3 min read

CBAM Regulation: What It Is, How It Works and Weerg Compliance

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

Material testing - Thermal Testing

The need for reliable data from repeatable tests that can be used by designers for material selection is the main reason why a number of standardized tests have been developed over time to characterise materials.

One such type of test is temperature testing. They are particularly important for understanding and describing the thermal behaviour of polymers, the properties of which can vary markedly with temperature. In these tests, the deformation and softening temperatures of polymeric materials are verified and quantified.

The sample of material to be tested is fixed in the lower part of the instrument where it is immersed in a heated bath. During the test, the temperature of the bath is increased in a controlled manner by a uniform ramp, while an indenter with an area of 1mm2 and a constant load towards the material is placed on the upper surface of the sample.

The indenter will sink into the material and when it reaches a depth of 1 mm, it will correspond to the temperature of the Vicat point of the material under test.

In the image it is possible to see a scheme of the test apparatus with the number 3 highlighting the punch that applies the load to the component, while on the right you can see a test machine with 6 independent stations. The reference standard for this test is ISO 306.

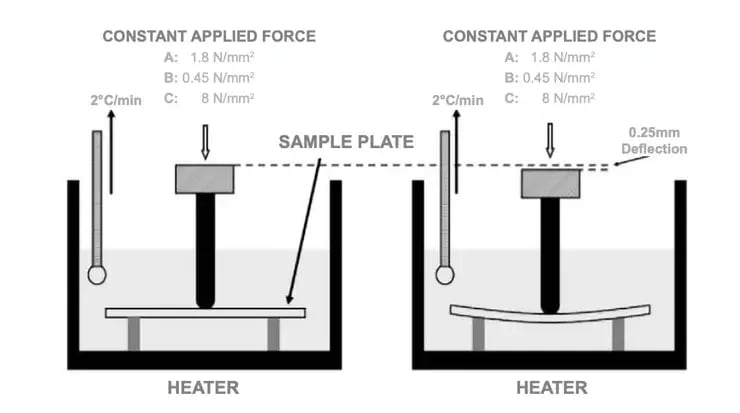

HDT method shows some similarities to the Vicat method as the specimen is placed in a thermostatic bath in this test as well. What changes, however, is the type of specimen, which is usually a prismatic rod, and the manner in which the component is stressed, as it is tested in flexion, with a constant applied force. The HDT temperature is reached when the deformation of the specimen exceeds 0.2% deflection.

In the picture we can see a specimen during the test (left) and at the end of the test (right) after a deformation of 0.25 mm. There are 3 different tests called A - B - C according to the loads to which the sample is subjected, respectively 1.8 MPa - 0.8 MPa - 8 MPa. The reference standard for this test is ISO 75. This test provides us with important information to identify the usable temperatures for a given material and also allows us to compare different materials in a direct and repeatable way.

The behaviour of a given material at different temperatures is extremely important for determining how to realise a design. That is why in Weerg, by testing all our materials, we have unique data which represents a performance benchmark between different materials. You can view the comparative material tables here.

If you still have doubts, questions or need additional information, our experts are available to support you in your choice: contact them here to discuss your project and your doubts about the material.

3 min read

The CBAM regulation (Carbon Border Adjustment Mechanism) represents one of the key pillars of the European strategy for industrial decarbonisation...

3 min read

Nylon is one of the most widely used plastic materials in the world.Thanks to its combination of strength, light weight, flexibility and durability,...

3 min read

How Environmental Management System certification strengthens the quality of our production processes and the value we deliver to our partners