4 min read

Uses of Metals: Types, Classifications and Applications

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

Since the birth of 3D printing in the 1980s and through to today’s modern industrial processes, additive manufacturing has made enormous progress.

Among the most widespread and representative technologies today are:

In this guide, we examine the differences, advantages, materials, applications and limitations of the two technologies, to help you choose the ideal one for your project.

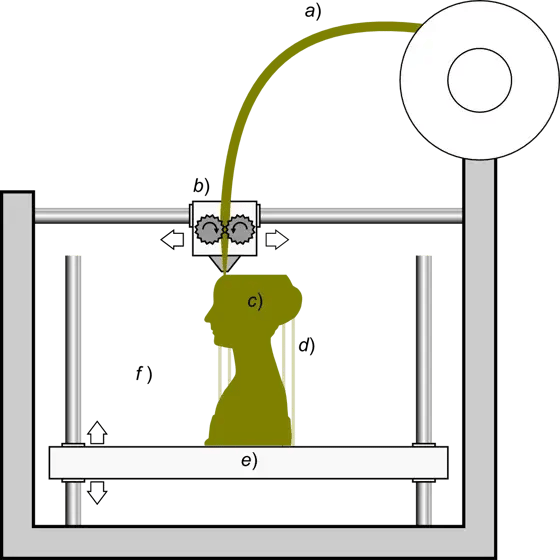

This is the most widespread 3D printing technology among hobbyists, designers and small workshops.

It uses a thermoplastic filament that is melted and extruded through a nozzle, building the part layer by layer.

It is easy to use, inexpensive (consumer printers from €100–200) and ideal for quick prototypes and concept testing.

In FDM technology, a filament a) of plastic material is fed through a heated moving head b) which melts and extrudes it, depositing it, layer by layer, in the desired shape c). A mobile platform e) lowers after each layer has been deposited. For this type of 3D printing technology additional vertical support structures are required d) to support the protruding parts. Source: Wikipedia by Paolo Cignoni

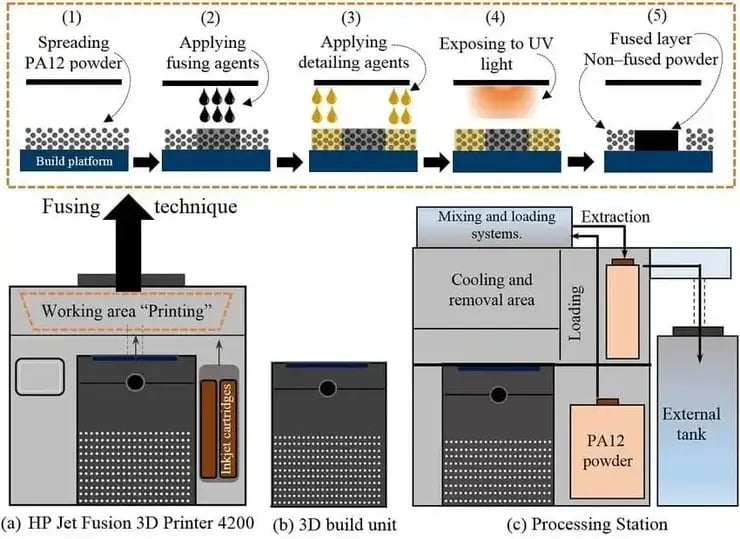

This is a professional technology developed by HP and introduced in 2016.

It uses a nylon powder bed and an inkjet array that selectively deposits fusing and detailing agents, which are then melted by IR lamps.

The result?

Isotropic, strong parts, support-free, with quality comparable to injection moulding.

One of 12 HP Multi Jet Fusion printers installed by Weerg. Get an instant quote.

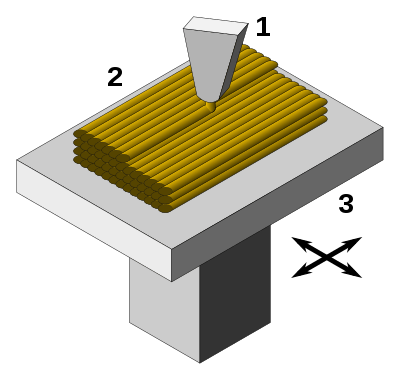

The 3D model is “sliced” using software (Cura, PrusaSlicer).

The printer melts the filament and deposits it through a nozzle.

Each layer solidifies before the next one is added.

Supports are required for overhangs.

Typical layer height: 0.1–0.5 mm.

Printing process: 1 - Print extruder, 2 - Deposited material, 3 - Construction plan.

Source: Wikipedia by Paolo Cignoni

A roller spreads a thin layer of powder.

Inkjet heads deposit fusing and detailing agents.

An IR lamp selectively melts the powder.

The surrounding powder supports the part → no supports required.

At the end of the print, the build box is removed and the parts are cleaned.

MJF productivity is approx. 300 cm³/h, compared with approx. 10 cm³/h for FDM.

Multi Jet Fusion (MJF) process scheme: (a) stages 1-5 of the fusion process); (b) 3D construction unit; (c) processing station. Source: research gate

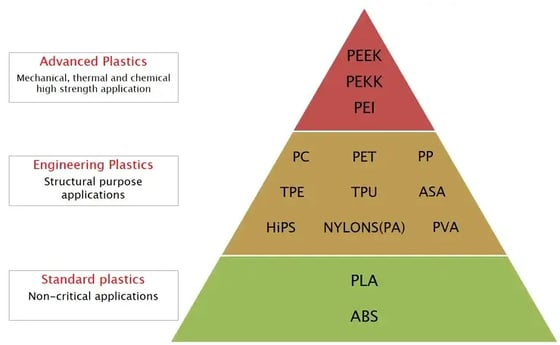

Most commonly used:

PLA → easy, good aesthetics, biodegradable

ABS → strong but prone to warping

PETG → balance between strength and ease of printing

TPU → flexible

Nylon → strong but difficult to print

Professional FDM printers (from €25,000) can print high-performance materials:

PEEK, Carbon PEEK, Ultem, advanced composites

FDM printing offers a good range of materials. Source filament to print

MJF processes high-performance industrial materials, including:

PA12

PA11

PA12 GF (glass-filled)

TPU

PP (Polypropylene)

These materials offer mechanical properties very close to injection moulding.

FDM: visible layers, rough surface

MJF: uniform, “velvety”, professional finish

FDM: variable, depends on the printer

MJF: very high and repeatable

FDM: anisotropic → weakness along the Z-axis

MJF: isotropic → consistent strength in all directions

FDM: limited in fine details; requires supports

MJF: excellent detail, no supports, ideal for complex geometries

FDM printing farm: the Prusa printing farm has over 300 FDM printers in a single room

rapid prototyping

concept models

low-cost, non-functional parts

experimentation with special materials

Perfect for: makers, students, designers in the early stages of development.

strong, functional prototypes

small and medium-batch production

technical components

mechanical parts, snap-fits, housings

complex geometries without supports

Perfect for: engineering, automotive, medical, robotics, advanced manufacturing.

Advantages

inexpensive

easy to use

wide material variety

excellent for early prototypes

Disadvantages

low precision

poor surface aesthetics

limited repeatability

common issues: warping, clogging, delamination

supports always required

Advantages

industrial-grade quality

isotropic, strong parts

no supports

high productivity

uniform finish

ideal for end-use production

Disadvantages

higher cost compared with FDM

fewer materials

requires industrial equipment (≈€500,000)

| Characteristic | FDM | MJF |

|---|---|---|

| Surface quality | ★★☆☆☆ (visible layers) | ★★★★☆ (uniform, fine) |

| Accuracy | ★★☆☆☆ | ★★★★★ |

| Mechanical strength | ★★★☆☆ | ★★★★★ (isotropic) |

| Materials | Very varied | Industrial, high-performance |

| Supports | Required | None |

| Production speed | Slow (10 cm³/h) | Very fast (300 cm³/h) |

| Repeatability | Medium | High |

| Printer cost | €100–25,000 | ~€500,000 |

| Applications | Prototypes, hobby | Functional prototypes, production |

The real question is not “which technology is better?” but rather:

Which technology is better for your purpose?

Choose FDM if:

you have a limited budget

you need fast, low-cost prototyping

material variety is important to you

Choose MJF if:

you need strong, functional parts

you require industrial-grade quality

you need small/medium-batch production

you want complex geometries without supports

MJF is currently one of the most significant advances in industrial 3D printing, capable of competing with injection moulding in cost, speed and performance.

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...