3 min read

Nylon: Uses, Industrial Applications and Advantages

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

One of the most common challenges in 3D printing is achieving a smooth surface finish.

Visible layer lines, rough textures, and small imperfections are especially common in FDM prints, but even resin and powder-based prints may require post-processing to look truly professional.

In this guide, you’ll learn how to make 3D prints smooth, covering the most effective techniques for different printing technologies, materials, and use cases.

3D prints are built layer by layer, and those layers are often visible on the final object. Surface roughness depends on several factors:

Understanding the cause helps you choose the right smoothing method.

FDM prints usually need the most finishing work due to visible layer lines.

Best for: PLA, ABS, PETG, Nylon

Steps:

Pros: inexpensive, precise

Cons: time-consuming, manual effort

Best for: parts that will be painted

How it works:

Result: very smooth, paint-ready surface

Acetone slightly melts the surface of ABS, creating a glossy finish.

How it works:

Pros: excellent finish

Cons: works only on ABS, affects tolerances, requires safety precautions

A heat gun can soften surface layers.

Tip: keep the gun moving to avoid warping.

Risk: deformation and loss of detail if overheated.

Products like epoxy resin fill layer lines.

Pros: strong, smooth, glossy

Cons: adds thickness and weight

Resin prints (SLA, MSLA, DLP) already have a high-quality surface, but they still benefit from post-processing.

Incomplete curing causes sticky or uneven surfaces.

Use very fine grit (600–1000+) to remove support marks.

Enhances smoothness and prepares the part for painting.

Powder-based prints have a slightly grainy texture.

Creates a uniform, matte surface.

Used mainly for PA12 and PA11.

Benefits:

This is an industrial-grade solution, often offered by professional services.

Ideal for batches of parts with simple geometry.

Prevention is better than post-processing.

Lower layers = smoother surfaces.

Avoid steep vertical surfaces where layer lines are most visible.

Slower printing improves layer bonding and appearance.

0.2 mm nozzles produce finer details than 0.4 mm.

|

Technology |

Best Smoothing Methods |

|

FDM |

Sanding, filler primer, acetone (ABS), epoxy |

|

SLA / MSLA |

IPA wash, UV curing, light sanding |

|

MJF / SLS |

Bead blasting, vapor smoothing |

|

Metal 3D Printing |

Shot peening, machining, polishing |

Consider professional finishing if:

Industrial processes like vapor smoothing offer results that are difficult to achieve at home.

Making 3D prints smooth is a combination of:

From simple sanding to advanced vapor smoothing, there’s a solution for every project and budget.

Want perfectly smooth 3D-printed parts?

Upload your file and choose professional post-processing for a flawless finish

3 min read

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

3 min read

How Environmental Management System certification strengthens the quality of our production processes and the value we deliver to our partners

3 min read

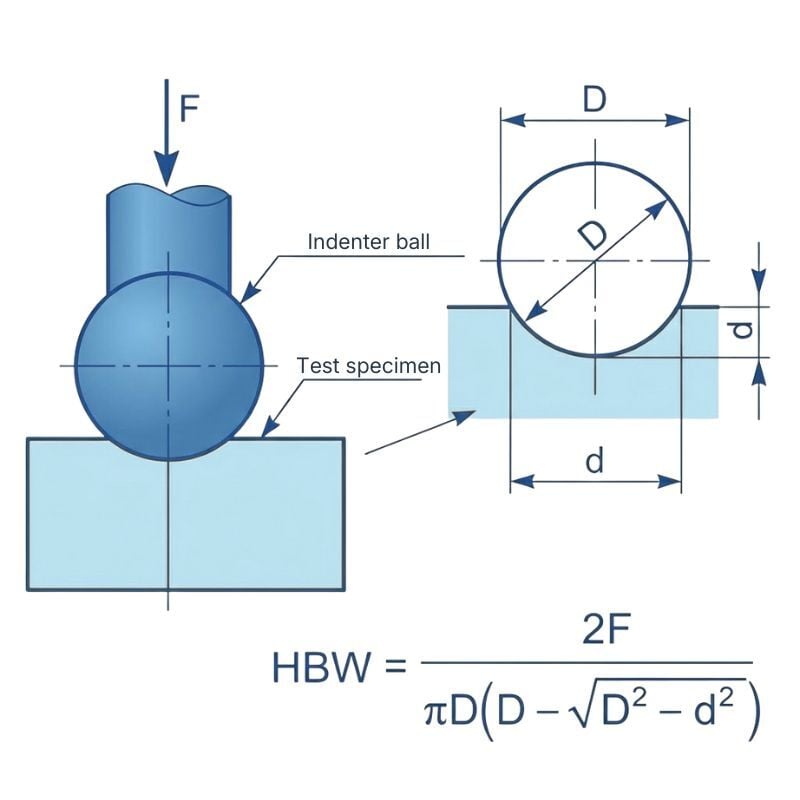

The Brinell test is one of the oldest and most reliable methods for measuring the hardness of materials, particularly metals.Even today it is widely...