4 min read

Uses of Metals: Types, Classifications and Applications

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

The lathe is one of the oldest and most essential machine tools in engineering.

From the hand-operated lathes of thousands of years ago to today’s high-precision CNC models, this machine remains indispensable for producing metal and plastic components with cylindrical or rotational symmetry.

This guide explains clearly and comprehensively what a lathe is, what turning involves, how it works, which operations it enables and the industries in which it is used.

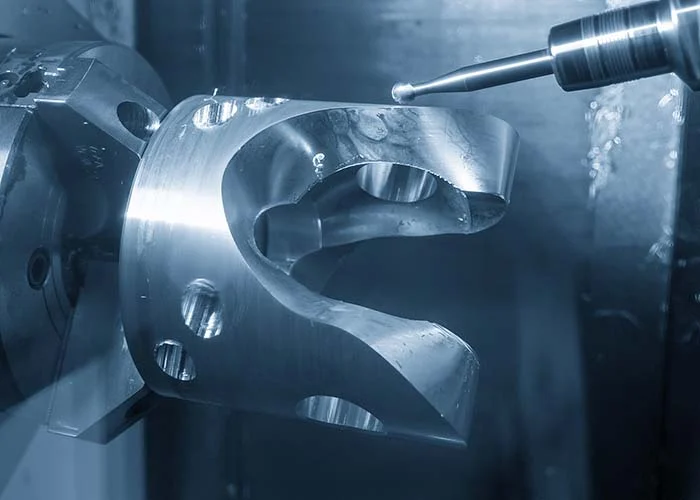

A lathe is a machine tool that works a part by rotating it while a cutting tool removes excess material.

The workpiece is clamped in the chuck and set in rotation; the tool, moving along one or more axes, shapes the final geometry.

It is the ideal machine for producing cylinders, cones, bushes, shafts, pins, nuts, threads and curved surfaces with very tight tolerances.

Turning is the machining process carried out on the lathe.

It is a chip-removal process in which:

Turning allows you to create:

external cylindrical surfaces

internal surfaces (boring)

tapers, chamfers and radii

grooves and recesses

internal and external threads

parting-off and end finishing

It is one of the most precise and repeatable processes in modern engineering and forms the basis of much of the metalworking industry.

The lathe is extremely versatile and enables many different operations:

✔ External turning

To create cylinders, tapers and curved surfaces.

✔ Internal turning (boring)

To produce accurate cavities, holes and seats.

✔ Threading

Internal or external threads (screws, studs, nuts).

✔ Parting-off

Separating and finishing ends.

✔ Chamfers and edge finishing

To remove sharp edges and improve appearance.

✔ Combined operations (advanced CNC lathes)

With driven tools, it is also possible to mill, drill and complete the component in a single setup.

Every lathe, from the simplest to the most advanced, includes several key elements:

Chuck → clamps and rotates the workpiece

Tailstock → supports long parts

Carriage → moves the tool along the axes

Tool turret → holds the tools

Bed → the supporting structure

Cutting tool → removes material

First threading lathe

There are various types, each designed for specific needs:

Centre lathe (manual)

The classic traditional lathe.

CNC lathe

Computer-controlled for high precision and series production.

Vertical lathe

Vertical spindle: ideal for very heavy or large-diameter parts.

Sliding-head (Swiss-type) lathes

Perfect for small precision parts and very long, slender components.

Multitasking lathes

Can also mill and drill thanks to powered tools.

A lathe can work a wide range of materials:

steel

stainless steel

aluminium

brass

copper

titanium

wood

composites

green ceramics

Because it offers:

precision

repeatability

operational versatility

production efficiency

excellent surface finish

It remains one of the most widely used machine tools in workshops and production lines.

Virtually everywhere:

general engineering

automotive and motorsport

aerospace

oil & gas

energy

medical

robotics

precision manufacturing

small metal parts

Any component with rotational symmetry is almost always produced on a lathe.

Modern CNC lathes offer:

full automation

micrometric precision

consistent quality

reduced waste

multitasking capability (milling + turning)

continuous production, even in series

They are essential for high-volume industrial production and complex parts.

The lathe and turning are fundamental pillars of precision engineering.

From artisan workshops to cutting-edge production departments, this technology enables the creation of accurate, functional and repeatable components.

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...