3 min read

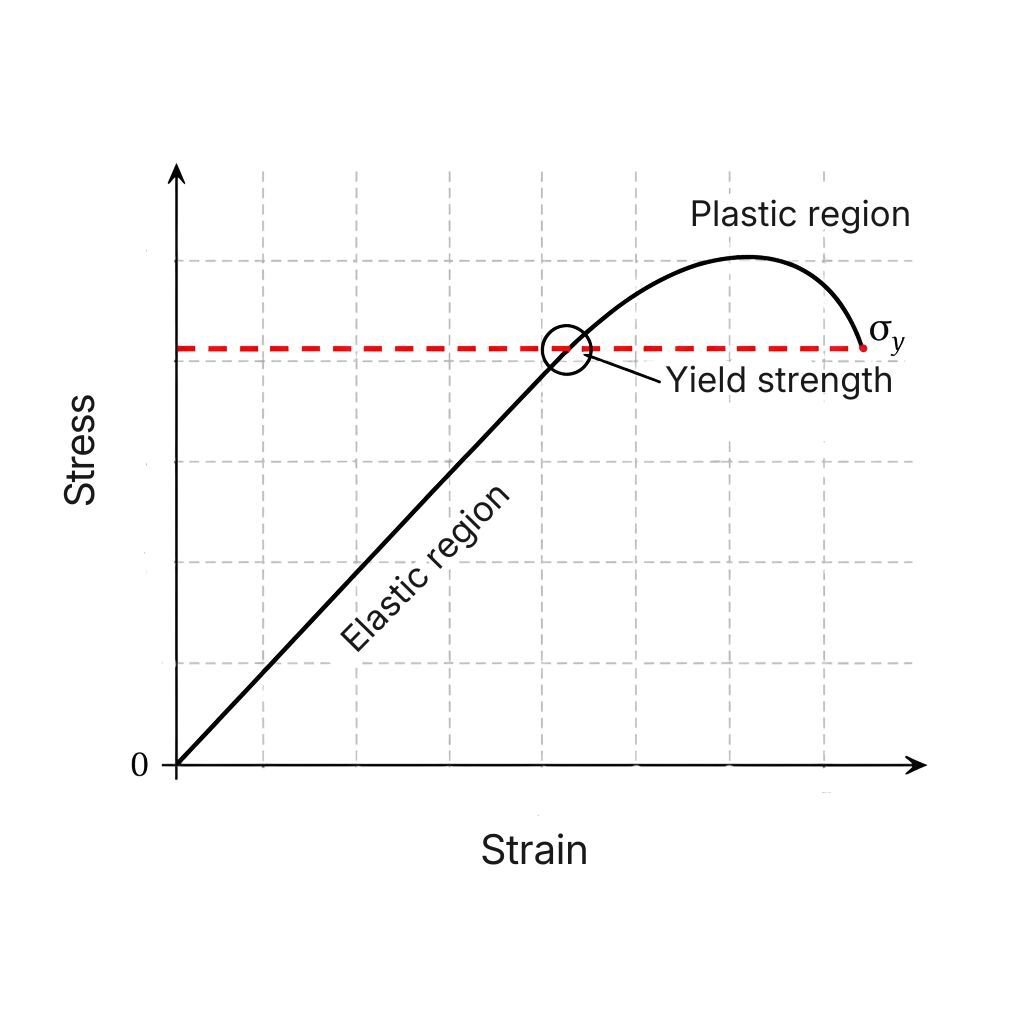

Yield Strength: Elastic Limit of Materials

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...

3 min read

![]() Weerg staff

:

Jan 14, 2026

Weerg staff

:

Jan 14, 2026

The Brinell test is one of the oldest and most reliable methods for measuring the hardness of materials, particularly metals.

Even today it is widely used in metallurgy, quality control, industrial production and research, especially when analysing heterogeneous or coarse-grained materials.

In this guide you will learn:

The Brinell hardness test is a mechanical test that measures a material’s resistance to penetration by a hard indenter under load.

The method is named after the Swedish engineer Johan August Brinell, who developed it in 1900 to analyse metallic materials used in industry.

In practice, the test evaluates how much a material deforms when it is pressed with force by a hard ball.

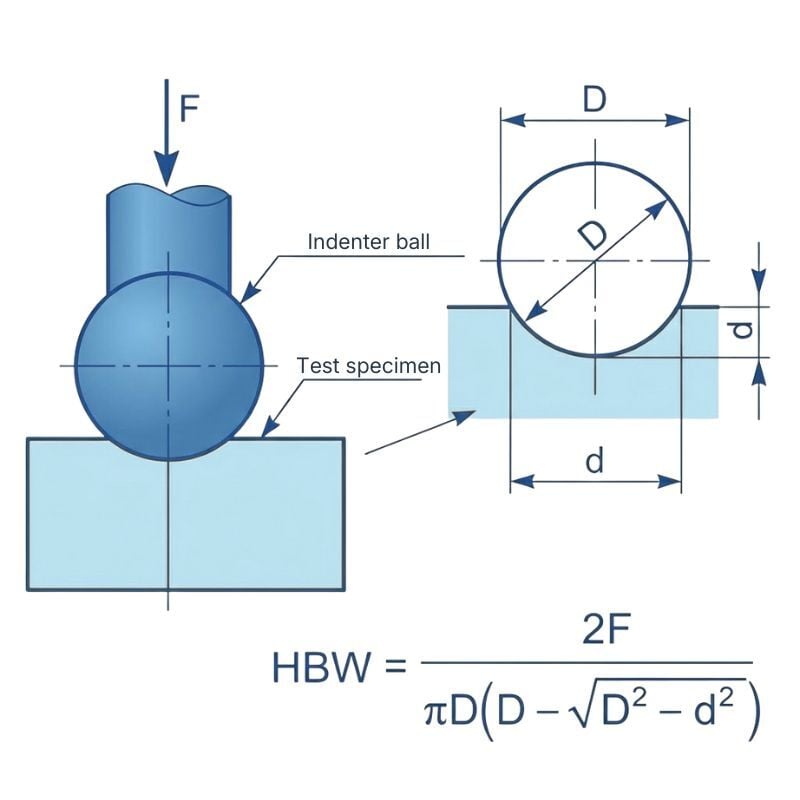

Brinell hardness is expressed as HB or HBW (when using tungsten carbide) and is calculated using the formula:

Where:

F = applied load (kgf or N)

D = ball diameter (mm)

d = average diameter of the indentation (mm)

In industrial practice, the value is often read directly from tables or from the testing machine’s software.

Brinell hardness measures the surface plastic resistance of a material, i.e. its ability to resist:

permanent deformation

indentation

mechanical wear

It does not measure:

tensile strength

toughness

impact resistance

However, it provides very useful information about machinability, wear resistance and the overall mechanical behaviour of the material.

The test follows a standardised procedure:

A hardened steel or tungsten carbide ball is pressed against the surface of the material.

A constant load is applied for a defined time (typically 10–15 seconds).

After removing the load, the diameter of the indentation left on the surface is measured.

From the indentation size, the Brinell hardness number (HB or HBW) is calculated.

Larger indentation → softer material

Smaller indentation → harder material

Ball diameter: 1, 2.5, 5 or 10 mm

Applied load: from 500 to 3000 kgf

Dwell time: 10–15 seconds

Reference standards:

ISO 6506

ASTM E10

The choice of parameters depends on:

material type

expected hardness

specimen thickness

The Brinell test is particularly suitable for:

Not ideal for:

Brinell is less precise than Vickers, but more reliable on heterogeneous materials.

|

Feature |

Brinell (HB/HBW) |

Rockwell (HR) |

Vickers (HV) |

|

Indenter type |

Ball (steel or carbide) |

Diamond cone or ball |

Diamond pyramid |

|

Indentation size |

Large |

Small |

Very small |

|

Reading method |

Optical (indent diameter) |

Direct (automatic scale) |

Optical (diagonal measurement) |

|

Accuracy |

Medium |

Medium |

High |

|

Test speed |

Medium |

High |

Medium |

|

Invasiveness |

High |

Low |

Very Low |

|

Ideal materials |

Cast irons, castings, structural steels |

Heat-treated steels, finished parts |

Any material |

|

Heterogeneous materials |

Excellent |

Limited |

Limited |

|

Thin layers/coatings |

No |

No |

Yes |

|

In-line quality control |

Poorly suitable |

Ideal |

Poorly suitable |

|

Main standards |

ISO 6506 / ASTM E10 |

ISO 6508 / ASTM E18 |

ISO 6507 / ASTM E384 |

the material has a heterogeneous structure

a reliable average hardness value is required

the component is large

micrometric precision is not a priority

results must be compared with historical data

The Brinell test remains a fundamental tool for measuring metal hardness, especially when analyzing massive, heterogeneous or structural materials.

While not the most accurate method by any means, it offers a reliable and representative view of the mechanical behavior of the material, making it still an industry standard today.

The Brinell test remains a fundamental tool for measuring the hardness of metals, especially when analysing massive, heterogeneous or structural materials.

Although it is not the most precise method available, it provides a reliable and representative view of a material’s mechanical behaviour, making it an industrial standard even today.

Are you choosing a material for a structural component?

Upload your file and get technical support for the production of your component

The three main hardness tests used in industry are:

Brinell (HB/HBW): suitable for large, non-homogeneous materials

Rockwell (HR): fast and ideal for production quality control

Vickers (HV): very precise, usable on any material and thickness

Brinell hardness is calculated by measuring the diameter of the indentation left by a ball pressed into the material under a known load.

The formula is:

Where:

F is the applied force

D is the ball diameter

d is the average diameter of the indentation

In practice, the value is often obtained using standard tables or automatic machine readings.

HBN is not a hardness value, but a material: hexagonal boron nitride (h-BN).

This material is not normally measured using the Brinell test because it is a solid lubricating ceramic.

For comparison:

h-BN → soft material, similar to graphite

c-BN (cubic boron nitride) → very high hardness of ≈ 4500–5000 HV, second only to diamond

The Brinell test uses a large-diameter indenter, producing a wide indentation.

This allows averaging of microstructural differences within the material (coarse grains, inclusions, different phases), making the result more representative than tests with smaller indentations such as Rockwell or Vickers.

For this reason, Brinell is ideal for:

cast irons

castings

structural steels

non-uniform materials

3 min read

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...