3 min read

Galvanisation: Types of Zinc Coating, Benefits and Differences

Galvanisation is one of the most effective and widely used surface treatments for protecting steel and other metals from corrosion, oxidation and...

HP multi jet fusion 3D printing technology from HP has certainly made impressionable, innovative manufacturing advancements since first launching. Though the entire technology itself is still relatively new, its profound value has generated a rippling effect across diverse industries, quickly becoming a perfect solution for both prototyping and manufacturing. Though this 3D printing service is in high demand, if you are new to the concept, here is an overview of what HP multi jet fusion 3D printing actually is and why it is such a groundbreaking resource. This is why we have a lot of these 3D printers installed in the Weerg factory.

First and foremost, multi jet fusion 3D printing, also referred to as MJF, is a powder-bed, 3D printing resource that was developed by HP. It is used as a manufacturing strategy to create unique parts with exquisite surface finishing in a short amount of time.

The latest MJF 5200 series

In summary, it bonds the agent and powder, similar to the same process as binder jetting. But unlike a point-by-point, laser-based system, MJF was designed to selectively distribute the detailing and fusing agents across the bed of power. Then those layers get fused together using what is called infrared light.

The way this 3D printing service works is quite impressive. For starters, the fusion printhead starts by depositing binding droplets and detailing agents across the polymer powder layers that have been preheated. That said binder works as a heat-absorbing ink, which allows the powder to melt easier to what it binds to.

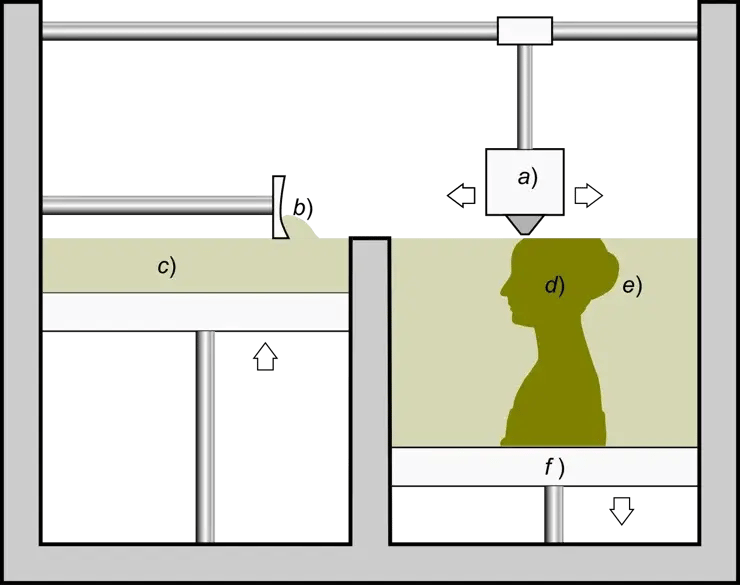

Schematic representation of granular binding fabrication_By Paolo Cignoni

As it works, and as mentioned above, each layer gets fused by the melting features of infrared light, while simultaneously being held by the binding agent. While that is going on, the detailing agent then enables what is known as a “cooling effect.” This cooling provides a crisp edge result around the melted areas, with a primary purpose of preventing a melt-pool from forming into the loose powder.

Next, the power is then distributed on the very top of every solid layer. This is because the power supports the parts as they develop without the need for a support structure in place. This means more creativity, design freedom, and higher quantity capabilities. In the end, this part of the process repeats itself until the part being printed if finalized.

If you are wondering if MJF and selective laser sintering (SLS) are similar, you are not wrong. For example, they both use nylon, and both function by thermally fusing polymer powder layer by layer. So yes, they both are very closely related, but there are some differences between these two technologies that you should know about before making your selection.

One of the key differences between MJF and SLS is the heat sources. MJF uses a particular ink as the fusing agent to promote absorption of the infrared light, whereas SLS uses a laser to scan and then fuse every cross section. This means that the results of the print will be different.

Nylon PA12, due to its versatility and resistance, is one of the most used plastic materials in the world. PA12 3d printed with MJF technology will have a smoother finish and tend to be stronger than those printed with SLS. This is especially true for z-direction printing. This is because MJF’s printing technique has a shorter cooling and post-processing period, which makes it have a competitive advantage over SLS with the same material. In addition, products printed with MJF technology can be recycled up to 80% and reused, compared to up to 50% with SLS technology. In conclusion, not only does MJF technology offer a mechanically and aesthetically better product but also less expensive.

MJF, as noted earlier, was designed to accelerate building speed (up to 10x faster than SLS in our tests) . This means it is a catalyst for producing more products in a shorter time frame, something that SLS is not able to compete with well.

MJF parts feature a finer resolution consisting of 0.020 in., and SLS is 0.030. So, if a smooth finish is a top requirement, then MJF would be the better choice over SLS.

As MJF is a relatively new technology it offers better final parts but a limited choice of materials, at Weerg we currently offer PA12 and PA11 but we plan to include more in the short term.

For functional parts across a variety of industries. Ideal for complex assemblies, housings, enclosures, and watertight applications.

For mechanically loaded functional parts in series with long-term mobile elements such as hinges or parts intended to absorb shocks.

Lightweight material for prototypes, automotive interiors, fluid tubes and tanks, machine parts, medical equipment and cosmetics.

With this overview, you should have a better understanding of what HP multi jet fusion 3D printing is, and more knowledge on what it is truly capable of. From excellent detail accuracy and user-friendly properties, both beginners and experienced professionals can benefit from making high precision, low-cost 3D printed parts. In the end, not only can this streamline processes and produce complex shapes at higher rates, it is fully customizable to fabricate branding within every production.

So, if you are ready to reduce cost, improve performance, and develop quality printed materials, consider to make your parts with a MJF 3D printer...maybe in outsourcing with Weerg.

Sources and further reading

Wikipedia about 3D printing: https://en.wikipedia.org/wiki/3D_printing

HP: https://www8.hp.com/us/en/printers/3d-printers.html

ALL 3D printing, MJF simply explained: https://all3dp.com/2/multi-jet-fusion-mjf-3d-printing-simply-explained/

3 min read

Galvanisation is one of the most effective and widely used surface treatments for protecting steel and other metals from corrosion, oxidation and...

2 min read

VALOI, a brand of the Finnish company Kameratori Oy and specialised in film-digitalisation systems for the home market, has started a collaboration...

2 min read

Stainless steel is one of the most widely used materials in modern industry thanks to its corrosion resistance, durability, and versatility.Among the...