4 min read

Uses of Metals: Types, Classifications and Applications

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

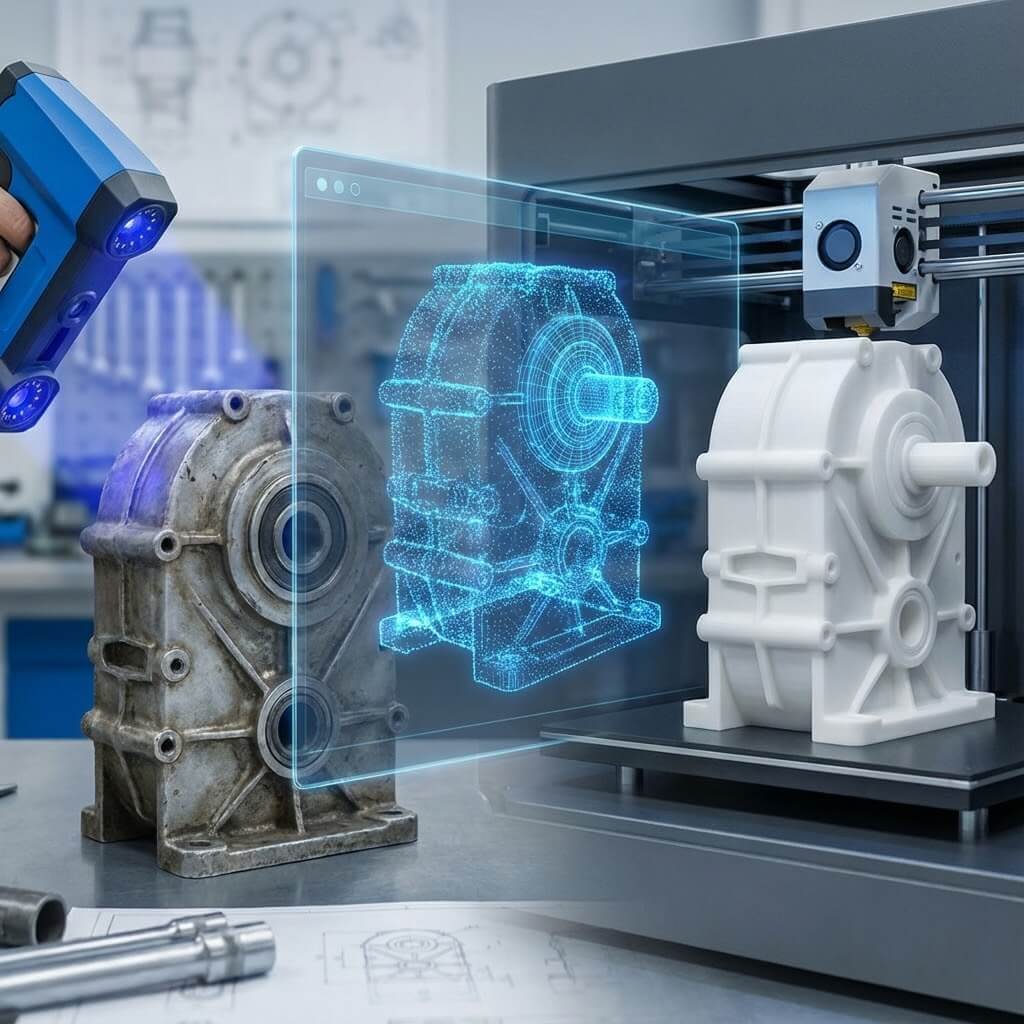

Reverse engineering is an increasingly widespread practice in modern industry, mechanical design and digital manufacturing.

It allows the digital model of a physical object to be reconstructed, even when drawings, CAD files or technical documentation no longer exist.

Thanks to the evolution of 3D scanners, CAD software and manufacturing technologies such as CNC machining and 3D printing, reverse engineering is now a strategic tool for repairing, improving, reproducing or optimising existing components.

Reverse engineering is the process of starting from a real object to trace back its digital model, geometry, materials and functional characteristics.

In practice, it is the opposite of traditional design:

The end result is an editable 3D file, ready for:

Reverse engineering is used in many practical contexts:

reconstructing out-of-production parts

repairing damaged components

replicating parts without original drawings

improving or lightweighting an existing component

adapting a part to new requirements

checking tolerances and deformations

analysing competitors’ products

It is very common in sectors where machine downtime is costly or where spare parts are no longer available.

The process generally follows a number of standard steps.

The object is digitised using:

3D scanners (laser or structured light)

tomography (CT scan) for internal features

manual measurements (callipers, CMM) for simple geometries

The scan produces a mesh (point cloud or triangulated surface).

The mesh is:

The model is converted into parametric CAD (solids and surfaces), editable and ready for production.

The final CAD file can be:

3D printed

CNC machined

structurally optimised

adapted to new materials

3D printing is one of the main allies of reverse engineering.

rapid production of the reconstructed part

no need for moulds

ability to use materials different from the original

easy iteration and correction

It is ideal for:

custom spare parts

functional prototypes

obsolete components

bespoke adapters and supports

When the following are required:

tight tolerances

metallic materials

high mechanical strength

reverse engineering is often combined with CNC milling or turning.

The reconstructed model is adapted to:

machining strategies

required tolerances

final material

Reverse engineering is used across many industries.

spare parts no longer available

components of legacy machinery

custom components

vehicle restoration

performance improvement

reduces time and costs

avoids complete redesign

enables targeted improvements

allows digitisation of physical objects

increases manufacturing flexibility

enables on-demand production

Reverse engineering is not always straightforward:

highly complex geometries require time

deformed parts can distort measurements

advanced CAD skills are required

final quality depends on the initial scan

In addition, legal and patent aspects must always be considered when replicating an existing product.

Reverse engineering is now a fundamental tool for modern manufacturing, especially when integrated with 3D printing and CNC machining.

It allows a physical object to be transformed into a digital asset that can be improved and reproduced, reducing costs, lead times and dependence on original suppliers.

Whether it is an industrial spare part, a custom component or a restoration project, reverse engineering paves the way for more flexible, sustainable and intelligent production.

Do you have a component to reconstruct or improve?

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...