

So we have to ask ourselves: which metal?

Selection tables can be used to select among members of a particular class by populating with the main materials.

For example in this case we can do this for metals in the stiffness-density graph.

Given their high strength and relatively low cost, we can say that steel could represent the best solution.1. Some metals look very good for lightness and rigidity such as magnesium, aluminum, titanium, while others are clearly eliminated – for example lead.

2. Steels are heavy, but also very rigid. So what metal do we choose?

We summarize what we have learned to know about the selection of materials.

• By comparing two (or even more) maps, the properties needed to meet the main design requirements can be quickly assessed.

• Charts can be used to identify the best classes of materials, and then to look in more detail within these classes.

There are many other factors yet to be considered, in particular the manufacturing methods, the thickness and shape of the component, the tolerances and more. We say that the selection made by the graphs must be left wide enough to keep a sufficient number of options open.

Ultimately, a good way to deal with the problem is to use the tables to quickly eliminate materials that are certainly not going well and possibly to quickly build a prototype rather than trying to identify the best single material too early in the design process.

Our design specification clearly said “normal city bike” otherwise it would have been easy to be tempted by wood as in this beautiful Selva.

Sources and further reading

Material selection from Wikipedia, the free encyclopedia https://en.wikipedia.org/wiki/Material_selection

Materials Selection for Mechanical Design.

Ashby Map for Stiffness-based and Strength-based Design: youtube video here

What is a Material Property Chart?

https://grantadesign.com/education/students/charts/

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...