3 min read

Nylon: Uses, Industrial Applications and Advantages

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

3 min read

![]() Weerg staff

:

Jul 22, 2025

Weerg staff

:

Jul 22, 2025

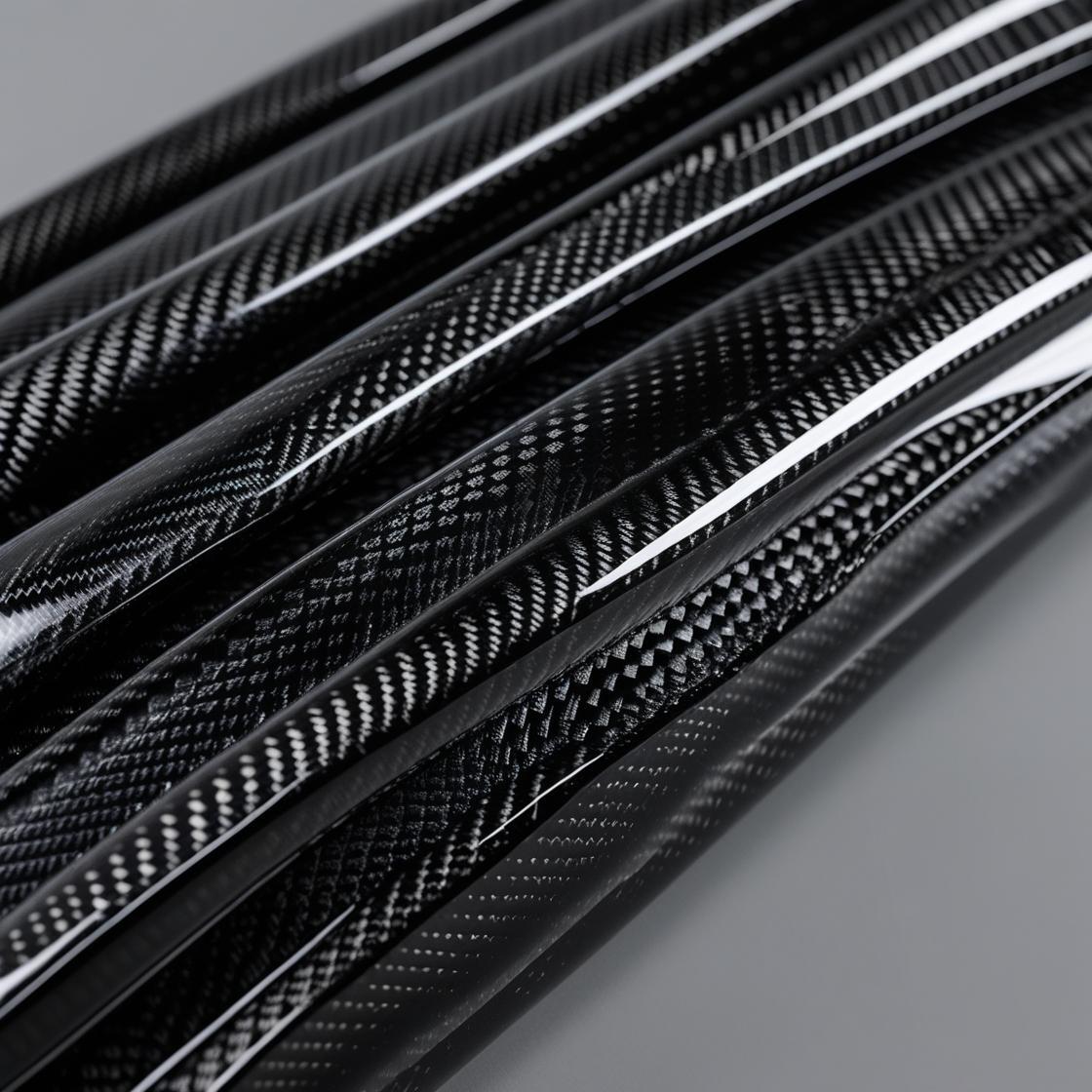

3D printing has revolutionised the manufacturing sector by enabling rapid and precise prototyping, as well as offering new opportunities in the production of high-performance components. Among the most innovative materials used in this technology are carbon fibre reinforced filaments, combining lightness, stiffness, and exceptional mechanical strength. Among the leading companies offering this technology, Weerg stands out for the quality and versatility of its carbon fibre composite materials, including nylon PA 12 CF, PA 6 CF, and PEEK CF.

Carbon fibre filament for 3D printing typically consists of a base polymer, such as PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), or more technical materials like nylon or PETG, reinforced with short carbon fibres. These fibres, integrated into the filament during the extrusion process, significantly increase the rigidity, mechanical strength, and lightweight nature of printed parts. The length and concentration of fibres vary according to filament type and the intended application, determining the different properties of the printed part.

Carbon fibre is renowned for its unique characteristics: extreme lightness, high tensile and compressive strength, low thermal expansion, and high structural rigidity. These properties make carbon fibre one of the most valued materials in industries such as automotive, aerospace, robotics, and competitive sports. Integrated into 3D printing filament, it enables the creation of components with performance comparable to parts produced using traditional methods.

In Weerg’s catalogue, PA 12 CF (Nylon 12 reinforced with carbon fibre) is one of the most popular choices. This material provides an optimal balance between low weight and structural strength. Due to the carbon fibre reinforcement, PA 12 CF greatly improves mechanical performance compared to traditional nylon, ensuring impact-resistant parts with high fatigue resistance and dimensional stability over time. It is ideal for creating functional parts under stress, such as mechanical tools, industrial robot components, and medical devices.

For even more demanding applications, PA 6 CF is an excellent alternative. This material, also within the nylon family, offers greater thermal resistance than PA 12 CF and has outstanding chemical and abrasion resistance properties. These features make it suitable for parts subjected to extreme environments, such as automotive components exposed to vibrations and high temperatures, or precision mechanical industry parts like guides, gears, brackets, and supports.

At the top of the carbon fibre material range is PEEK CF, one of the most advanced technical polymers available for 3D printing. Carbon fibre reinforced PEEK (Polyetheretherketone) is a high-performance solution, capable of withstanding extremely high temperatures (up to 260°C in continuous use), aggressive chemical agents, and exceptional mechanical loads. This material is widely used in aerospace, medical, and petrochemical sectors for critical, high-stress components such as valves, fittings, turbine components, and surgical instruments.

The primary advantages of carbon fibre filaments are their combination of lightness and strength. The printed parts feature high stiffness and a particularly favourable strength-to-weight ratio, making this material ideal for automotive, aerospace, drones, robotics, and high-performance sports equipment applications. Furthermore, carbon fibre imparts a unique aesthetic, characterised by a matte black finish with a slightly textured surface.

The presence of carbon fibres significantly enhances the dimensional stability of parts during printing, minimising thermal deformation (warping). This advantage facilitates the production of parts with complex and precise geometries.

In practical applications, 3D printing with carbon fibre filament is increasingly adopted in advanced industries. For instance, in the automotive sector, it enables the production of custom components for racing vehicles, reducing weight and enhancing mechanical strength. In aeronautics, carbon fibre printing allows the creation of lightweight and robust components suitable for drones and small aircraft.

In robotics, carbon fibre filament is highly valued for manufacturing robotic arms, joints, and other components requiring high stiffness and low weight for precise movement and durability. Moreover, in professional sports, this material is utilised to produce customised parts for bicycles, extreme sports equipment, and even components for sailing boats.

Another promising development involves filaments with continuous carbon fibres, offering superior mechanical properties compared to short-fibre filaments. However, printing with continuous fibres requires specialised machinery and increased complexity, thus remaining primarily an option in high-end industrial and prototyping contexts.

A further strength of Weerg is its online 3D printing service, significantly simplifying access to these advanced materials. Companies and designers can easily upload their CAD files onto the Weerg portal, quickly receive a quote, and choose from various customisation and finishing options. This operational simplicity combined with the quality of materials makes Weerg a strategic choice for those seeking to optimise production times and costs without compromising the final product's quality.

In conclusion, the use of carbon fibre reinforced filaments represents a significant qualitative leap in industrial 3D printing. Materials such as PA 12 CF, PA 6 CF, and PEEK CF offered by Weerg effectively meet the requirements of the most demanding sectors, ensuring superior results in mechanical performance, thermal stability, and long-term durability. Opting for these innovative materials means relying on cutting-edge technological solutions capable of revolutionising production processes and enhancing the competitiveness of modern businesses.

Ultimately, carbon fibre filament for 3D printing represents an advanced technological solution with enormous potential for innovative applications in key industries. Although its use requires specific technical skills and dedicated equipment, its excellent mechanical properties and the ability to create high-performance customised parts make this material one of the most promising choices for the future of additive manufacturing.

3 min read

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

3 min read

How Environmental Management System certification strengthens the quality of our production processes and the value we deliver to our partners

3 min read

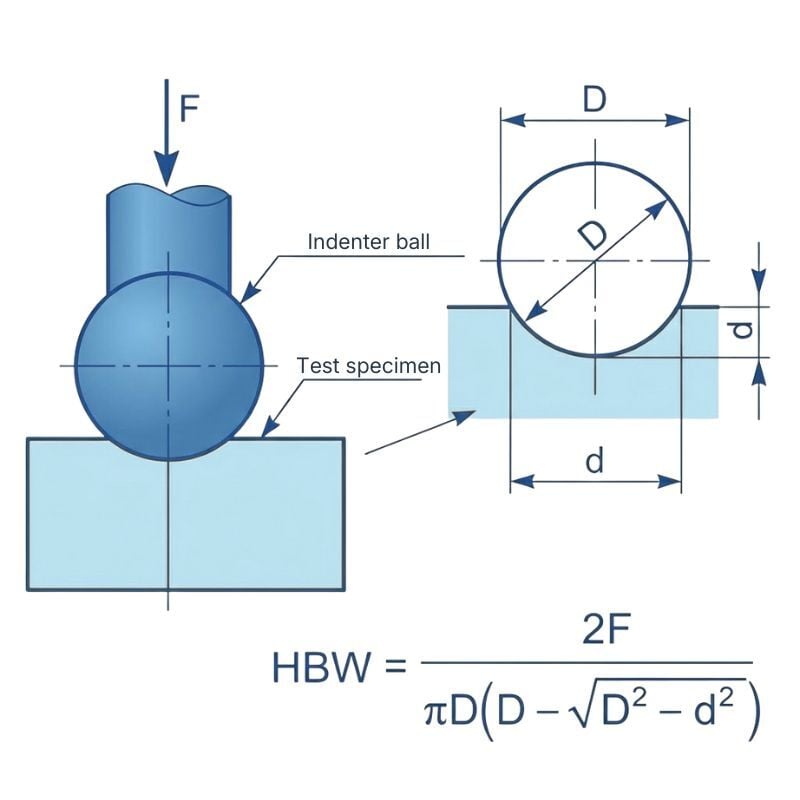

The Brinell test is one of the oldest and most reliable methods for measuring the hardness of materials, particularly metals.Even today it is widely...