3 min read

Yield Strength: Elastic Limit of Materials

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...

3 min read

![]() Fabio Trotti

:

Sep 15, 2021

Fabio Trotti

:

Sep 15, 2021

PEEK (Polyether Ether Ketone) is one of the most advanced engineering polymers available today.

Belonging to the polyaryletherketone (PAEK) family, it is often referred to as “the king of polymers” thanks to its exceptional combination of mechanical, thermal and chemical properties, which are difficult to match with other plastics.

Because of these characteristics, PEEK is widely used in highly demanding sectors such as aerospace, medical, automotive, electronics and chemical processing, often as a direct alternative to metal alloys.

PEEK is a semi-crystalline organic thermoplastic polymer belonging to the PAEK family.

Unlike common polymers such as PLA, ABS or PETG, PEEK is designed to operate under extreme conditions, maintaining stability even when exposed to:

high temperatures

heavy mechanical loads

chemically aggressive environments

Its molecular structure gives it outstanding stability and strength, while maintaining a much lower density than metals.

PEEK combines metal-like mechanical performance with the light weight of a polymer.

Tensile strength: up to approximately 100 MPa

Density: around 1.30 g/cm³ (for comparison: aluminium alloys ≈ 2.8 g/cm³)

Continuous operating temperature: up to 250–260 °C

High HDT (Heat Deflection Temperature)

Excellent fatigue and creep resistance

Outstanding chemical resistance

The combination of high mechanical strength and low density makes PEEK an excellent candidate for metal replacement, with the added benefit of enabling complex geometries through additive manufacturing.

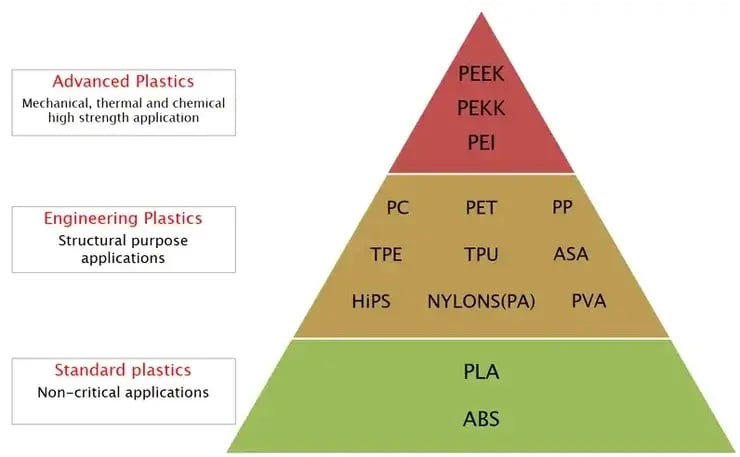

PEEK sits at the top of the engineering polymer hierarchy due to its balanced performance in:

thermal resistance

mechanical strength

dimensional stability

chemical resistance

biocompatibility

This makes it superior to most high-performance thermoplastics such as nylon, PPS or PEI when overall performance is required.

PEEK is challenging to process, but it can be successfully manufactured using industrial FDM 3D printing.

Nozzle temperature: above 400 °C

Heated chamber: at least 70 °C (often higher)

Industrial-grade printers only (not consumer machines)

These conditions are only achievable with dedicated industrial FDM systems designed specifically for high-performance polymers.

use of dedicated, easily removable support materials

elimination of traditional design constraints such as:

undercuts

internal channels

complex internal geometries

production of fully functional end-use parts, not just prototypes

PEEK can exist in two different crystalline states, which directly affect its performance.

Amber-coloured

Disordered molecular chains

Higher ductility

Better impact resistance

Lower maximum operating temperature

Ideal when:

impact resistance is required

some flexibility is beneficial

brittle behaviour must be avoided

Semi-Crystalline PEEK

Semi-Crystalline PEEKBeige / ivory colour

More ordered molecular structure

Improved mechanical and chemical properties

Stiffer and slightly more brittle behaviour

Operating temperatures up to ~250 °C

Preferred for:

high-temperature applications

structural components

harsh operating environments

| Property | Amorphous PEEK | Semi-Crystalline PEEK |

|---|---|---|

| Tensile strength [MPa] | ~70 | ~100 |

| Elongation [%] | ~12 | ~9 |

| HDT (0.8 MPa) [°C] | ~145 | ~180 |

| Behaviour | More ductile | More rigid |

| Ideal use | Impact resistance | High-temperature performance |

Thanks to its performance, PEEK is used in high-value, mission-critical applications.

structural brackets

housings and covers

thermal and electrical insulation

spinal implants

prosthetics

surgical instruments

sterilisation-resistant devices

(PEEK is considered an advanced biomaterial)

components near engines and exhaust systems

vibration- and heat-resistant parts

valves

seals

components exposed to aggressive fluids

PEEK is not a universal material and should be selected when:

standard polymers are insufficient

metals are too heavy

high performance is required in compact designs

complex geometries are needed

reliability is critical

PEEK represents the pinnacle of engineering polymers.

Its ability to combine high mechanical strength, extreme thermal resistance, chemical stability and low weight makes it a powerful alternative to metal alloys in many advanced applications.

Thanks to industrial FDM 3D printing, PEEK can now be used to produce custom, complex and fully functional components, reducing weight, lead times and design constraints.

If you believe PEEK is the right material for your project, you can review the technical data sheets and instantly estimate costs by uploading your 3D file.

3 min read

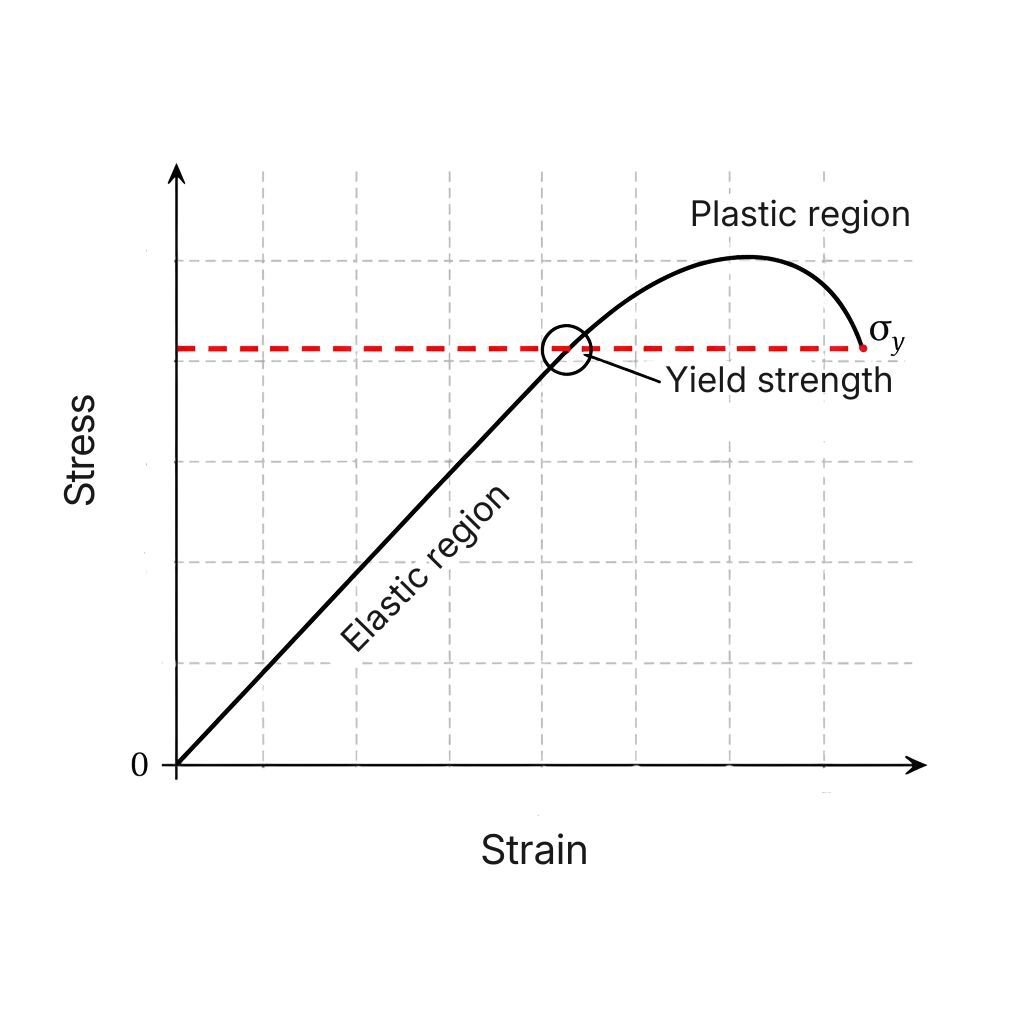

Yield strength is one of the most important mechanical properties of materials, especially in engineering, structural design, CNC machining and 3D...

4 min read

Metals are among the most important and widely used materials by humankind.From prehistory to Industry 4.0, they have supported technological...

2 min read

The coefficient of friction (μ) measures the resistance to sliding between two surfaces in contact. It is a key parameter in mechanical design...