4 min read

Uses of Metals: Types, Classifications and Applications

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

3 min read

![]() Weerg staff

:

Oct 15, 2025

Weerg staff

:

Oct 15, 2025

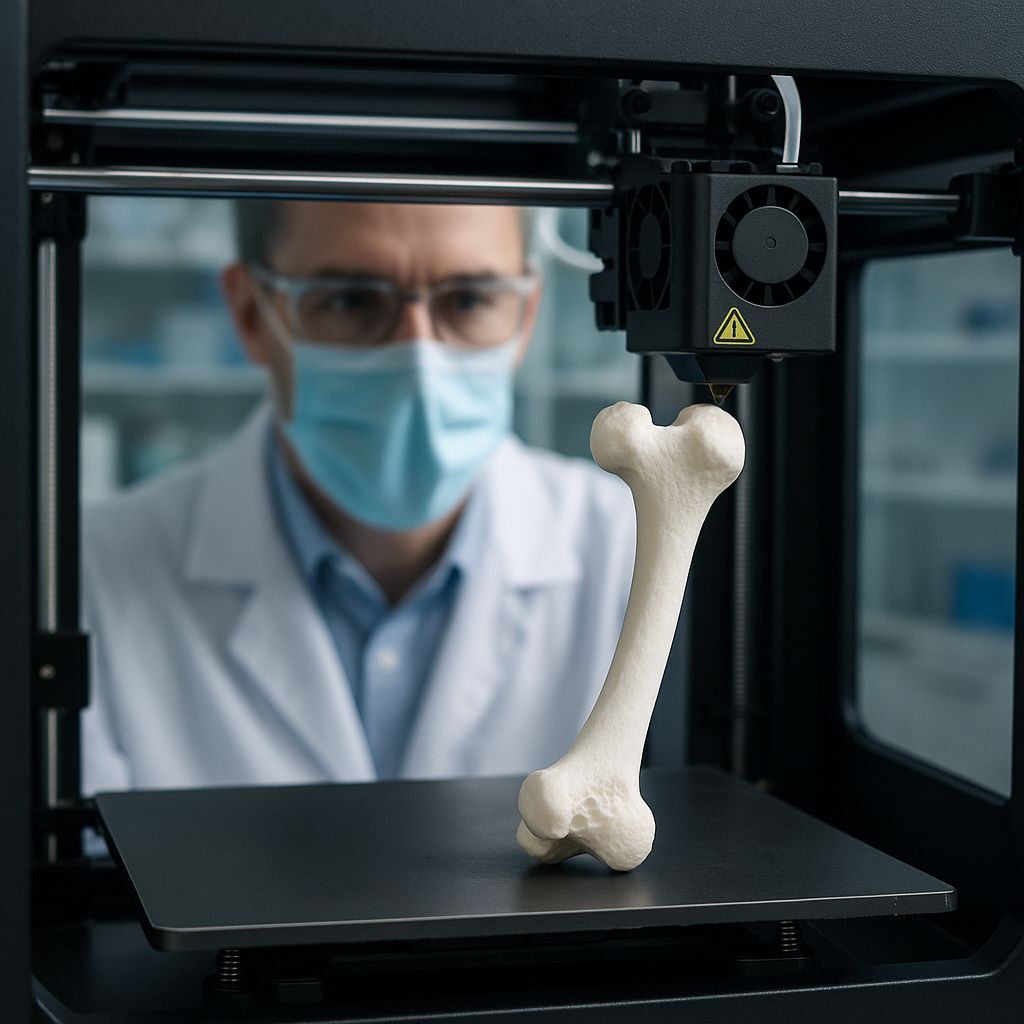

In recent years, 3D printing in healthcare has revolutionised the way devices, implants—and even biological tissues—are designed and made. What once seemed like science fiction is now a practical reality that blends technology, biology and personalised medicine.

In this guide we explore how 3D printing in medicine is changing clinical practice, which materials are used, how bioprinting works, and the most promising innovations for the future.

Medical 3D printing is a branch of additive manufacturing applied to the health sector.

Instead of removing material (as with milling), 3D printing builds an object layer by layer from a digital model.

This technology enables the creation of anatomical models, prosthetics, implants and surgical tools tailored to each patient—with a level of precision unimaginable only a few years ago.

The process typically follows three key stages:

1) 3D Scanning and Modelling

It starts with a CT or MRI scan of the patient, converted into a three-dimensional digital model.

2) Device Design

Clinicians and biomedical engineers use CAD software to design an object perfectly matched to the patient’s anatomy.

3) Printing the Model

The digital file is sent to a 3D printer that deposits biocompatible material (metal, polymer, ceramic or bio-ink) layer by layer to create the physical object.

3D printing in the medical industry is already used successfully across multiple clinical areas. Here are the most relevant:

3D-printed prosthetics are among the most mature and widespread applications.

This technology makes it possible to produce custom, lightweight and cost-effective prostheses precisely adapted to the patient.

Orthopaedic prosthetics: personalised upper and lower limbs, knees, hands and feet.

Cranial or facial prosthetics: widely used in reconstructive surgery, with excellent aesthetic outcomes.

Paediatric prosthetics: light and easy to replace as the child grows.

Personalisation and lower costs have made these prostheses accessible even in developing countries.

Beyond prostheses, medical 3D printing is used to create orthopaedic, dental and maxillofacial implants—as well as 3D printing medical devices for theatre.

Examples include:

Titanium implants for bone reconstruction.

Vertebral cages and biocompatible joint components.

Patient-specific surgical guides, helping surgeons position tools or implants accurately during procedures.

The main advantage is anatomical precision: each device is designed exactly for the patient, reducing operating times and risk.

Bioprinting is one of the most exciting, high-potential innovations within medical 3D printing.

Instead of metals or plastics, this technique uses bio-inks composed of living cells and biomaterials compatible with human tissue.

The goal? To print functional tissues and—one day—organs.

Current uses include:

Skin tissue reconstruction for burns or for pharmacological testing.

Development of artificial cartilage and bone.

Production of mini-organs (organoids) for medical research.

Although printing complex organs (such as hearts or livers) is not yet a clinical reality, progress in recent years fuels optimism for future personalised regenerative medicine.

3D-printed anatomical replicas allow surgeons to study a specific patient’s anatomy before operating. These realistic models are used to:

Simulate complex procedures.

Train medical students and residents.

Communicate with patients, showing concretely what the operation involves.

The result is medicine that is more precise, safer and easier to understand.

Medical 3D printing offers numerous advantages for both clinicians and patients:

Total personalisation — every device can be designed exactly to the patient’s anatomy.

Reduced costs and lead times — prototypes and implants are produced rapidly, without expensive tooling.

Improved comfort and function — especially for prosthetics, fit is optimised.

Continuous innovation — new applications emerge every year, from heart valves to printed bone structures.

More realistic training — clinicians and students can practise on models identical to real organs.

Material choice is crucial for biocompatibility and mechanical performance. The main families include:

| Type | Materials | Applications |

| Biocompatible metals | Titanium, cobalt-chrome, stainless steel | Orthopaedic implants, dental implants |

| Medical polymers and resins | Nylon, PEEK, photopolymer resins | Surgical guides, lightweight prosthetics |

| Ceramics | Zirconia, alumina | Dentistry, orthopaedics |

| Bio-inks | Cells, collagen, gelatin | Bioprinting of tissues and organoids |

Despite rapid progress, medical 3D printing still faces several challenges:

Regulation: medical devices must comply with strict safety standards (e.g., MDR and FDA).

Cost of biomedical printers: advanced technologies—especially in bioprinting—remain expensive.

Material standardisation: uniform protocols are needed to guarantee quality and reliability.

Biological integration: in bioprinting, ensuring cell survival and functional performance remains complex.

The outlook for medical 3D printing is rich with potential. Experts anticipate that in the coming decades we will see:

Custom-printed organs for personalised transplants.

3D-printed medicines, with dosages tailored to the individual patient.

Hospitals with in-house print labs, able to produce implants and anatomical models in real time.

Multidisciplinary collaboration among engineers, biologists and clinicians to develop new therapies.

The medicine of the future will be increasingly digital, personalised and sustainable—and 3D printing in healthcare is one of the key technologies driving this transformation.

3D printing in medicine is no longer experimental; it is already saving lives and improving the quality of care. From 3D-printed prosthetics to bioprinting of living tissues, its applications grow year after year, paving the way for bespoke, more efficient and more human healthcare.

Ultimately, medical 3D printing represents the perfect fusion of technology and biology, and its development will continue to redefine the boundaries of medical science in the 21st century.

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...