3 min read

Yield Strength: Elastic Limit of Materials

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D printing.

It defines the limit beyond which a material begins to deform permanently. Knowing it is essential for designing safe, reliable and durable components.

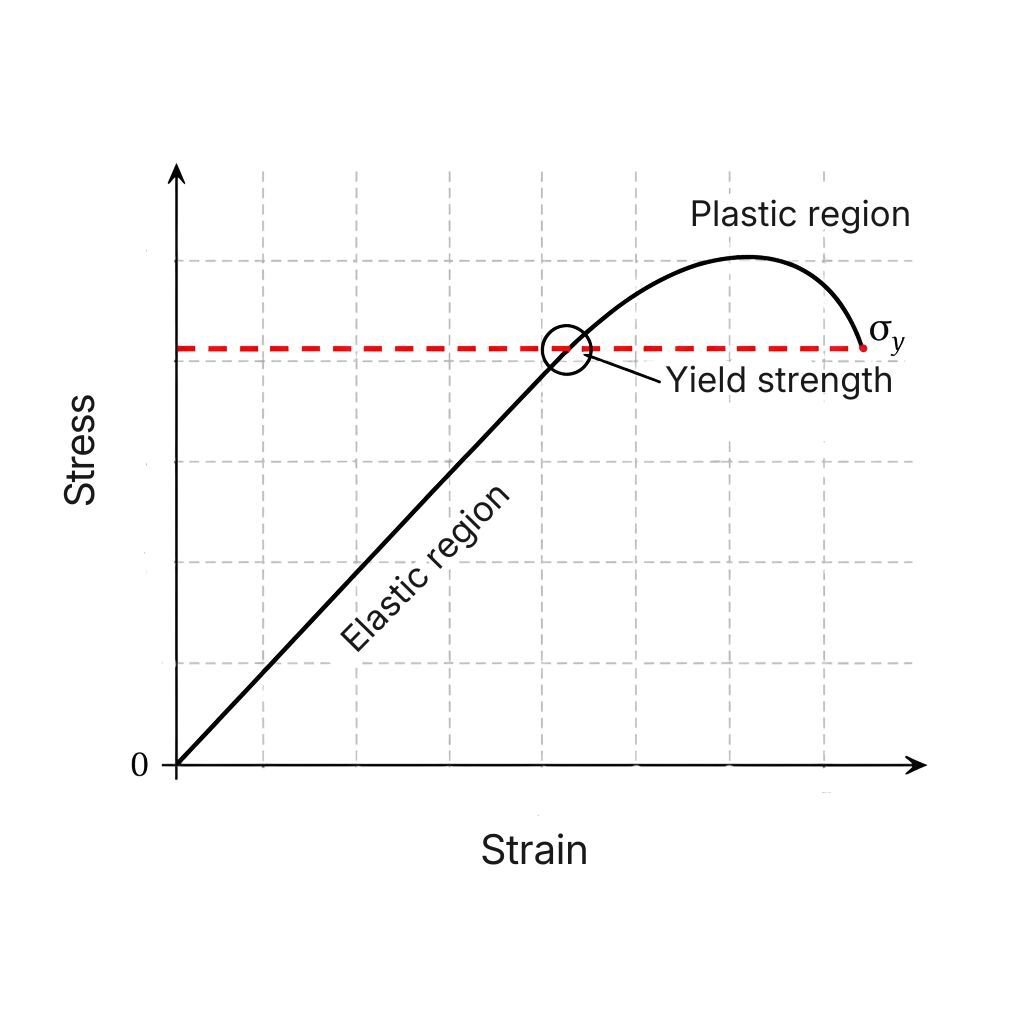

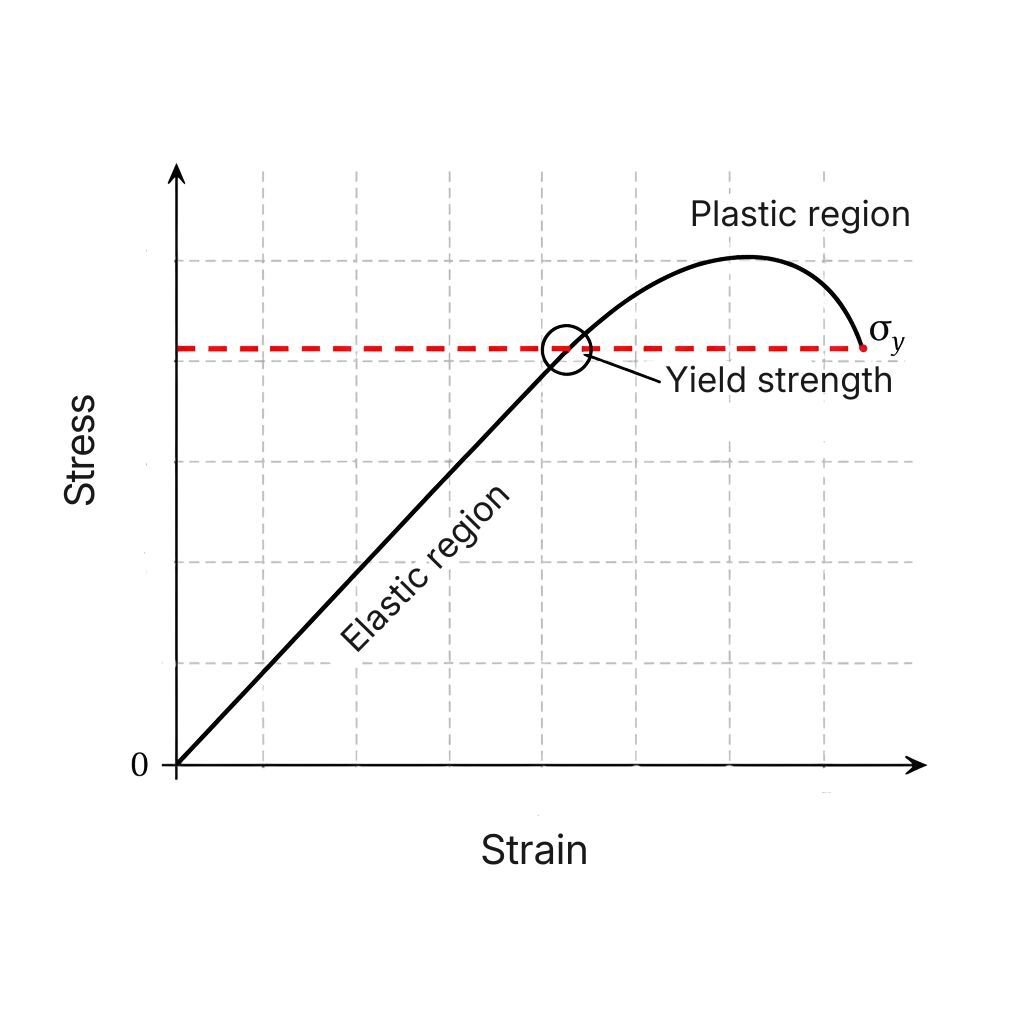

Yield strength (σᵧ) is the stress value at which a material transitions from elastic (reversible) deformation to plastic (irreversible) deformation.

Below σᵧ → the material returns to its original shape once the load is removed.

Above σᵧ → the deformation remains even after the load is removed.

In practice, it represents the safe operating limit for most structural components.

Yield strength is calculated as:

σᵧ = Fᵧ / A

Where:

In practice, yield strength is measured through a tensile test:

For materials that do not show a clear yield point (such as many aluminium alloys), the 0.2% offset method is used. It identifies the stress corresponding to a permanent plastic strain of 0.2%.

This is the most widely used method in industry.

UPLOAD YOUR FILE AND SPEAK WITH AN EXPERT

Yield strength is expressed in:

Yield strength is a key parameter because it:

In most designs, engineers work well below the ultimate strength, using yield strength as the main reference.

It is important not to confuse these two values:

A material can:

| Material | Yield stress (≈) |

| Aluminum 6061-T6 | ~240 MPa |

| Structural steel S235JR | ~235 MPa |

| Steel S355J2 | ~355 MPa |

| Stainless steel 304 | ~215 MPa |

| Titanium Ti-6Al-4V | ~880 MPa |

| Nylon PA12 | ~45-50 MPa |

| PLA (3D printing) | ~50-60 MPa |

Values depend on heat treatment, manufacturing process and material orientation.

In 3D printing, yield strength also depends on:

Examples:

It is essential to consider both the material and the manufacturing process, not just theoretical data.

In design, the following is often used:

σₐₘₘ = σᵧ / FS

Where:

This ensures the component always operates within the elastic range.

Yield strength is the key parameter for understanding when a material stops behaving elastically and begins to deform permanently.

It is essential for:

Designing below the yield strength means designing safely.

UPLOAD YOUR FILE AND CHOOSE THE MOST SUITABLE MATERIAL FOR YOUR PROJECT

The yield strength of steel varies depending on the type and heat treatment. In general:

This value indicates the maximum load steel can withstand without permanent deformation and is the primary reference for structural design.

No. Some materials, such as many aluminium alloys, do not exhibit a distinct yield point. In these cases, the 0.2% offset method is used to define yield strength conventionally.

Yield strength is the stress value beyond which a material begins to deform permanently. Below this limit, deformation is elastic and reversible.

The former is the safe operating limit; the latter indicates when the material fails.

3 min read

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...