3 min read

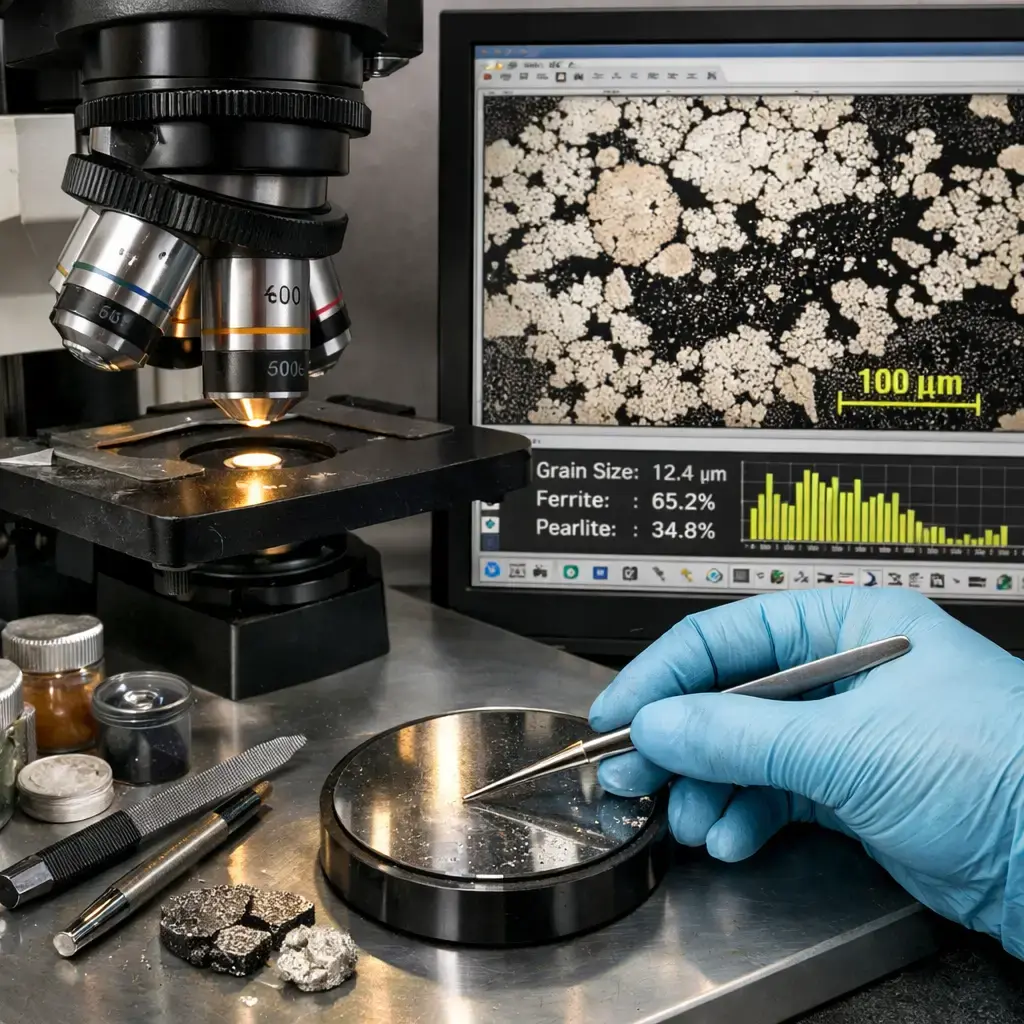

Metallographic Analysis: Microstructure and Quality Control

Metallographic analysis is a fundamental technique used to study the microstructure of metals and alloys. By observing a specially prepared sample...

With global production exceeding 52.2 million tonnes in 2019, stainless steel (inox) remains one of the most widely used materials in the world.

From furniture to mechanical engineering, all the way to high-precision CNC machining, stainless steel has proven to be a reliable, durable and versatile resource ever since its invention by the Englishman Harry Brearley in 1913.

In the following 2026-updated article you will find:

Stainless steel is an alloy composed mainly of:

iron

carbon

chromium (≥10.5%)

nickel, molybdenum and other elements that modify its properties

Its distinctive feature is the spontaneous formation of a passive chromium-oxide layer, invisible and self-renewing, which protects the metal from:

rust

corrosion

oxidation

Tip: If the surface layer is scratched, it automatically regenerates when exposed to oxygen – this is what makes stainless steel truly “stainless”.

CNC machining in progress for a stainless steel part

There are over 100 grades of stainless steel, classified into five major families.

Here are the most important for industrial production, mechanical engineering and CNC machining.

The most common and versatile family.

excellent corrosion resistance

wide thermal range

non-magnetic

highly formable

Used in: furniture, industrial piping, food industry, architecture, CNC machining.

Similar to mild steel but with better corrosion resistance.

magnetic

economical

good ductility

Used in: appliances, interiors, boilers, decorative components.

High hardness and mechanical strength.

magnetic

lower corrosion resistance

Used in: cutlery, turbines, tools, high-stress components.

A mix of austenitic + ferritic structures.

exceptional corrosion resistance

high mechanical strength

good weldability

Used in: marine, chemical, pulp and paper industries.

Also known as semi-austenitic.

extremely high strength and hardness

includes elements such as Al, Nb, Cu

Used in: aerospace, advanced mechanics, high-performance applications.

Parts CNC machined by Weerg with 5-axis Hermle c42u on steel 304

Stainless steel is so widespread thanks to its unique mix of properties:

Fun fact: stainless steel doesn’t heat up easily. Placing a hot object on a stainless-steel handrail hardly increases its temperature.

One of the most common questions concerns the choice between titanium and stainless steel.

metallic alloy

heavier than titanium

more affordable

better weldability

high strength

pure metal

lightweight (40% lower density than stainless steel)

extremely corrosion-resistant

more expensive

more difficult to machine

The choice depends on your project priorities: weight vs durability vs cost.

It depends on:

operating environment

presence of water or salinity

need for formability

budget

mechanical requirements

type of CNC machining

Stainless steel is ubiquitous across many sectors:

Counters, containers, equipment, utensils.

Surgical instruments, prosthetics, sterile devices.

Gears, shafts, brackets, supports, high-strength components.

Bolts, hinges, fittings exposed to saltwater.

Furniture, handles, façades, decorative elements.

Stainless steels in the 300 series, including 304 and 316L, are more difficult to machine than carbon steels but deliver excellent results when handled correctly.

400 series is easier to machine

303 is the easiest stainless steel to mill

304 and 316L require specific tools and optimised parameters

Weerg machines 304 and 316L using Hermle C42U 5-axis milling centres, ideal for difficult materials and for achieving tight tolerances and high-quality finishes.

Learn more about the comparison between stainless steel 304 and 316

Stainless steel is one of the most complete and reliable materials in modern industry.

Its corrosion resistance, durability, hygiene, aesthetic appeal and versatility make it ideal for:

CNC machining

metal 3D printing

mechanical components

structural applications

design products

It is available in hundreds of variants, each designed for specific needs: from aggressive environments to high temperatures, from medical to precision engineering.

Need stainless-steel parts? Upload your file now and get an instant quote

3 min read

Metallographic analysis is a fundamental technique used to study the microstructure of metals and alloys. By observing a specially prepared sample...

2 min read

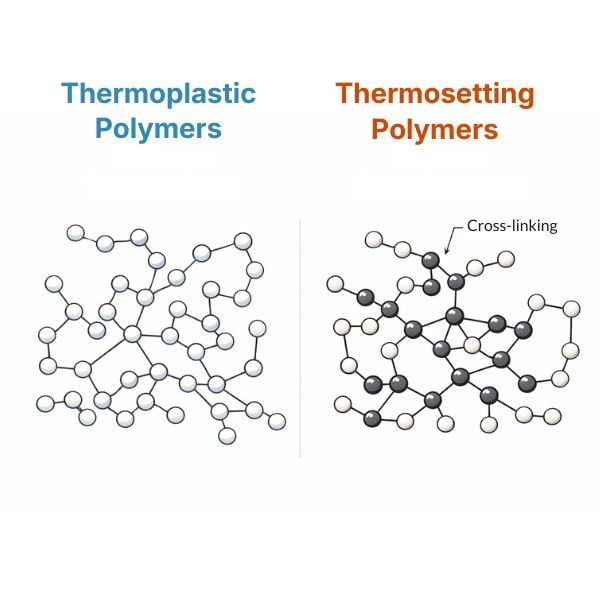

Polymers represent one of the most versatile families of materials in modern industry. Within this category, the fundamental distinction is between ...

3 min read

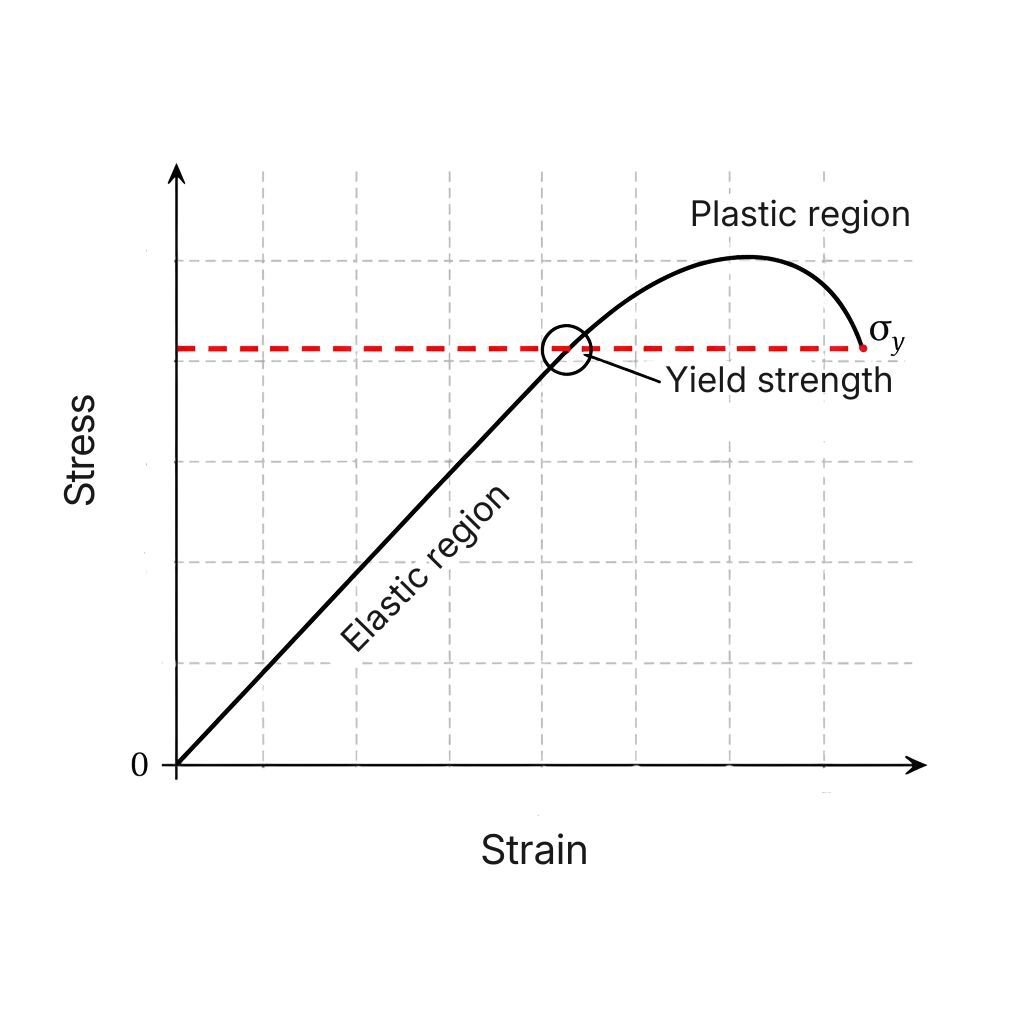

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...