3 min read

CBAM Regulation: What It Is, How It Works and Weerg Compliance

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

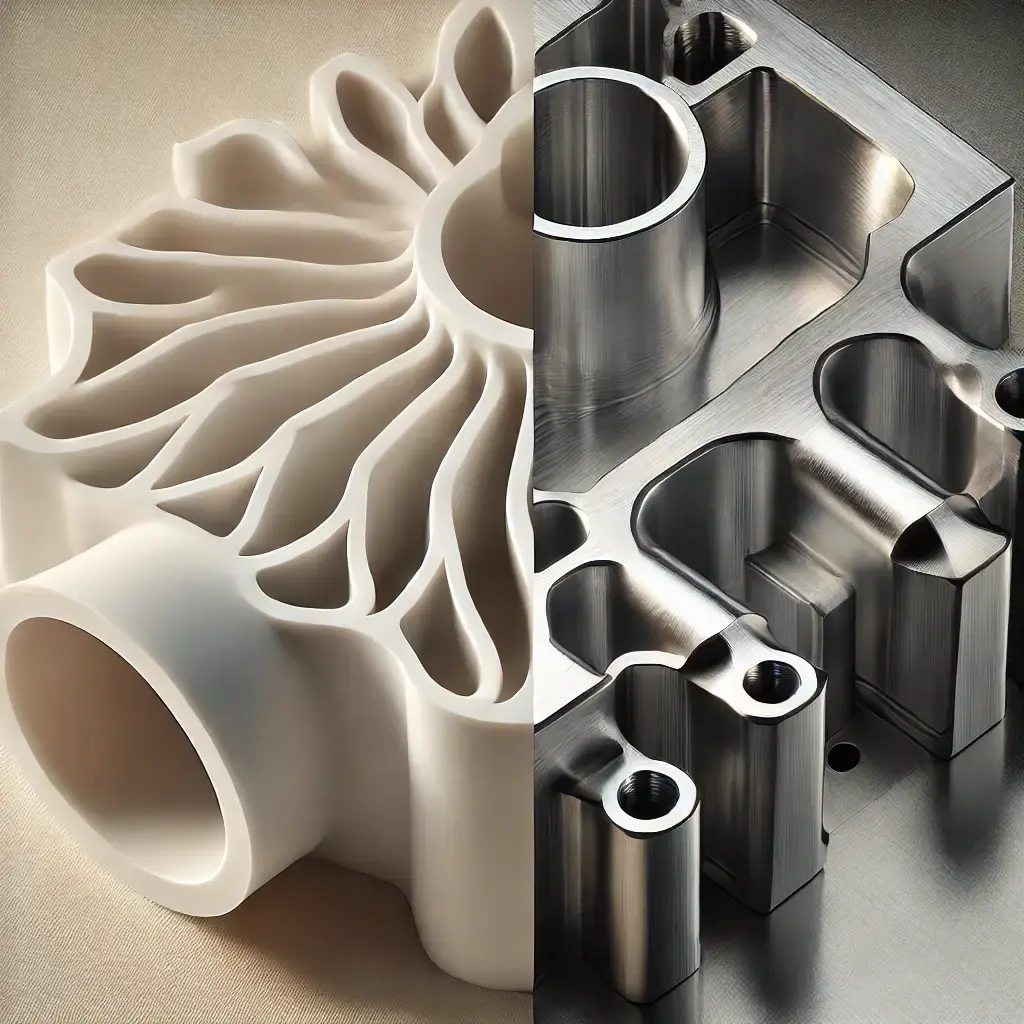

In the world of industrial production and CNC machining, choosing the right material is a crucial step in achieving quality, precision and long-lasting performance.

Among the most in-demand materials are PVC and aluminium, both versatile and widely used, but fundamentally different in terms of properties, strength and field of application.

In this 2025 Guide, we clearly and technically analyse the differences between PVC and aluminium in CNC machining, helping you identify the best material for your project.

What you’ll find in this guide:

PVC (Polyvinyl Chloride) is a rigid, cost-effective plastic that is easy to machine.

In CNC applications it is valued for its dimensional stability, its chemical resistance and its excellent electrical insulation.

Very lightweight

Self-extinguishing

Excellent chemical resistance

Electrical and thermal insulator

Low moisture absorption

Good dimensional stability

Easy to mill, turn and drill, even with standard tools.

Low tool wear → shorter cycle times and reduced costs.

Accurate, clean surfaces and tight tolerances.

Ideal for prototypes and small batches.

Lower mechanical strength compared with metals.

Sensitive to high temperatures (softening above 60–70°C).

Sensitive to UV radiation if not stabilised.

Electronic components

Non-structural mechanical parts

Spacers, guards, panels

Chemical and plant engineering sectors.

Aluminium is a lightweight yet strong metal, ideal for structural applications and high-performance technical components.

Lightweight yet very strong

Excellent rigidity

Good corrosion resistance

High thermal conductivity

100% recyclable

Very tight tolerances (ISO fine or medium class)

Excellent surface finish

Excellent geometrical accuracy

Suitable for high loads and structural parts

Can be milled, turned and drilled at high speed

Higher cost compared with PVC

Poor thermal and electrical insulation

Hard alloys (e.g. 7075) are more difficult to weld

Structural frames

Supports, brackets and housings

Aerospace and automotive components

Heat sinks

Precision aesthetic parts

| Characteristic | PVC | Aluminium |

|---|---|---|

| Weight | Very lightweight | Lightweight but heavier than PVC |

| Mechanical strength |

Low | High |

| Thermal resistance | Low | Very good |

| Electrical insulation | Excellent | Poor |

| Chemical resistance | Excellent | Good |

| Material cost | Low | Medium |

| CNC machinability | Very easy | Precise and professional |

| Rigidity | Medium | High |

| Outdoor durability | Medium (UV) | High |

| Sustainability | Low energy impact | Highly recyclable |

you want a cost-effective material that is easy to machine;

the part is not subject to high loads;

you need electrical or thermal insulation;

the environment is chemically aggressive;

it is important to reduce weight.

you require mechanical strength and durability;

the part is structural or high performance;

you are looking for CNC precision and high-quality surfaces;

the part will be used outdoors;

the project requires sustainability and recyclability.

The choice between PVC or aluminium depends on the requirements of your project:

PVC guarantees cost-effectiveness, insulation and ease of machining,

while aluminium offers strength, precision and long-term resistance.

Both materials perform excellently in CNC machining, but with very different performance profiles and fields of use.

At Weerg, we manufacture CNC components in PVC and aluminium using state-of-the-art machinery, guaranteeing tight tolerances, quick turnaround times and industrial-grade quality.

Upload your file now and get an instant quote for your PVC or aluminium parts

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

3 min read

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

3 min read

How Environmental Management System certification strengthens the quality of our production processes and the value we deliver to our partners