3 min read

CBAM Regulation: What It Is, How It Works and Weerg Compliance

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

2 min read

![]() Weerg staff

:

Oct 30, 2025

Weerg staff

:

Oct 30, 2025

In the field of advanced robotics, Italy stands out for its ability to combine research, innovation and manufacturing expertise.

Among these leading companies, Oversonic Robotics is one of the most visionary, specialising in the design and development of intelligent humanoid robots for industrial, assistive and human-support applications.

To bring these complex systems to life, Oversonic Robotics chose Weerg as its partner for the production of CNC-machined aluminium 6082 components — materials requiring extreme precision, reliability and guaranteed delivery times.

The humanoid robots designed by Oversonic Robotics integrate next-generation technologies and require mechanical components capable of ensuring:

Micrometric tolerances, essential for the seamless integration of electronics, sensors and structural parts.

Repeatability and consistent quality, even as production volumes increase.

Reliable lead times and scalability, to support continuous prototype development and testing.

In this context, the search for a manufacturing partner went beyond simple supply needs — it required a technological ally capable of guaranteeing high standards and production flexibility.

Weerg met Oversonic Robotics’ requirements with its digital, automated and 100% Made in Italy production model.

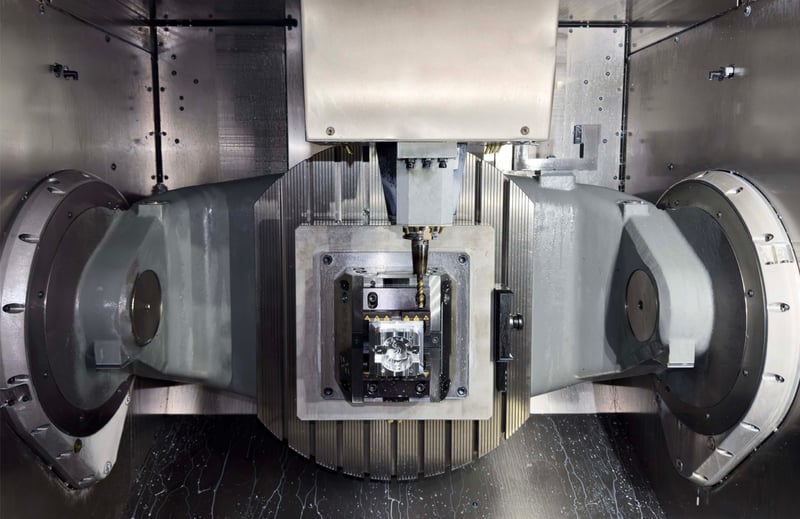

Thanks to a state-of-the-art 5-axis CNC machining centre, Weerg enabled ultra-precise production while keeping time and cost fully under control, even during scaling.

Key points of the collaboration:

Absolute precision: CNC machining with tight tolerances and dimensional control for every single part.

Instant scalability: from prototypes to small production runs, with unchanged processes and consistent quality.

On-time, traceable deliveries: digital job management and automated production flow scheduling.

100% Italian in-house production: full control over every stage, from machining to packaging.

This approach allowed Oversonic Robotics to meet all development deadlines and integrate Weerg’s CNC components into its humanoid robots without any revision or delay.

The collaboration between Oversonic Robotics and Weerg delivered concrete, measurable results:

Perfect on-time delivery, even for complex orders.

Consistent quality and full compliance with robotic assembly requirements.

Reduced lead times and optimised supply chain efficiency.

Seamless production scalability without any loss of precision.

Thanks to this synergy, Oversonic Robotics was able to accelerate the development of its humanoid robots, reduce time-to-market, and maintain exceptional mechanical standards.

The partnership between Weerg and Oversonic Robotics demonstrates how the integration of a forward-looking technological vision with a digital, scalable manufacturing capability can turn complexity into competitive value.

In a sector where precision is not an option but a necessity, Weerg confirms itself as the ideal partner for complex CNC projects, capable of guaranteeing:

Total process control

Reliable delivery times

Scalable production

Consistent industrial quality

The experience of Oversonic Robotics is clear evidence of how Weerg’s CNC technology can support the most innovative companies in developing highly complex technical projects.

Together, Weerg and Oversonic Robotics represent two Italian excellences that share the same vision: transforming technology into tangible progress through precision, reliability and innovation.

Discover how your company can also accelerate production with Weerg’s precision and scalability.

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

3 min read

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

3 min read

How Environmental Management System certification strengthens the quality of our production processes and the value we deliver to our partners