3 min read

CBAM Regulation: What It Is, How It Works and Weerg Compliance

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

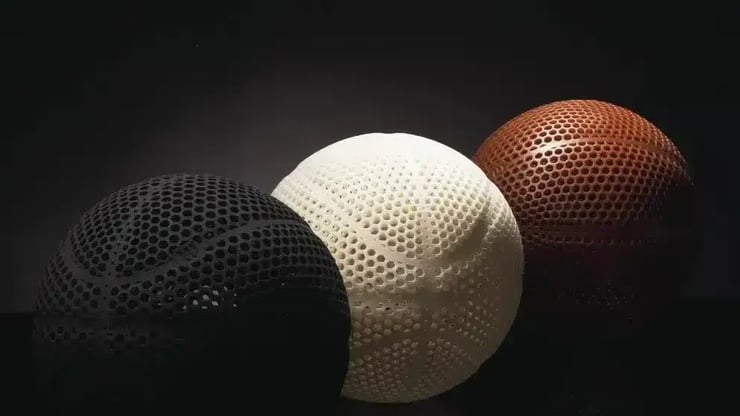

In recent years, 3D printing has made tremendous progress, evolving from an experimental technology into a strategic tool in fields such as medicine, automotive, industrial design and mechanical manufacturing.

One of the most surprising sectors in which it is emerging is sport itself.

Among the most talked-about innovations is the 3D-printed basketball, a revolutionary solution that could forever transform the design, production and use of sports equipment.

What Is a 3D-Printed Basketball?

“Airless” Basketballs: How They Work

How a 3D-Printed Basketball Is Made

The Role of TPU in 3D-Printed Basketballs

Advantages of 3D Printing for Basketballs

The Market for 3D-Printed Basketballs

A 3D-printed basketball is a ball manufactured using additive technologies that deposit or sinter successive layers of plastic or elastomeric material.

The creation process starts from a digital CAD model, allowing millimetric precision and unprecedented customisation.

Each ball can be optimised in terms of:

size

weight

elasticity

internal lattice density

external texture and grip

The result is a unique product, tailor-made to meet the needs of an athlete or team.

These balls are often referred to as 3D-printed airless basketballs, meaning balls that contain no air.

Unlike a traditional basketball, they do not require any internal air chamber.

Their distinctive feature is the internal lattice structure, designed using generative design algorithms, which ensures:

controlled elasticity

consistent bounce

shape stability over time

zero risk of punctures or deflation

The ball therefore does not need to be inflated: its resilience comes directly from the geometry of the lattice and the properties of the material.

This makes it a practical and durable solution, particularly useful in outdoor environments where traditional balls often suffer damage and lose pressure.

Image by Wired

The production of a 3D-printed basketball follows a highly technological process:

It begins with CAD modelling. Engineers define:

the internal lattice structure

variable geometries to adjust hardness and bounce

the surface texture for grip

Not all materials are suitable. They must offer:

elasticity

strength

shape memory

durability

For this reason, the best choice is almost always an elastomeric polymer such as TPU.

The ball is produced with technologies such as:

SLS (Selective Laser Sintering)

MJF (Multi Jet Fusion)

elastomeric SLA

The process may take from a few hours to several days depending on complexity.

The ball is tested to verify:

bounce

flexibility

strength

uniformity of shape

Only after passing all standards is it considered complete.

TPU (thermoplastic polyurethane) is the key material that has enabled these solutions to evolve from conceptual prototypes into fully functional products.

Why is TPU ideal?

High elasticity

Shock absorption

Abrasion resistance

Long-term stability

Excellent grip

Adjustable hardness depending on use

TPU remains stable even after hundreds of deformations—an essential characteristic for a ball that must be repeatedly compressed and released.

Companies such as Weerg use high-quality TPU through MJF to create elastic, robust and reliable parts—perfect even for sports items such as airless basketballs.

For now, these balls remain a niche product, used mainly for:

technology demonstrations

prototypes

performance testing

limited editions

But the market is growing rapidly.

With advances in additive technologies and falling production costs, airless basketballs are likely to become mainstream—especially in outdoor and semi-professional settings.

Global sports brands are investing in research and development to bring these solutions to players worldwide.

Conclusions

3D-printed basketballs represent just the beginning of a broader shift: the entry of additive manufacturing into the world of sport.

They eliminate the air chamber, improve grip, ensure consistent performance and open the door to a level of customisation never seen before.

Leading this change is Weerg, which—thanks to advanced technologies and elastomeric materials such as TPU—can produce innovative, durable and fully customisable sports components.

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

3 min read

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

3 min read

How Environmental Management System certification strengthens the quality of our production processes and the value we deliver to our partners