3 min read

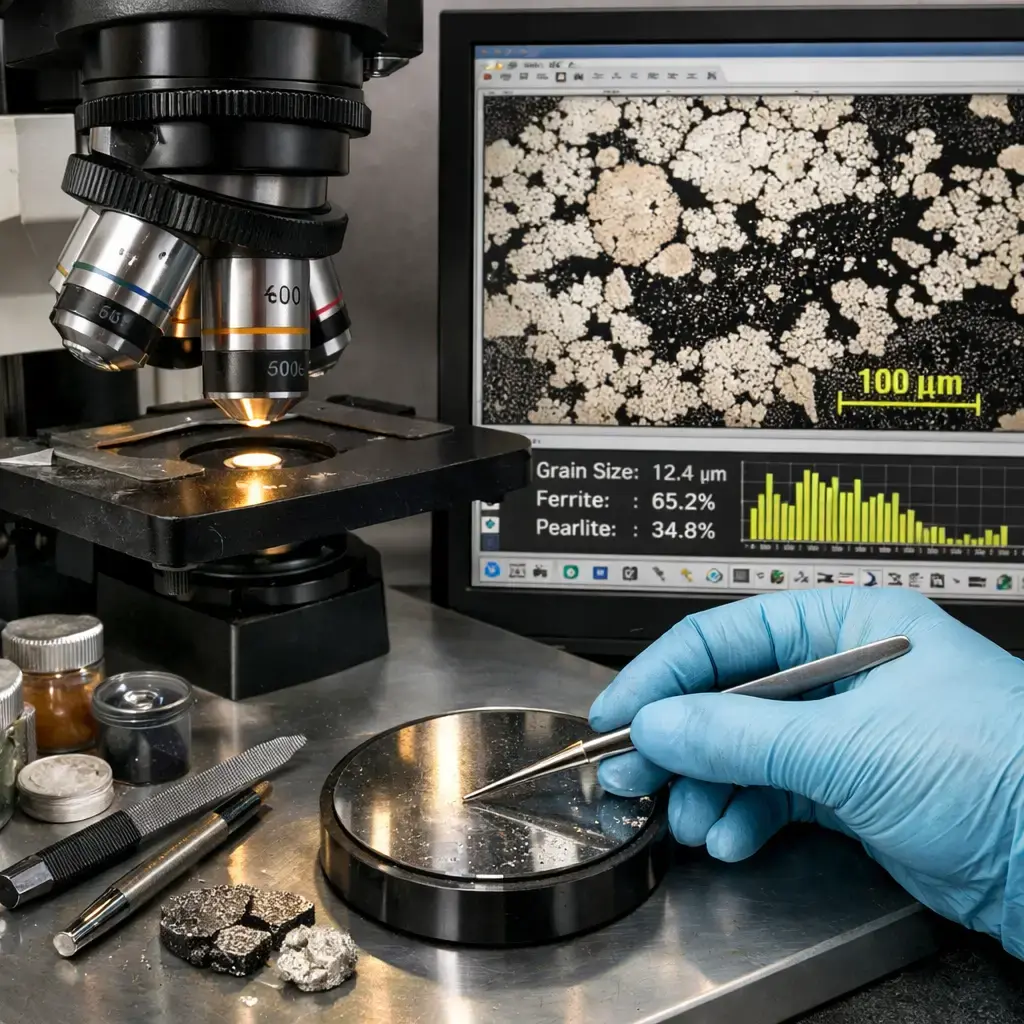

Metallographic Analysis: Microstructure and Quality Control

Metallographic analysis is a fundamental technique used to study the microstructure of metals and alloys. By observing a specially prepared sample...

Nylon is one of the most widely used plastic materials in the world.

Thanks to its combination of strength, light weight, flexibility and durability, it is used in sectors ranging from clothing to mechanical engineering, from automotive to 3D printing.

In this 2026 guide you will discover:

1. What nylon is

2. Why nylon is so widely used

3. The main applications of nylon

4. Why choose nylon instead of metal

5. Its limitations

6. Conclusion

Nylon is a synthetic polymer belonging to the polyamide family.

It was developed in the 1930s as an alternative to natural materials (such as silk) and quickly became established in industrial applications as well.

Common types include:

Each variant has specific properties, suitable for different uses.

Nylon is chosen because it offers a unique balance of:

high mechanical strength

good impact and wear resistance

low weight compared to metals

low coefficient of friction

resistance to oils and chemical agents

good thermal stability

ease of processing and moulding

These characteristics make it ideal for both functional and structural components.

Nylon originated specifically in textile sector and is still widely used for:

It is valued for its light weight, elasticity and tear resistance.

In the automotive industry, nylon is used to reduce weight and noise:

It provides resistance to heat, vibrations and chemical agents.

Nylon often replaces metal in parts subject to wear:

Main advantages include:

Nylon is found in a wide range of everyday items:

suitcase and backpack components

Its fatigue resistance makes it ideal for objects subjected to repeated stress.

Thanks to its insulating properties, nylon is used for:

terminal blocks

Flame-retardant grades are also available.

Some types of nylon are used in healthcare applications:

They are chosen for their strength, flexibility and biocompatibility (in specific grades).

In aerospace, nylon is used for:

lightweight brackets and supports

ducting

housings

non-structural components

It offers an excellent strength-to-weight ratio and vibration damping.

Nylon is one of the most important materials in industrial 3D printing.

It is used in technologies such as:

Common applications include:

housings and enclosures

jigs and fixtures

end-use production parts

The most commonly used grades are PA12 (well-balanced) and PA11 (more flexible and impact-resistant).

In many applications, nylon is an excellent alternative to metal because it:

is much lighter

does not rust

reduces vibration and noise

is cheaper to manufacture

offers greater design freedom

provides electrical insulation

In many cases provides comparable performance with additional advantages.

Despite its versatility, nylon has some limitations:

For this reason, choosing the correct type of nylon is essential.

Nylon is used in industry, automotive, electronics, medical, aerospace and 3D printing because it combines strength, light weight and durability.

It is one of the most versatile polymers ever developed and continues to play a central role in materials innovation.

Do you need to make nylon components with industrial quality?

Upload your 3D file and choose the nylon best suited to your application

Nylon is a synthetic polymer belonging to the polyamide family. It is a lightweight, strong and versatile material used in industrial, automotive, textile and 3D printing applications.

The most common types of nylon are:

Nylon 6 and Nylon 6,6 → industrial and mechanical uses

Nylon PA12 → balanced rigidity and flexibility, ideal for 3D printing

Nylon PA11 → more elastic and impact-resistant

Each type has different properties and is selected according to the application.

The main properties of nylon include:

high mechanical strength

good wear resistance

light weight

low coefficient of friction

chemical resistance

good thermal stability

These characteristics make it an excellent substitute for metal in many applications.

Nylon is recommended when you need a material that is:

strong yet lightweight

durable over time

suitable for parts subject to wear or friction

easy to machine or 3D print

It is ideal for gears, supports, housings, mechanical components and functional parts.

3 min read

Metallographic analysis is a fundamental technique used to study the microstructure of metals and alloys. By observing a specially prepared sample...

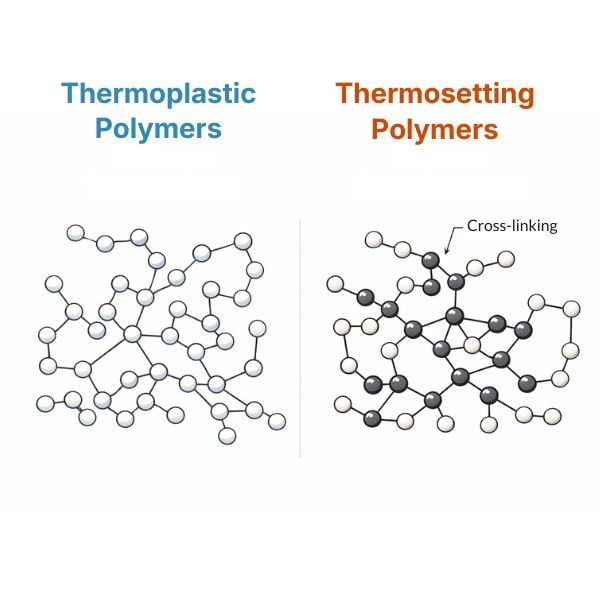

2 min read

Polymers represent one of the most versatile families of materials in modern industry. Within this category, the fundamental distinction is between ...

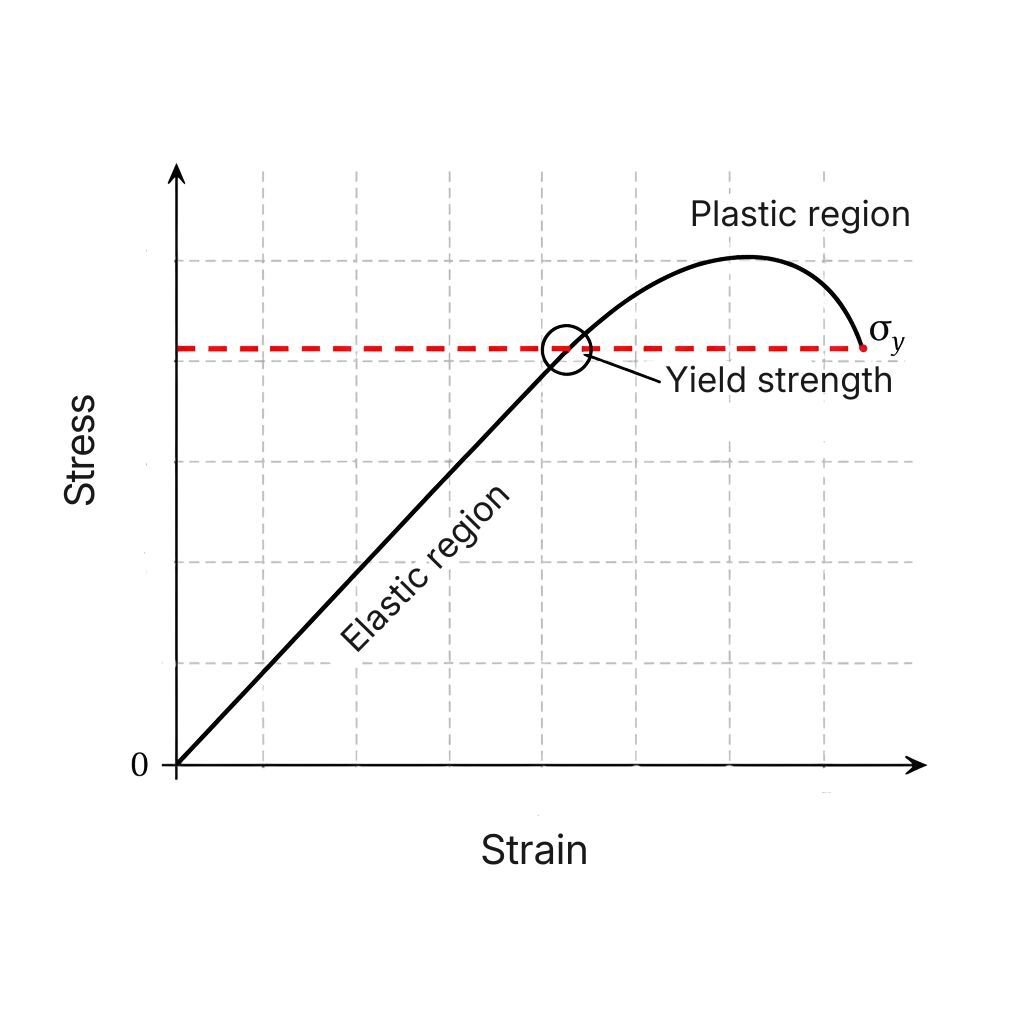

3 min read

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...